4

VANESSA SERIES 30,000 TRIPLE OFFSET VALVE (TOV)

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

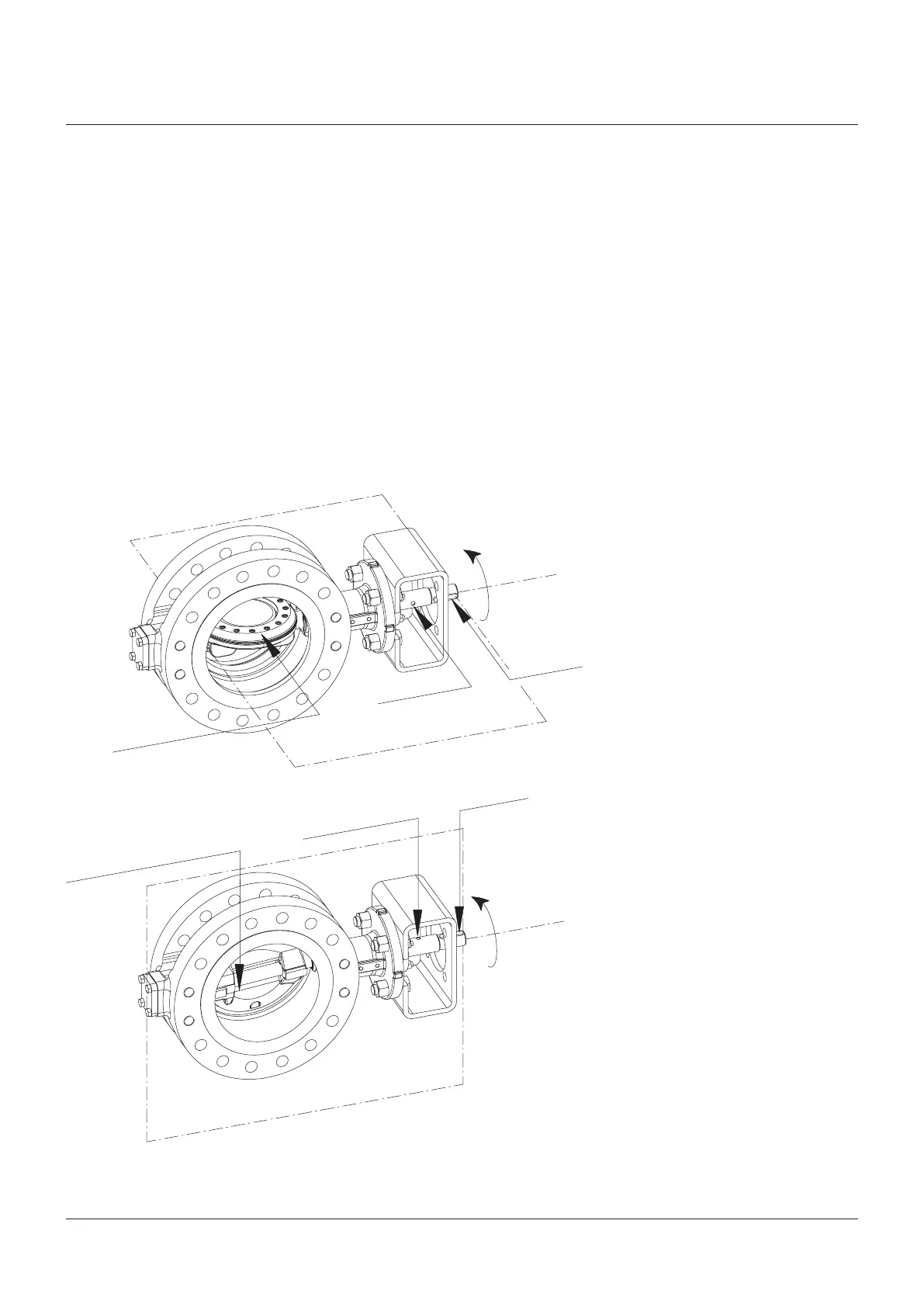

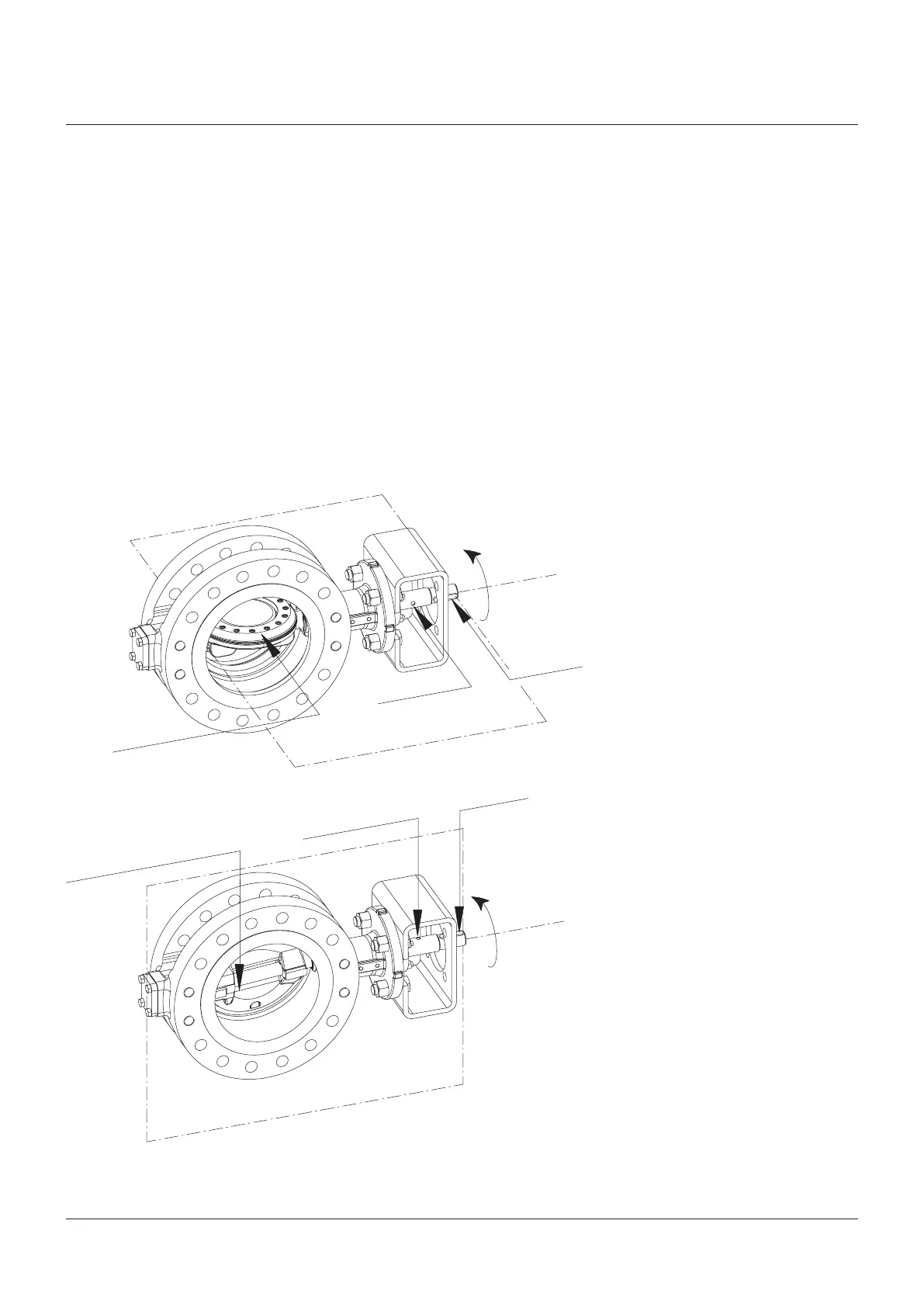

2.3 Valve verification

1. Tighten the packing box enough to prevent

shaft leakage. Over-tightening will decrease

packing component life and increase

operating torque.

2. Check the operability of the valve by stroking

it to “full open” and “full close”. To verify the

valve orientation, the disc position indicator

mark on the shaft (during the normal open

to close cycle) should rotate clockwise from

a position in line with the pipe (see figure3A)

to a position parallel to the pipe flanges

(seefigure 3B).

2.4 Commissioning

1. Whenever the piping system is pressurized

with water for testing or in case it has been

shut down after testing for a long time,

the following recommendations should

be adopted:

a. Use corrosion inhibitor with water to

pressurize the piping system.

b. After testing, the piping system should

be depressurized and the test water

completely drained.

c.

After testing, the valve must be operated

through a complete opening/closing cycle

and the disc should be left in half-open

position. Apply a film of protective oil in

the packing area by means of a paintbrush.

The protective oil must fill the area between

shaft and packing bushing.

FIGURE 3A

FIGURE 3B

Clockwise to close

Clockwise to close

Shaft key

Disc in open position

Disc in closed position

Disc position

indicator mark

Disc - shaft key and position indicator mark plane

Disc - shaft key and position indicator mark plane

Disc position indicator mark

Shaft key

2. The valve is fully metallic and typically

withstands the cleaning agents used for

metallic pipelines.

Loading...

Loading...