6.5 Safe stopping of the wind energy converter

The ENERCON wind energy converter can be stopped by manual intervention or automatically by

the control system.

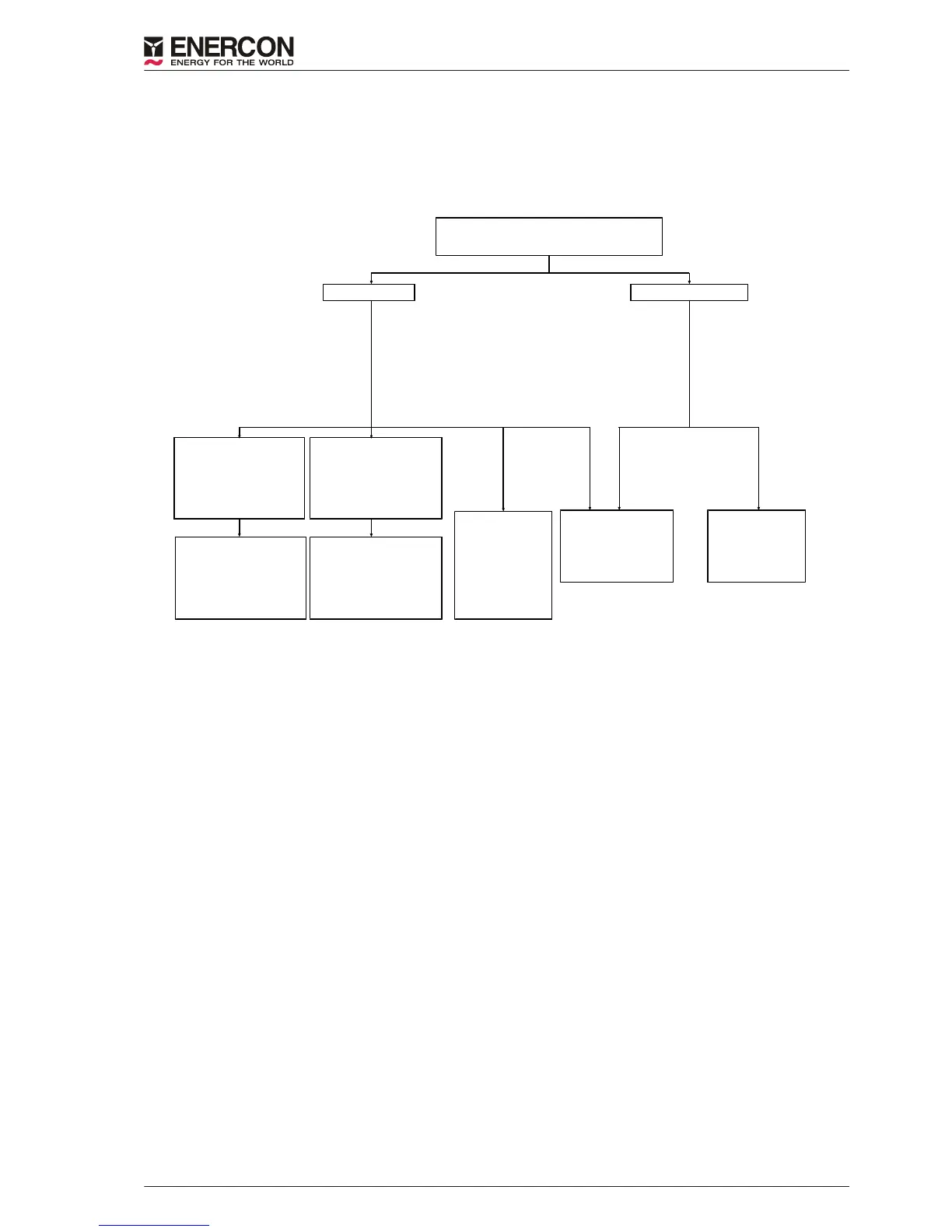

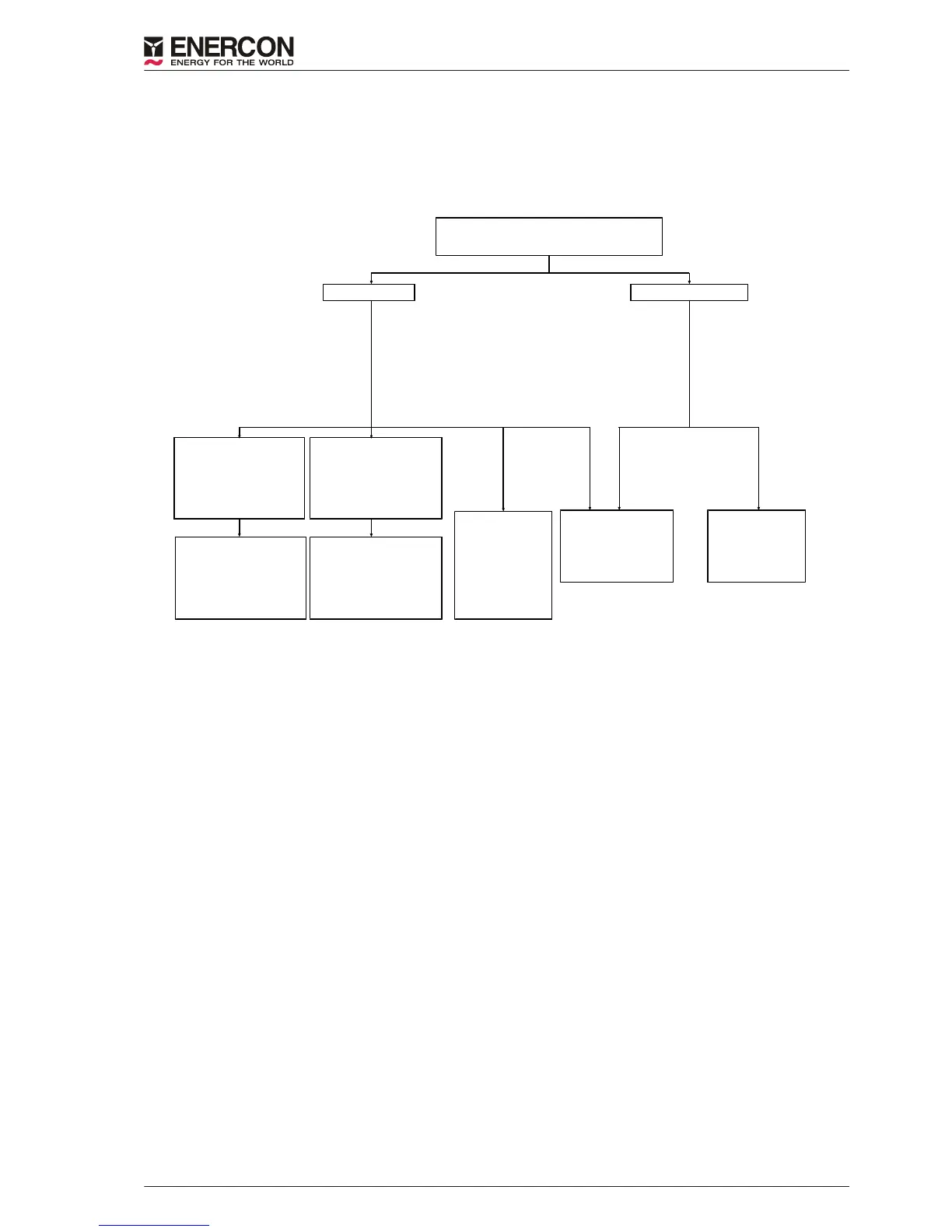

The causes are divided into groups by risk.

Fig. 5: Overview of stopping procedures

Stopping the wind energy converter by means of pitch control

In the event on a fault that is not safety-relevant, the WEC control system pitches the rotor blades

out of the wind, causing the rotor blades not to generate any lift and bringing the wind energy con‐

verter to a safe stop.

Emergency pitching

For emergency pitching, the pitch motors are supplied with power by the capacitor boxes. The rotor

blades move automatically and independently of each other into a position in which they do not

generate any lift; this is called the feathered position.

Since the three pitch units are interconnected but also operate independently of each other, if one

component fails, the remaining pitch units can still function and stop the rotor.

Emergency braking

If a person presses an emergency stop button, or if the rotor lock is used while the rotor is turning,

the control system initiates an emergency braking procedure.

This means that in addition to the emergency pitching of the rotor blades, the rotor brake is ap‐

plied. The rotor is decelerated from rated speed to a standstill within 10 to 15 seconds.

Control system

D0376616-2 / DA 17 of 21

Loading...

Loading...