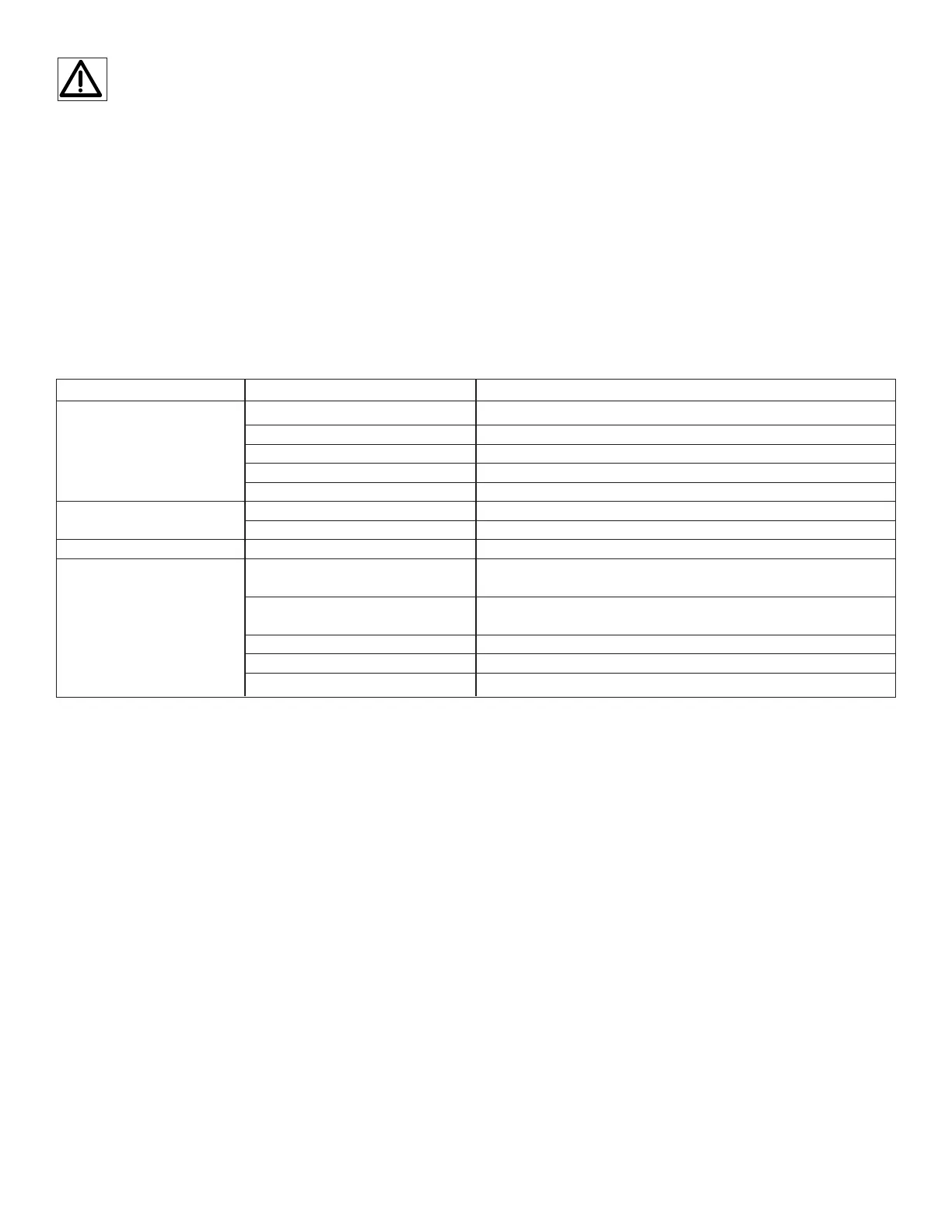

Problem Cause Correction

Jack will not rise, rises Load is too heavy. Do not attempt to lift more than rated capacity.

part way or rises in

Release valve open. Close release valve.

spurts.

Low fluid level. Add fluid. See Preparation – Section 4.2, Adding Fluid.

Air in system. Remove air. See Preparation – Section 4.3, Removing Air.

Plunger binding. Have jack serviced by an authorized ENERPAC Service Center.

Jack rises, but will Load is too heavy. Do not attempt to lift more than rated capacity.

not hold.

Seal/seat failure. Have jack serviced by an authorized ENERPAC Service Center.

Jack leaks hydraulic fluid, Seal failure. Have jack serviced by an authorized ENERPAC Service Center.

Plunger retracts slowly. Release valve closed. Open release valve slowly.

See Operation – Section 5.3, Lowering the Load.

Reservoir is over-filled. With jack in the upright position and no load, remove fill

plug and allow oil to drain out of fill hole.

Air in system. Remove air. See Preparation – Section 4.3, Removing Air.

Seal failure. Have jack serviced by an authorized ENERPAC Service Center.

Return spring worn or damaged. Have jack serviced by an authorized ENERPAC Service Center.

WARNING: Make sure dirt or other contaminants do

not enter the reservoir while the fill plug is removed.

3. Lay the jack on its back and drain the fluid into a proper

receptacle.This fluid MUST be disposed of in accordance

with your local regulations.

4. If the drained fluid is contaminated, flush the reservoir

with clean ENERPAC hydraulic fluid before refilling.

5. Stand the jack upright and slowly add ENERPAC

hydraulic fluid to the reservoir until the fluid is even with

the bottom of the fill plug hole.

6. Pump the jack socket by hand to extend the piston without

a load. If the proper amount of fluid is in the reservoir, the

jack socket will be almost impossible to pump near the top

of the stroke.

7. Check fluid level. Add if necessary. (See Section 4.2)

8. If it is necessary to remove air from the system see

Preparation - Removing Air. (See Section 4.3)

6.3 Storage and Handling

Store the Track Jack in an upright position, in a place where it

is protected from the elements, abrasive dust and damage.

The Track Jack should be stored where it is safe from dust,

moisture and physical damage. Use only approved ENERPAC

replacement and repair parts. Use the carrying handle to

transport the Track Jack from site to site. DO NOT carry the

jack by the jack handle.

7.0 Troubleshooting Table

44

Loading...

Loading...