13

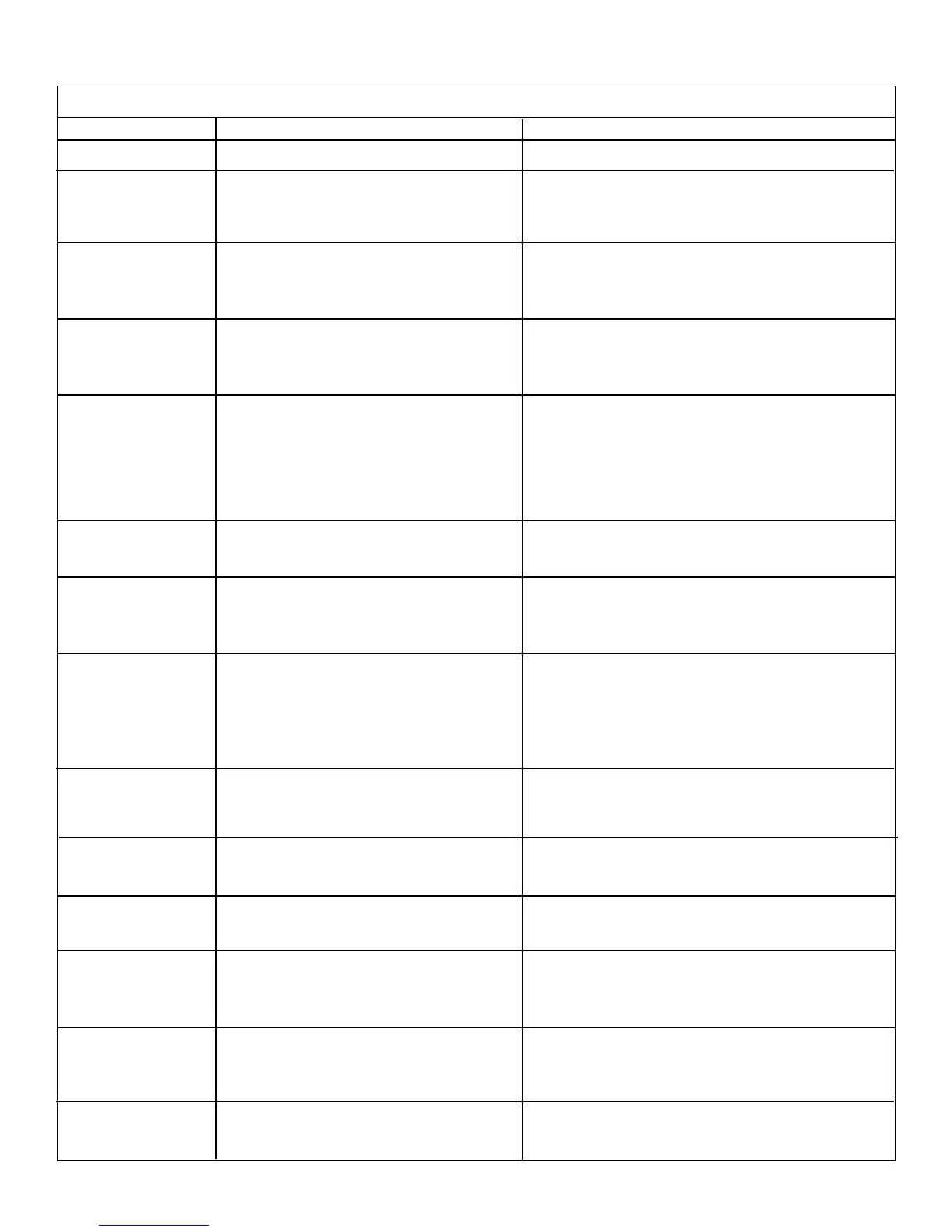

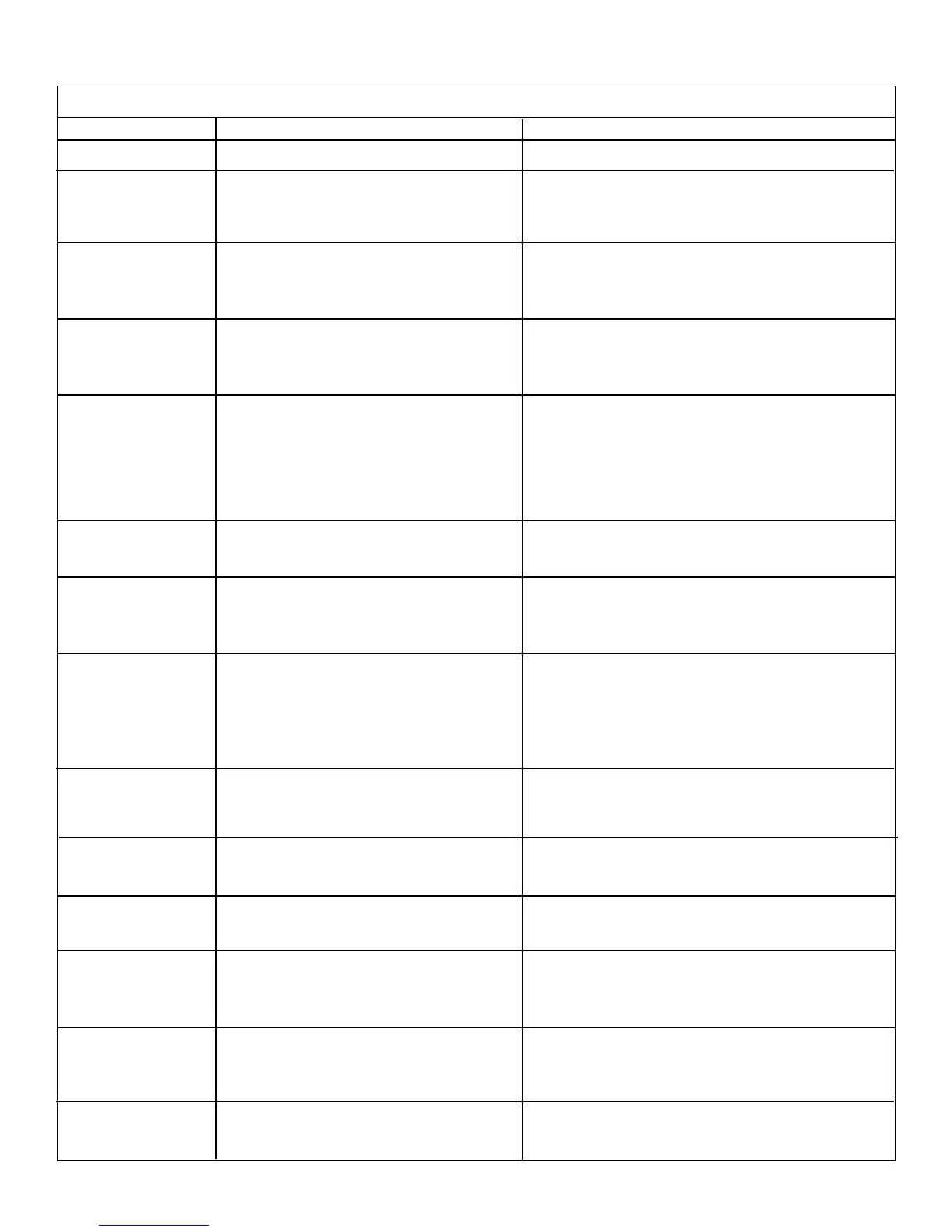

Trouble-shooting Guide

Problem Possible Cause Action*

* For LCD versions, also see sections 6.2 Fault Conditions, 6.3 Warning Conditions and 6.4 LCD Menus.

Pump will not start

Pendant does not function

Motor stops under load

Electric valve will not

operate

Pump fails to build

pressure or less than full

pressure

Pump builds full pressure,

but load does not move

Cylinder drifts back on its

own

Single-acting cylinder will

not return

Double-acting cylinder will

not return

Pump runs hot

Pump pressure goes

above "HI PRESS" value

AUTOMODE does not

work correctly with VE33

or VE43 valves

After boot-up LCD shows

"P switch open"

LCD display shows

"FILTER"

Fault condition

Pump in local mode

Pendant damage

Low voltage

No power or wrong voltage

Solenoid cable disconnected or damaged

Valve out of adjustment

Low oil level

Relief valve set too low

External system leak

Internal leak in pump

Internal leak in valve

Internal leak in system component

Load greater than cylinder capacity at full pressure

Flow to cylinder blocked

External system leak

Internal leak in a system component

Non-load holding valve used

No load on a "load return" cylinder

Return flow restricted or blocked

Locking valve used

Valve malfunction

Cylinder return spring broken

Return flow restricted or blocked

Locking valve used

Valve malfunction

Advance or retract flow restricted

High ambient temperature

Cylinder comes to a sudden stop (i.e., strokes out)

Pressure transducer installed in pressure port other

than GA

Pressure switch circuit is open and press transducer

is installed

Loose jumper on power board

See section 5.0 Operation and 6.2 Fault Conditions for details

See Section 6.4G, Local Menu

See Section 6.4I, Diagnose Menu

See authorized service center

See Section 6.2B and 6.3A

Turn off other electric loads

Use heavier gauge extension cord

Connect to correct power source per pump name plate

Connect, repair, or replace cable

See authorized service center

Add oil per section 4.4

Adjust per section 5.7

Inspect and repair or replace

See authorized service center

See authorized service center

See authorized service center

Reduce load or add cylinder capacity

Check hydraulic couplers for full engagement

Inspect all hydraulic connections and replace or repair

See authorized service center

See authorized service center

Add load

Check couplers for full engagement

Run motor while retracting

See authorized service center

See authorized service center

Check couplers for full engagement

Run motor while retracting

See authorized service center

Check couplers for full engagement

Install heat exchanger for hydraulic oil

Set user adjustable relief valve 200 psi above "HI PRESS" valve

to redirect excess oil flow.

Move pressure transducer to “GA” (see section 8.1). Change

microprocessor setting to “GB” (see Authorized Service

Center).

Check power board pressure switch jumper for being lose or

missing (see Fig. 11).

Remove pressure switch or pressure transducer from pump.

Check power board for lose or missing jumper at filter (see fig.

11).

Loading...

Loading...