8

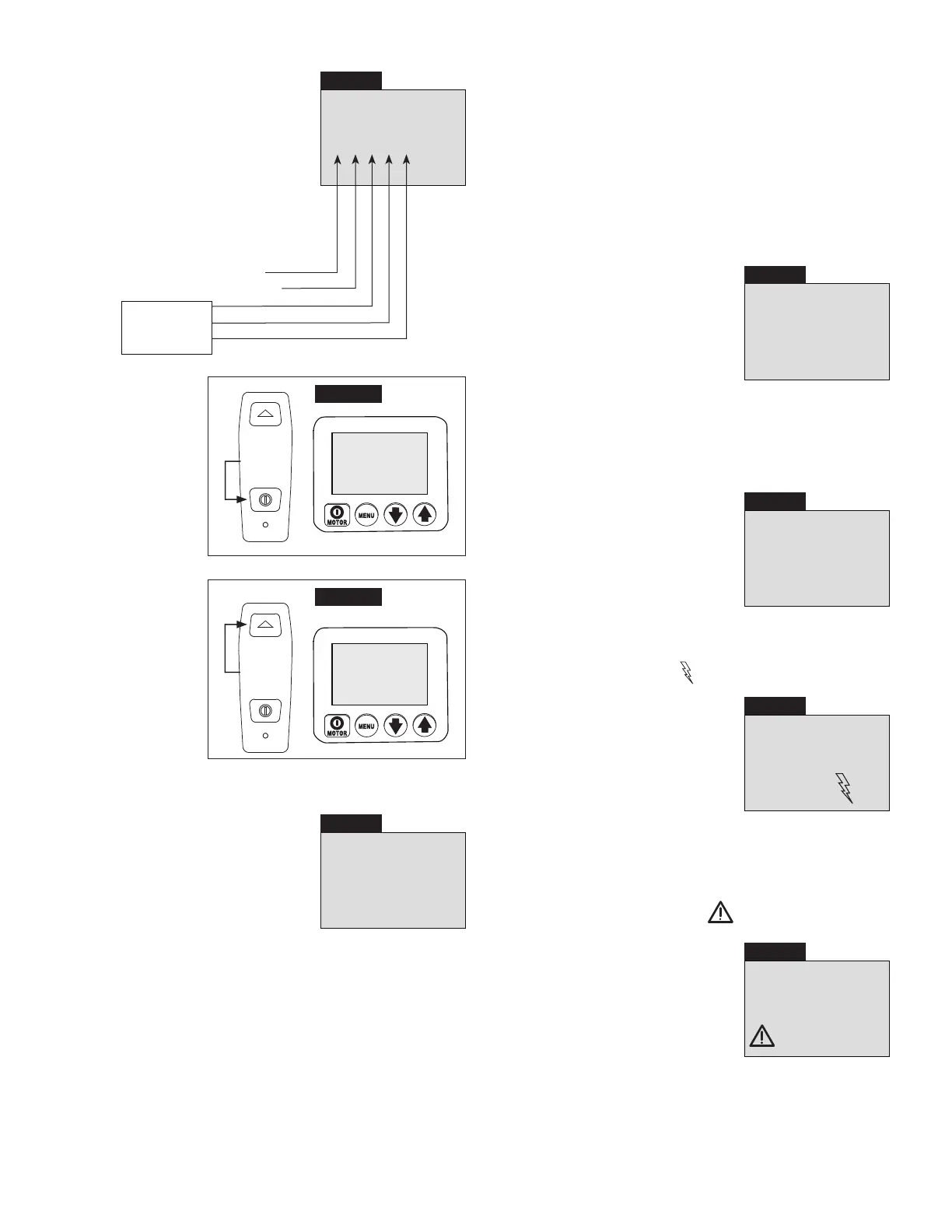

6.5 O “Diagnose” Menu

DIAGNOSE

00001

Pendant on/o button

Pendant advance button

(not used

on this pump

version)

Screen 15

PSI MPa

BAR Nm

Ft-lb

(See Screen 15) This screen allows

the operator to troubleshoot various

pendant problems. If the number “1”

does not appear when a pendant

button is pushed, problems with

the pendant button switches and/or

pendant cord may be present (See

Screens 16 and 17). Use Local mode

to operate pump until the problem can

be corrected. Refer to QRC step #11.

Press

Screen 16

DIAGNOSE

01001

PSI MPa

BAR Nm

Ft-lb

Diagnose screen

with pendant

on/o button

pushed.

Press

Screen 17

DIAGNOSE

10001

PSI MPa

BAR Nm

Ft-lb

Diagnose screen

with pendant

advance button

pushed

.

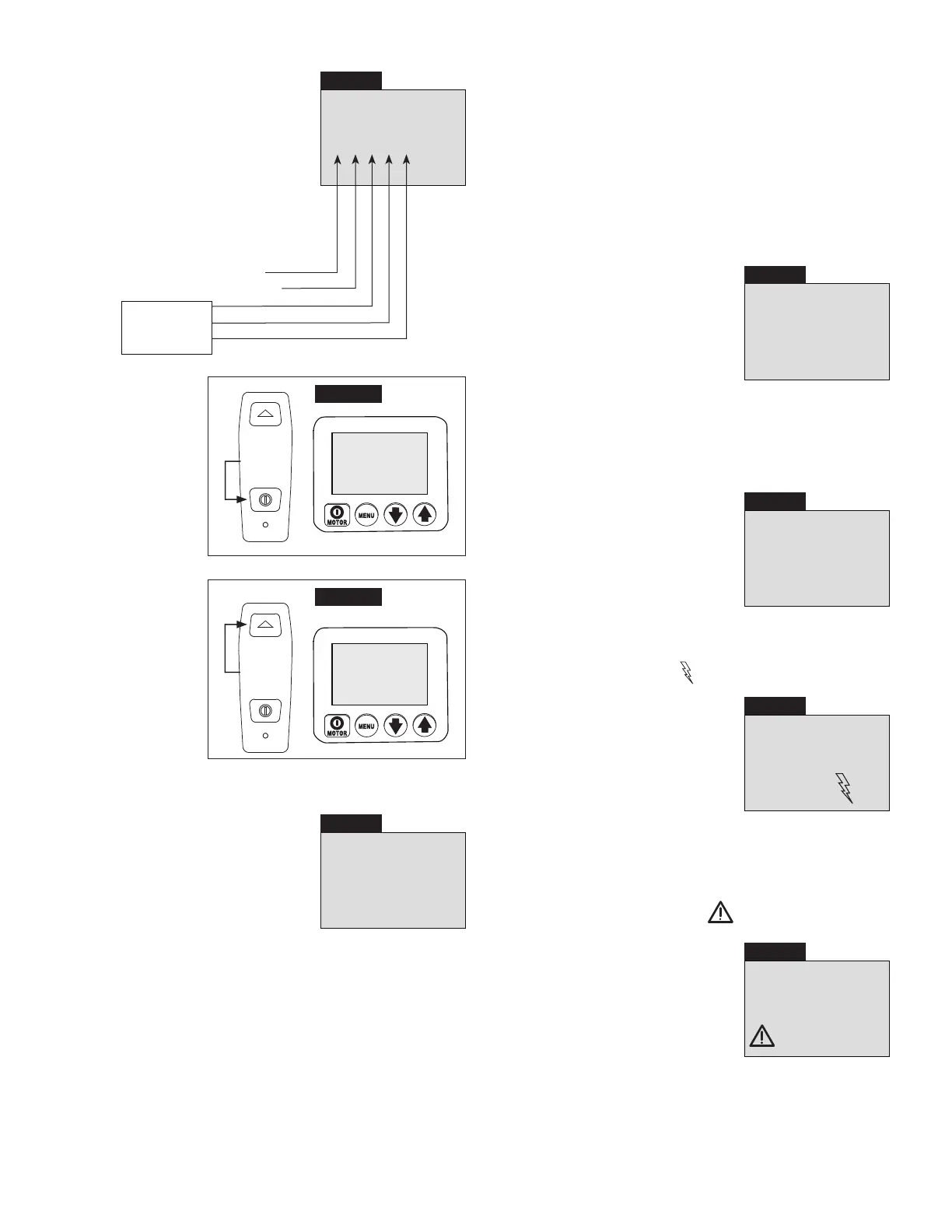

6.5 P “Calibration” Menu

0

SET

Screen 18

PSI

(See Screen 18) This screen allows

the operator to adjust the pressure

value shown on the LCD to match a

master gauge.

To access the Calibration menu, first

go to the Units menu.

Then, press and hold the shroud

Motor on/o button for 7 seconds. ENTRY CODE will appear

on the LCD.

Then, press and hold both the Down Arrow and Up Arrow

buttons for 7 seconds. CAL PT A will appear on the LCD.

See Table 2, “ZU4 Pressure Transducer Calibration”, located

near the end of this document. Follow the steps in the table to

perform calibration procedures.

6.6 LCD Fault Conditions

Any fault condition will shut down the pump and prevent it

from starting.

6.6 A Clearing a Fault Condition from the LCD

After the fault causing problem has been corrected, clear the

fault message from the LCD by disconnecting electrical power

from the pump. Wait until all characters clear the LCD (~ 20

seconds), then reconnect power.

6.6 B Power O Fault

Display: “POWER OFF”

OFF

Screen 19

See Screen 19) The Power O fault

occurs when the AC line power drops

to 65% or less of nominal voltage. The

pump will automatically shut-o the

valve solenoid and motor, and “Power

O” will be displayed on the LCD.

Note: The Power O message will also

appear for several seconds after the

pump has been disconnected from

electrical power.

6.6 C Button Fault

Display: “BUTTON FAULT”

FAULT

Screen 20

(See Screen 20) The Button fault

occurs when the microcontroller

detects that any button has been

pressed during the boot sequence

or if the shroud Motor on/o button

has been pressed for more than

3 seconds.

6.6 D Motor Overload Fault

Display: “MTR OVLD FAULT”

and “Motor Overload”

MTR OVLD

FAULT

Screen 21

MOTOR

OVERLOAD

(See Screen 21) The Motor Overload

fault occurs when the electrical current

draw exceeds the pre-set limit of

the pump’s internal circuit breaker.

The circuit breaker will automatically

reset in about 2 to 3 minutes after

the condition has been corrected.

However, before the pump can be

restarted, the operator must clear the fault by disconnecting

and reconnecting electrical power as described in Section 6.6 A.

6.7 LCD Low Voltage Warning

Display: “LOW VOLT” and “Low Voltage”

Screen 22

LOW

VOLTAGE

(See Screen 22) A “Low Voltage”

condition is defined as an operating

condition when the AC line power is

at or below 80% of nominal voltage.

While running the pump under this

condition, the “Low Voltage” signal will

flash on the LCD and the Low Voltage

hours will be counted and stored by

the microcontroller.

Loading...

Loading...