10

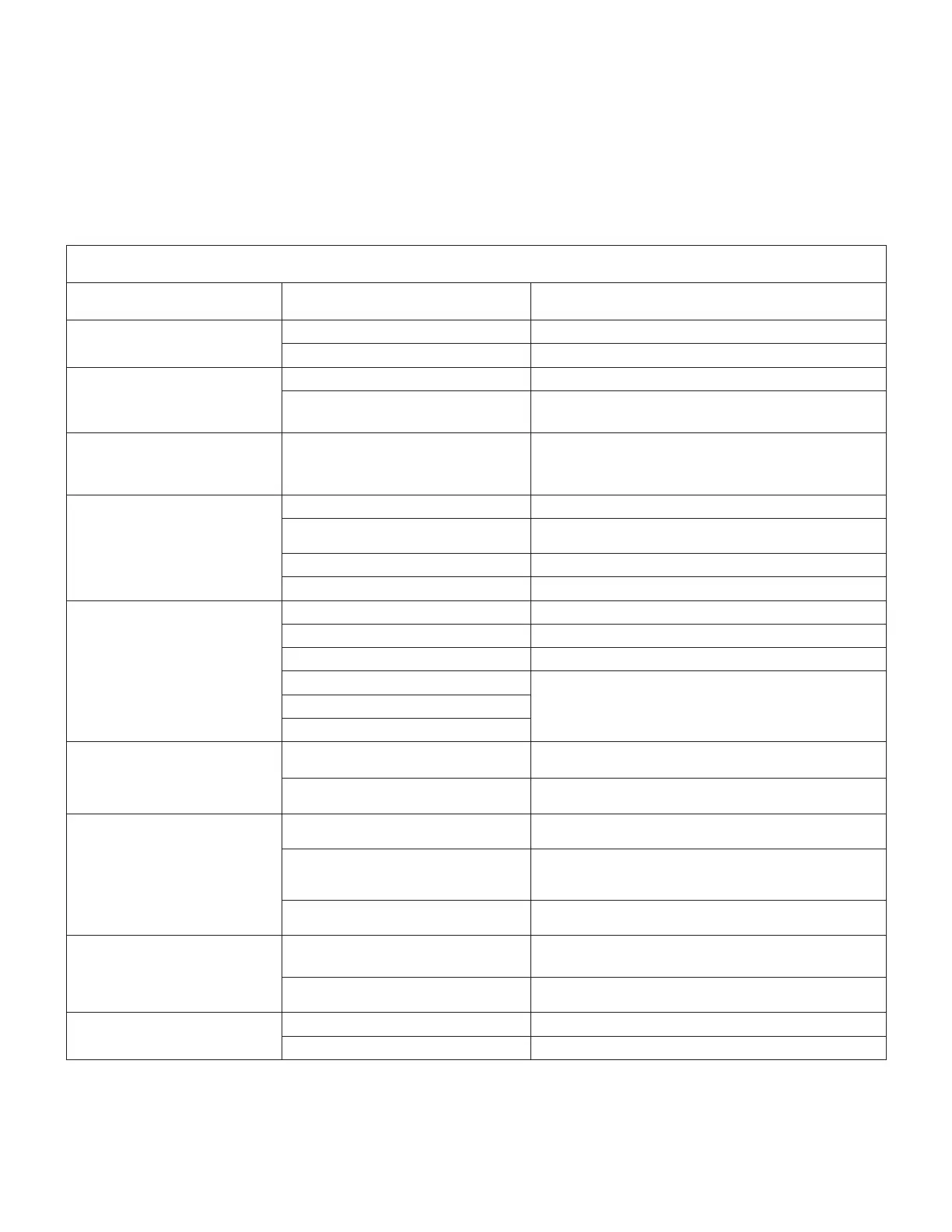

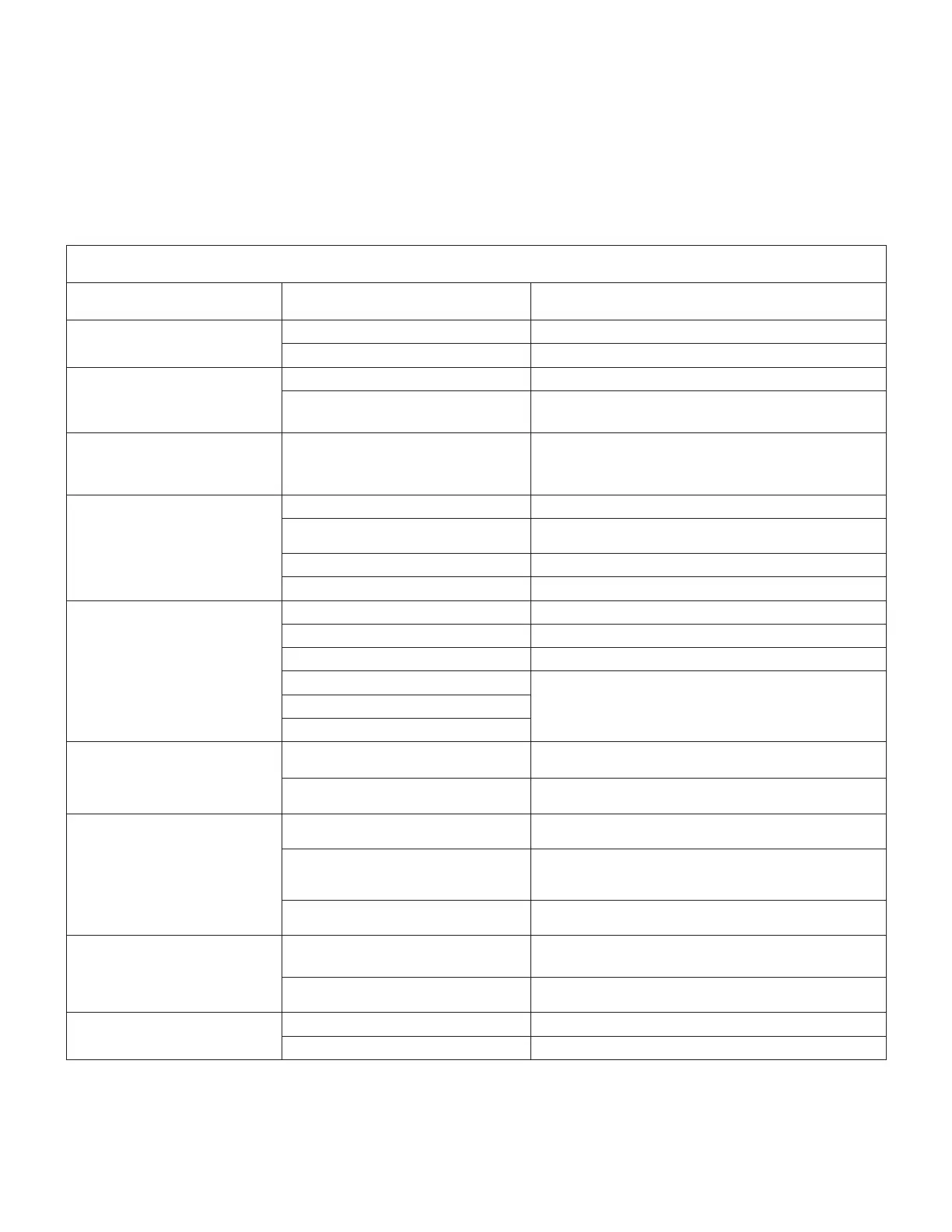

Troubleshooting Guide*

Problem Possible Cause Action

Pump will not start. Fault condition. See Section 6.6, LCD Fault Conditions.

Motor brushes worn to end of life. See Section 7.3, Motor Brush Replacement.

Pendant does not function. Pump in LOCAL mode. See Section 6.5 M, Local Menu.

Pendant damaged. See Section 6.5 O, Diagnose Menu.

See authorized service center.

Motor stops under load. Low voltage. See Section 6.5 J and 6.7 .

Turn o other electric loads.

Use heavier gauge extension cord.

Solenoid valve will not operate. No power to pump or wrong voltage. Connect to correct power source per pump nameplate.

Solenoid cable disconnected or damaged. Connect, repair, or replace cable.

Solenoid coil not operational. See authorized service center.

Valve out of adjustment or malfunctioning. See authorized service center.

Pump fails to build pressure or less

than full pressure.

Low oil level. Add oil per Section 4.3.

Relief valve set too low. Adjust per Section 5.2.

External system leak. Inspect and repair or replace.

Internal leak in pump.

See authorized service center.

Internal leak in valve.

Internal leak in system component.

Pump builds full pressure, but torque

wrench does not advance.

Torque greater than wrench capacity at full

pressure.

Use torque wrench with larger capacity.

Advance flow to wrench restricted or

blocked.

Check couplers for full engagement per Section 4.5.

Torque wrench does not auto-cycle

or cycles erratically.

Automode is OFF. Turn Automode ON. See sections 5.3 and 6.5 D.

Relief valve setting at or below “HI PRESS”

value (or below the corresponding pressure

setting for the selected torque).

Increase relief valve setting. See Section 5.2.

HI PRESS setting below 1400 PSI [96 bar]. Raise HI PRESS setting above 1400 PSI [96 bar].

Torque wrench will not retract. Return flow line restricted or blocked. Check couplers for full engagement per Section 4.5.

Run motor when retracting.

Valve malfunction. See authorized service center.

Pump runs hot. Advance or retract flow restricted. Check couplers for full engagement per Section 4.5.

High ambient temperature. Install heat exchanger.

* Refer as needed to sections 6.6 and 6.7 for LCD fault codes and warnings.

9.0 TROUBLESHOOTING

Only qualified hydraulic technicians should service the pump

or system components. A system failure may or may not be

the result of a pump malfunction. To determine the cause of

the problem, the complete system must be included in any

diagnostic procedure.

The following information is intended to be used only as an aid in

determining if a problem exists. For repair service, contact your

local authorized service center.

Loading...

Loading...