CONSTRUCTION FEATURES • CFR

©December, 2005 Environmental Technologies, Inc. • CFR Catalog

5

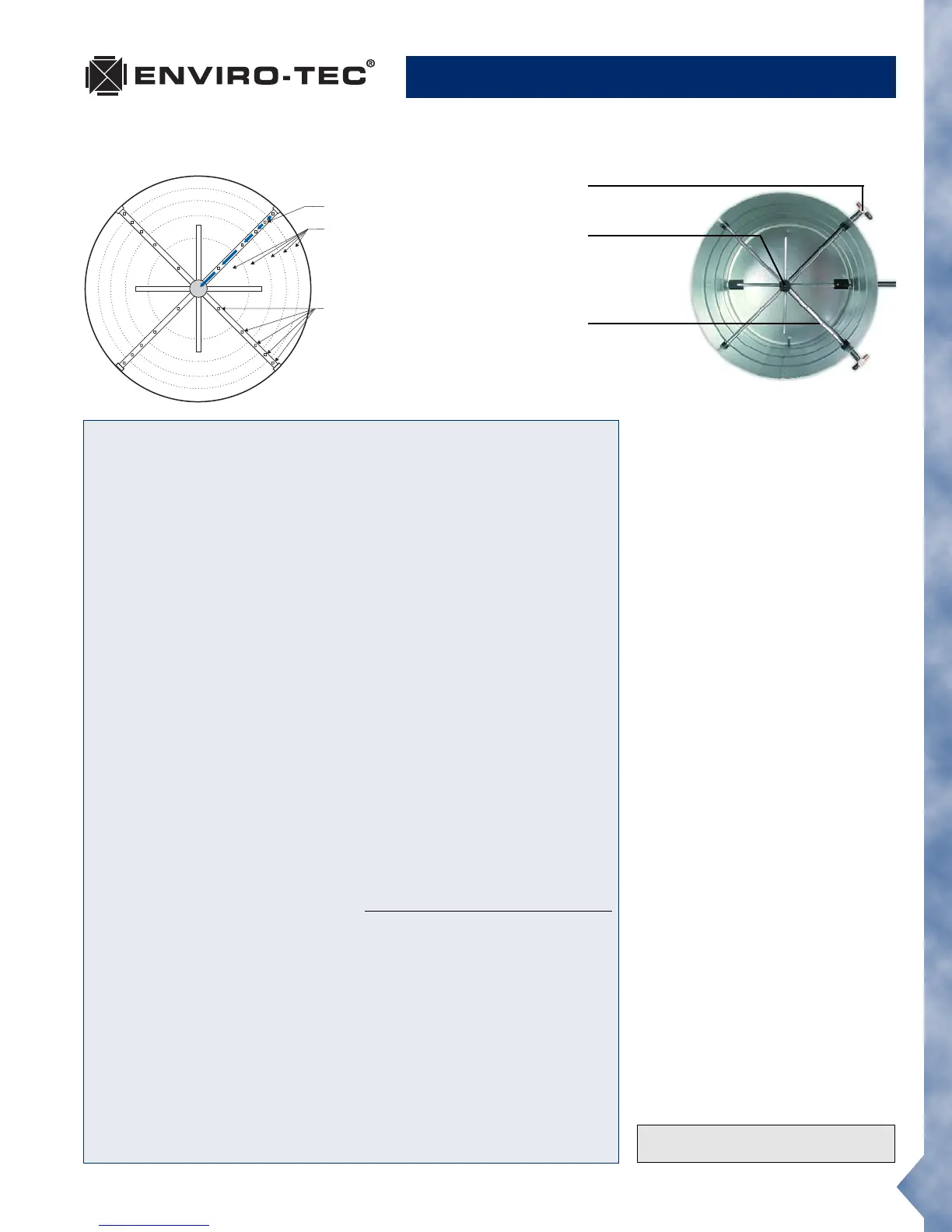

Each pressure input signal is routed

to the center averaging chamber

Equal concentric circular areas

Sizes 6 & 8: 3 Circles

Sizes 10 & 12: 4 Circles

Sizes 14 & 16: 5 Circles (shown)

Total pressure measured at the center

of each concentric circle for maximum

accuracy, as outlined in ASHRAE

Fundamentals Handbook.

Sizes 6 & 8: 12 Sensing Points

Sizes 10 & 12: 16 Sensing Points

Sizes 14 & 16: 20 Sensing Points

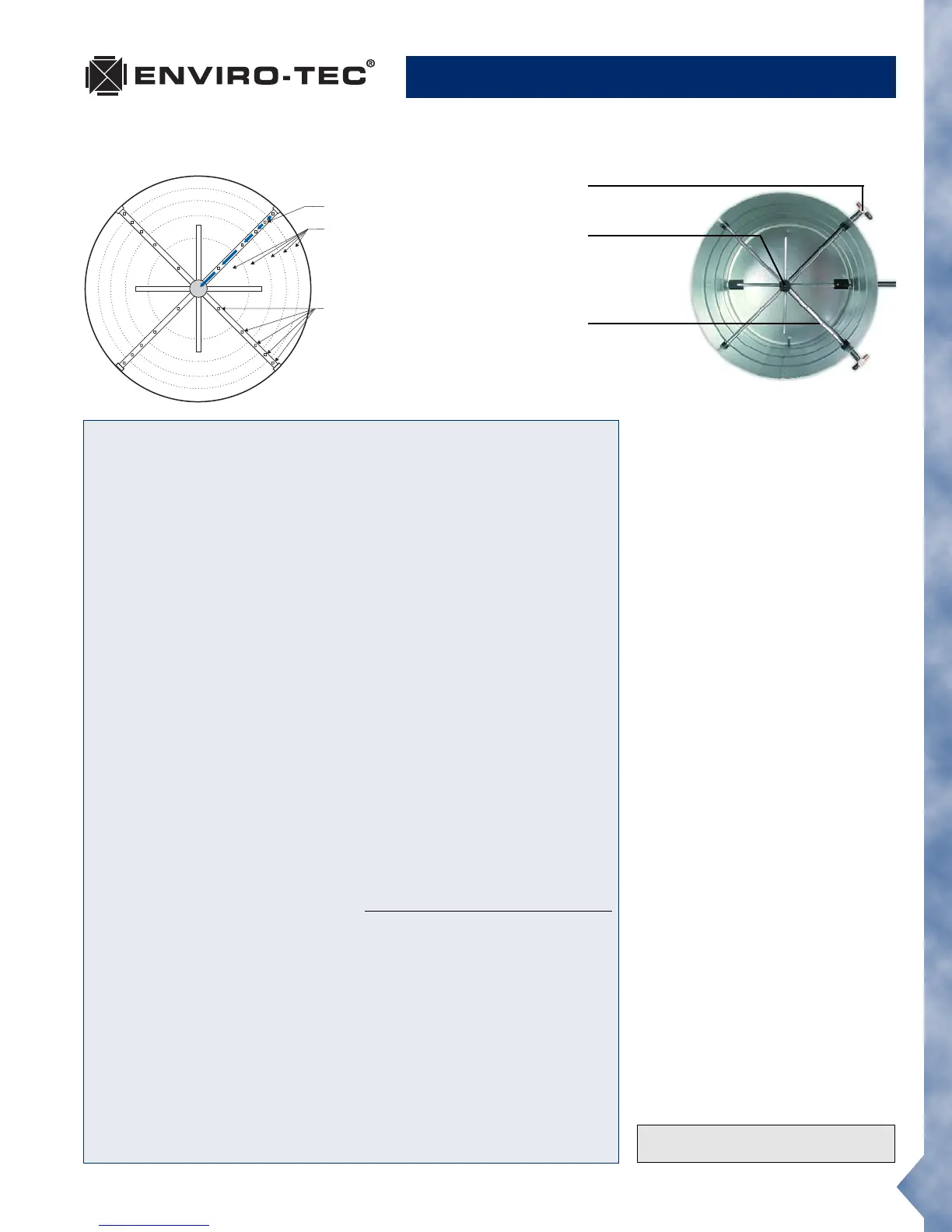

Brass field pressure

measuring tap

Airfoil shaped

averaging

chamber for low

pressure loss

and noise

Pressure output is

routed behind

probe to minimize

pressure loss

and noise

Accurate and Energy-Saving Airflow Control

With The Patented FlowStar™ Sensor

Many VAV terminals waste ener-

gy due to an inferior airflow

sensor design that requires the

minimum CFM setpoint to be

much higher than the IAQ cal-

culation requirement. This is

common with interior spaces

that will be effected year round.

These inferior VAV terminals waste

energy in several ways. First, the

primary air fan (e.g. AHU) supplies

more CFM than the building

requires. The higher minimum

CFM setpoint overcools the zone

with VAV terminals without inte-

gral heat. To maintain thermal

comfort a building engineer would

need to change the minimum set-

point to zero CFM compromising

indoor air quality. Inferior VAV

terminals with integral heat pro-

vide adequate comfort in the

space but waste significant ener-

gy as energy is consumed to

mechanically cool the primary

air only to have more energy

consumed to heat the cooled

primary air. Significant energy sav-

ings is obtained with proper

sizing and by making sure

approved VAV terminals are capa-

ble of controlling at low CFM

setpoints, providing the mini-

mum ventilation requirement.

Currently, most DDC controllers

have a minimum differential pres-

sure limitation between 0.015" and

0.05" w.g. The major DDC man-

ufacturers can control down to

0.015" w.g. An airflow sensor that

does not amplify, e.g., a Pitot tube,

requires about 490 FPM to devel-

op 0.015" w.g. differential

pressure. The FlowStar develops

0.015" w.g. pressure with only 290

FPM on a size 6 terminal and less

than 325 FPM for a size 16. Con-

sequently, VAV terminals utilizing

a non-amplifying type sensor

could have minimum CFM's that

are well over 50% higher than an

ENVIRO-TEC terminal. Many air-

flow sensors provide some degree

of amplification simply due to the

decrease in free area of the inlet

from large area of the sensor.

These VAV terminals still require

minimum CFM's up to 30% high-

er than an ENVIRO-TEC terminal,

have higher sound levels, and

higher pressure drop requiring

additional energy consumption at

the primary air fan.

A VAV system designed with

ENVIRO-TEC terminals con-

sumes significantly less energy

than a comparable system with

competitor's terminals. The

FlowStar airflow sensor reduces

energy consumption by allowing

lower zone minimum CFM set-

points, greatly reducing

or eliminating “reheat”, and by

imposing less resistance on the

primary air fan.

The ENVIRO-TEC

®

air valve features the Flow-

Star™ airflow sensor which has brought new

meaning to airflow control accuracy. The

multi-axis design utilizes between 12 and

20 sensing points that sample total

pressure at center points within equal

concentric cross- sectional areas, effectively

traversing the air stream in two planes. Each

distinct pressure reading is averaged with-

in the center chamber before exiting the

sensor to the controlling device.

This sensor adds a new dimension to

signal amplification. Most differential

pressure sensors provide a signal between

.5 and 2 times the equivalent velocity

pressure signal. The FlowStar™ provides

a differential pressure signal that is 2.5 to

3 times the equivalent velocity pressure

signal. This amplified signal allows more

accurate and stable airflow control at low

airflow capacities. Low airflow control is

critical for indoor air quality, reheat

minimization, and preventing over cool-

ing during light loads.

Unlike other sensors which use a large

probe surface area to achieve signal

amplification, the FlowStar™ utilizes an

unprecedented streamline design which

generates amplified signals unrivaled in the

industry. The streamlined design also

generates less pressure drop and noise.

The VAV schedule should specify the

minimum and maximum airflow setpoints,

maximum sound power levels, and

maximum air pressure loss for each terminal.

The specification for the VAV terminal must

detail the required performance of the

airflow sensor. For maximum building

occupant satisfaction, the VAV system

designer should specify the airflow sensor

as suggested in the Guide Specifications

of this catalog.

FlowStar™ Airflow Sensor

Patent #5,481,925

Loading...

Loading...