APPLICATION AND SELECTION • CFR

©December, 2005 Environmental Technologies, Inc. • CFR Catalog

7

Achieving acceptable sound levels

in the zone begins with a proper-

ly designed central fan system

which delivers relatively quiet air to

each zone.

Supply Duct Pressure. One primary

factor contributing to noisy systems

is high static pressure in the primary

air duct. This condition causes high-

er sound levels from the central fan

and also higher sound levels from

the terminal unit, as the primary air

valve closes to reduce the pressure.

This condition is compounded when

flexible duct is utilized at the ter-

minal inlet, which allows the central

fan noise and air valve noise to break

out into the ceiling cavity and then

enter the zone located below

the terminal. Ideally, the system

static pressure should be reduced

to the point where the terminal unit

installed on the duct run associat-

ed with the highest pressure drop

has the minimum required inlet pres-

sure to deliver the design airflow

to the zone. Many of today’s

HVAC systems experience 0.5" w.g.

pressure drop or less in the main

trunk. For systems that will have

substantially higher pressure

variances from one zone to anoth-

er, special attention should be paid

to the proper selection of air ter-

minal equipment.

To date, the most common approach

has been to select (size) all of the ter-

minals based on the worst case

(highest inlet static pressure) condi-

tion. Typically, this results in 80% (or

higher) of the terminal units being

oversized for their application. This

in turn results in much higher equip-

ment costs, but more importantly,

drastically reduced operating

efficiency of each unit. This conse-

quently decreases the ability to

provide comfort control in the zone.

In addition, the oversized terminals

cannot adequately control the min-

imum ventilation capacity required

in the heating mode.

A more prudent approach is to uti-

lize a pressure reducing device

upstream of the terminal unit on

those few zones closest to the

central fan. This device could sim-

ply be a manual quadrant type

damper if located well upstream of

the terminal inlet. In tight quarters,

perforated metal can be utilized as

a quiet means of reducing system

pressure. This approach allows all

of the terminal units to experience

a similar (lower) inlet pressure.

They can be selected in a consistent

manner at lower inlet pressure

conditions that will allow more

optimally sized units.

Inlet duct that is the same size as

the inlet collar and as straight as pos-

sible will achieve the best acoustical

performance. For critical applica-

tions, flexible duct should not be

utilized at the terminal inlet.

Zoning. On projects where inter-

nal lining of the downstream duct

is not permitted, special consider-

ations should be made to assure

acceptable noise levels will be

obtained. In these cases, a greater

number of smaller zones will help

in reducing sound levels. Where pos-

sible, the first diffuser takeoff

should be located after an elbow

or tee and a greater number of small

necked diffusers should be uti-

lized, rather than fewer large necked

diffusers.

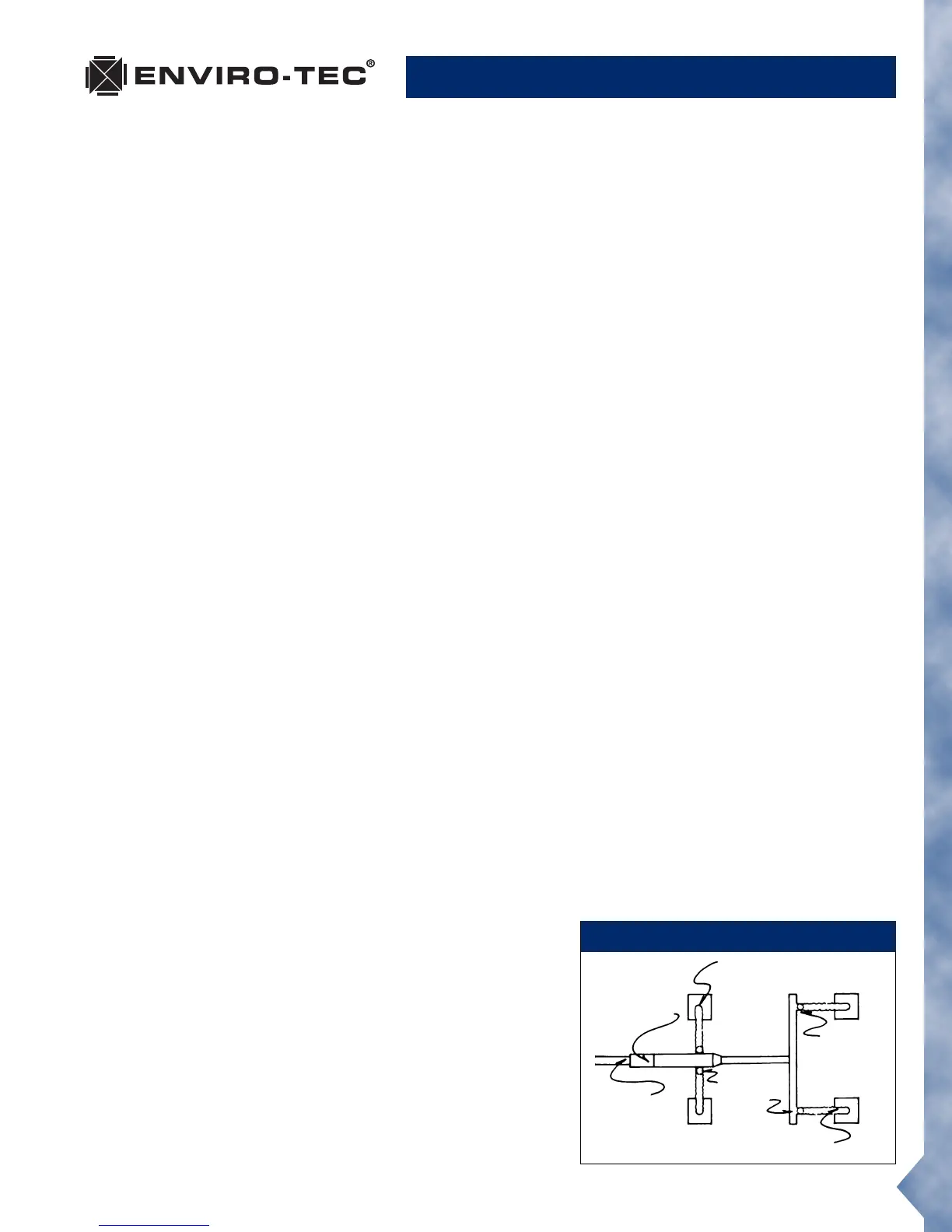

The downstream ductwork should

be carefully designed and

installed to avoid noise

regeneration. Bull head tee

arrangements should be

located sufficiently down-

stream of the terminal

discharge to provide an

established flow pattern

downstream of the fan.

Place diffusers downstream

of the terminal after the

airflow has completely

developed.

Downstream splitter dampers can

cause noise problems if placed

too close to the terminal, or when

excessive air velocities exist. If tee

arrangements are employed,

volume dampers should be used in

each branch of the tee, and bal-

ancing dampers should be provided

at each diffuser tap. This arrange-

ment provides maximum flexibility

in quiet balancing of the system.

Casing radiated sound usually dic-

tates the overall room sound levels

directly below the terminal. Because

of this, special consideration should

be given to the location of these

terminals as well as to the size of

the zone. Larger zones should have

the terminal located over a corri-

dor or open plan office space and

not over a small confined private

office. Fan powered terminals

should never be installed over

small occupied spaces where the

wall partitions extend from slab-to-

slab (i.e. fire walls or privacy walls).

Fan Terminal Isolation. Model CFR

fan terminals are equipped with suf-

ficient internal vibration dampening

means to prevent the need for addi-

tional external isolation. Flexible

duct connectors at the unit dis-

charge typically do more harm

than good. The sagging membrane

causes higher air velocities and

turbulence, which translates into

noise. Furthermore, the discharge

noise breaks out of this fitting

more than with a hard sheet metal

fitting.

IDEAL DUCT DESIGN

Small Necked Diffusers

High Quality

VAV Terminal

with Low

Sound Levels

Minimum

Required

Inlet Static

Pressure

Multiple

Branch

Take-Offs

Damper

Located at

Take-Off

Short Length of

Non-Metallic Flexible Duct

Loading...

Loading...