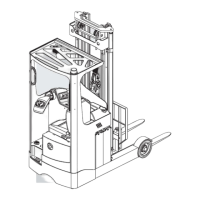

Chapter 1 Stacker Description Page: 7 Application Describes the stacker as a four-wheel, tiller-guided electric stacker designed for lifting and transporting palletised goods on level floors.

Assemblies Illustrates and lists the main components of the electric pallet stacker with item numbers for reference.

Conditions of Use Specifies the acceptable ambient temperature range for operation and conditions requiring special equipment or authorization.

Stacker Data Plate Details Explains the fields and information found on the stacker's data plate, including product name, serial number, and capacity.

Capacity Chart Explanation Describes how to interpret the capacity chart, which shows the relationship between load center and weight of loads.

Chapter 2 Operation Page: 16 Operator Safety Regulations Outlines essential safety rules for operators, including authorization, responsibilities, unauthorized use, damage reporting, and hazardous areas.

Controls and Displays Identifies and explains the function of various controls and display instruments on the stacker, such as Emergency Stop and battery indicator.

Starting Up the Stacker Details the pre-operation checks and the procedure for safely switching on and starting the stacker.

Battery Discharge Indicator Explains the LED indicators for battery residual capacity, their colours, and the conditions they represent.

Operating Hours Display Describes the LCD display for operating hours, indicating the range and what activity is logged.

Power Up Test Details what the display shows on power up and explains the low voltage protection function of the vehicle.

Troubleshooting Guides users on identifying and rectifying common faults or operational issues with the stacker, providing possible causes and actions.

Chapter 4 Stacker Maintenance Page: 29 Maintenance Safety Regulations Covers safety protocols for maintenance personnel, including lifting, jacking, cleaning, and handling electrical systems and welding.

Servicing and Inspection Highlights the importance of regular servicing and inspection, defining service intervals (W, A, B, C) and initial run-in period checks.

Maintenance Checklist Provides a detailed checklist of inspection and maintenance tasks categorized by system (Brake, Electrics, Power Supply, Travel, etc.) with service intervals.

Lubrication Schedule Illustrates the lubrication points on the stacker and indicates where hydraulic oil and transmission oil should be checked and filled.

Fuels, Coolants, and Lubricants Lists the types of fuels, coolants, and lubricants required for the stacker, along with handling instructions and their specific uses.

Preparing for Maintenance Details essential preparations before maintenance, including parking securely, disconnecting the battery, and securing raised components.

Removing Front Panel Provides step-by-step instructions for safely removing the front panel of the stacker.

Removing Drive Panel Details the procedure for removing the drive panel, including tiller positioning and screw removal.

Replacing the Drive Wheel Details the procedure for replacing the drive wheel, emphasizing that this must be performed by authorised service personnel.

Checking Hydraulic Oil Level Explains how to check the hydraulic oil level, including identifying the level display and when to perform the check.

Gauze Filter Maintenance Details the steps for flushing or replacing the gauze filter, including preparation and assembly procedures.

Checking Electrical Fuses Outlines the process for checking electrical fuses, including their ratings and replacement if necessary, referencing a table for details.

Recommissioning Lists the essential checks and operations required to recommission the stacker after cleaning or repair work.

Prior to Decommissioning Details necessary measures to take before decommissioning, including cleaning, checking brakes, and lubricating components.

During Decommissioning Specifies actions to be taken during decommissioning, such as regular battery charging to prevent self-discharge.

Restoring After Decommissioning Provides steps for restoring the stacker to operation after a decommissioning period, including cleaning, lubrication, and starting procedures.

Regular Safety Checks Mandates annual safety inspections and checks after unusual incidents, conducted by qualified personnel to ensure operational safety.

Final Decommissioning and Disposal Specifies that final decommissioning and disposal must comply with national regulations, particularly for batteries, fuels, and electronic systems.