11

the pusher leg, or when there is a tendency to jam� When the trig-

ger is released, the feed control setting is activated again�

Oil regulating valve

Oil dosing is controlled by means of a screwdriver�

Check that sufficient lubrication is obtained by putting your hand

in front of the exhaust port while adjusting the regulating valve�

If the hand is covered by a thin film of oil after a few seconds, the

lubricator has been correctly adjusted�

The amount of oil going into the rock drill increases when turning

the valve counter clockwise, and it decreases when turning the

valve clockwise� Oil consumption is 2�5–6 ml/minute�

Note! Tighten the nut after regulation�

Note! To much oil will have negative effects on the operation

whilst to little will result in damage to parts as the temperature

rises during operation�

Operation

Involuntary start�

WARNING

Involuntary start of the machine may cause injury�

• Keep your hands away from the start and stop device until you

are ready to start the machine�

• Learn how the machine is switched off in the event of an emer

-

gency�

• Stop the machine immediately in all cases of power supply

interruption�

Drilling

Starting the rock drill

1� Open the main valve for compressed air�

2� Open the cock for the flushing water�

3� Adjust the feed control lever to give a suitable feed force for

collaring the hole�

4� Align the rock drill so that the working tool touches the desired

collaring point�

5� Move the throttle lever forward a little, which will start water

flushing, percussion and rotation�

6� Collar the hole with reduced feed force�

7� Move the throttle lever fully forward once the working tool has

gained a secure footing in the rock�

Adjust the feed force by means of the control lever so that the 8�

maximum penetration rate is obtained�

The start-and-stop device of Pusher Leg Rock Drill YT29A can

cause a risk of an unimtentional start� To reduce and avoid causing

the risk of unintentional start, the control valve og inlet hose must

be switched off while the rock drill is put aside for long time�

Note! Do not bend the working tool as this will increase wear of

the shank bushing and piston� Furthermore, it can also affect drill

-

ing efficiency and increase the risk of working tool breakage�

Stopping the rock drill

Pull the throttle lever backwards, which will stop percussion, rota-

tion and flushing water�

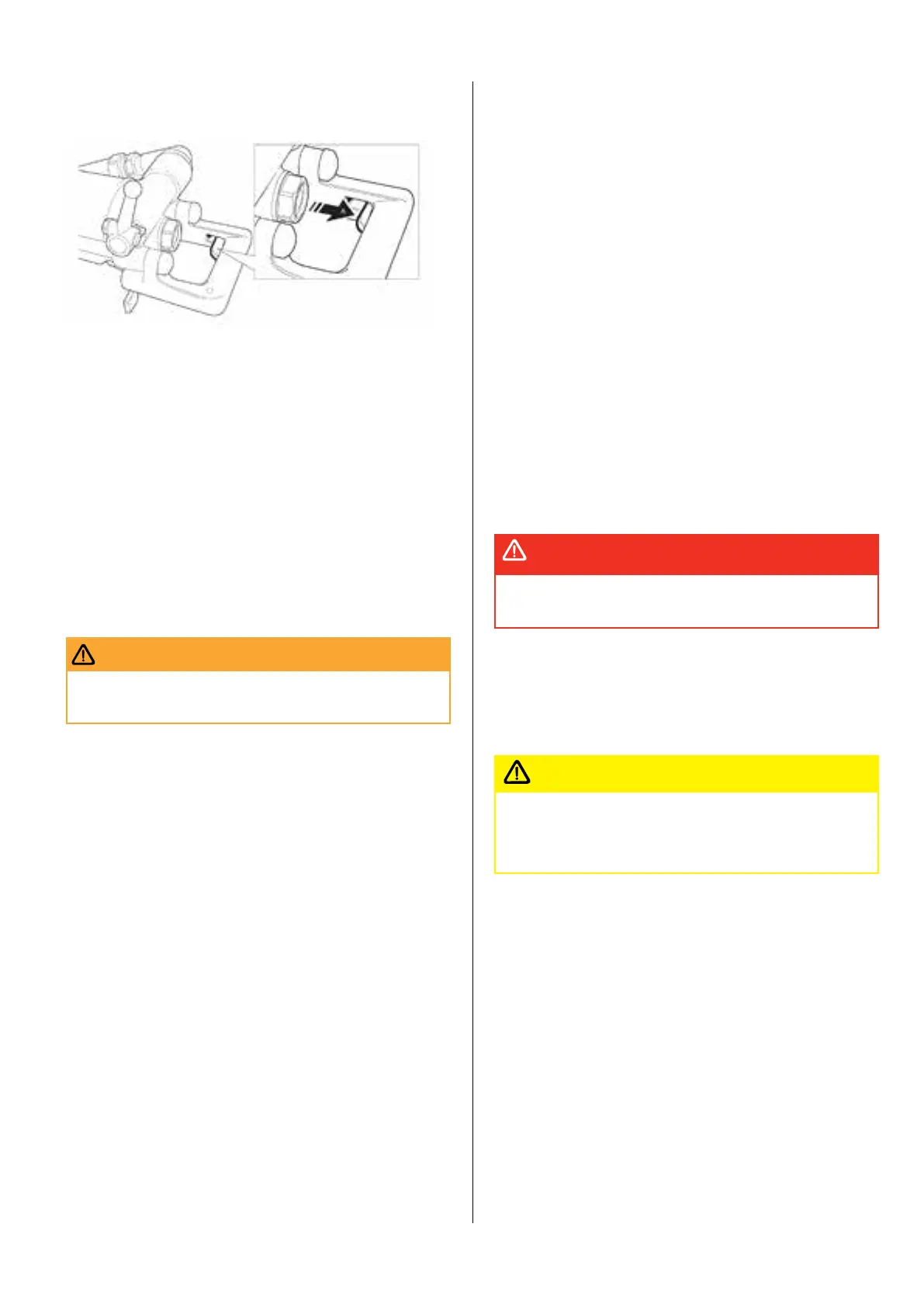

Re-positioning the pusher leg

1� Switch off the rock-drill percussion and flushing by means of

the throttle lever�

2� Press the trigger, whereupon the piston rod is pulled back into

the pusher-leg cylinder automatically�

3� Re-position the pusher leg�

4� Release the trigger, whereupon the piston rod will move out

-

wards again�

5� Move the throttle lever forward into the working position�

Note! The feed control lever does not need to be touched through

-

out this operation�

Blow-cleaning the drill hole

Whipping air hose�

DANGER

A compressed air hose that comes loose can lasharound and

cause personal injury or death

• Check that the compressed air hose and the connections are not

damaged�

• Check that all compressed air connections are properly attached�

Move to the side and cover your eyes before starting to blow-

clean the drill hole� When blow-cleaning, particles and dirty

flushing water can emerge at speed from the drill hole��

CAUTION

• Always wear impact resistant eye protection with side protection

to avoid injury�

• Make sure that no co-workers are in range when blow-cleaning�

If powerful blow-cleaning of the drill hole is required, turn the

throttle lever fully backwards beyond the stop position for extra

blowing, whereupon the rock drill stops� This can be done during

drilling� When the drill hole is clean, turn the throttle lever for

-

wards again to re-start the rock drill�

When you have finished drilling

Run the rock drill at medium speed when retracting the working

tool from the drilled hole�

Lay down the rock drill on a stone, wooden plank or similar ob

-

ject, so as to prevent drill cuttings and other foreign matter from

entering the chuck�

Turn off the water pressure before the air pressure� Run the rock

drill for a few seconds to clean out water and moisture after the

water has been shut off�

Loading...

Loading...