8.7.9 Water quality

8.7.9.1 Water quality control

When industrial water is used as chilled water, little furring may

occur; however, well water or river water, used as chilled water,

may cause much sediment, such as furring, sand, and so on.

Therefore, well water or river water must be filtered and softened

in softening water equipment before flowing into chilled water

system. If sand and clay settle in the evaporator, circulation of

chilled water may be blocked, and thus leading to freezing

accidents; if hardness of chilled water is too high, furring may

occur easily, and the devices may be corroded. Therefore, the

quality of chilled water should be analyzed before being used,

such as PH value, conductivity, concentration of chloride ion,

concentration of sulfide ion, and so on.

<50ppm

<50ppm

<30ppm

<200μV/cm(25℃)

<0.3ppm

<50ppm

<50ppm

8.7.9.2 Applicable standard of water quality for the unit

PH value

Total hardness

Conductivity

Sulfide ion

Chloride ion

Ammonia ion

Sulfate

Silicon

Iron content

Sodium ion

Calcium ion

No

No

No requirement

Table 8-9

7.5~9

h3: Water resistance of the longest water-loop distance,

includes:

pipe resistance, different valve’s resistance, flexible pipe

resistance,

pipe elbow and three-way resistance, two-way resistance or

three-way resistance, as well as filter resistance.

H4: the longest terminal resistance.

8.7.8.2 Installation the pump

a. The pump should be installed at the water inlet pipe, both of

which sides must mount the soft connectors for vibration-proof.

b. The backup pump for the system (recommended).

c. Units must with a main unit controls (Please see Fig. 8-22 for

the controls wiring diagram).

8.7.8 Selection and installation of the pump

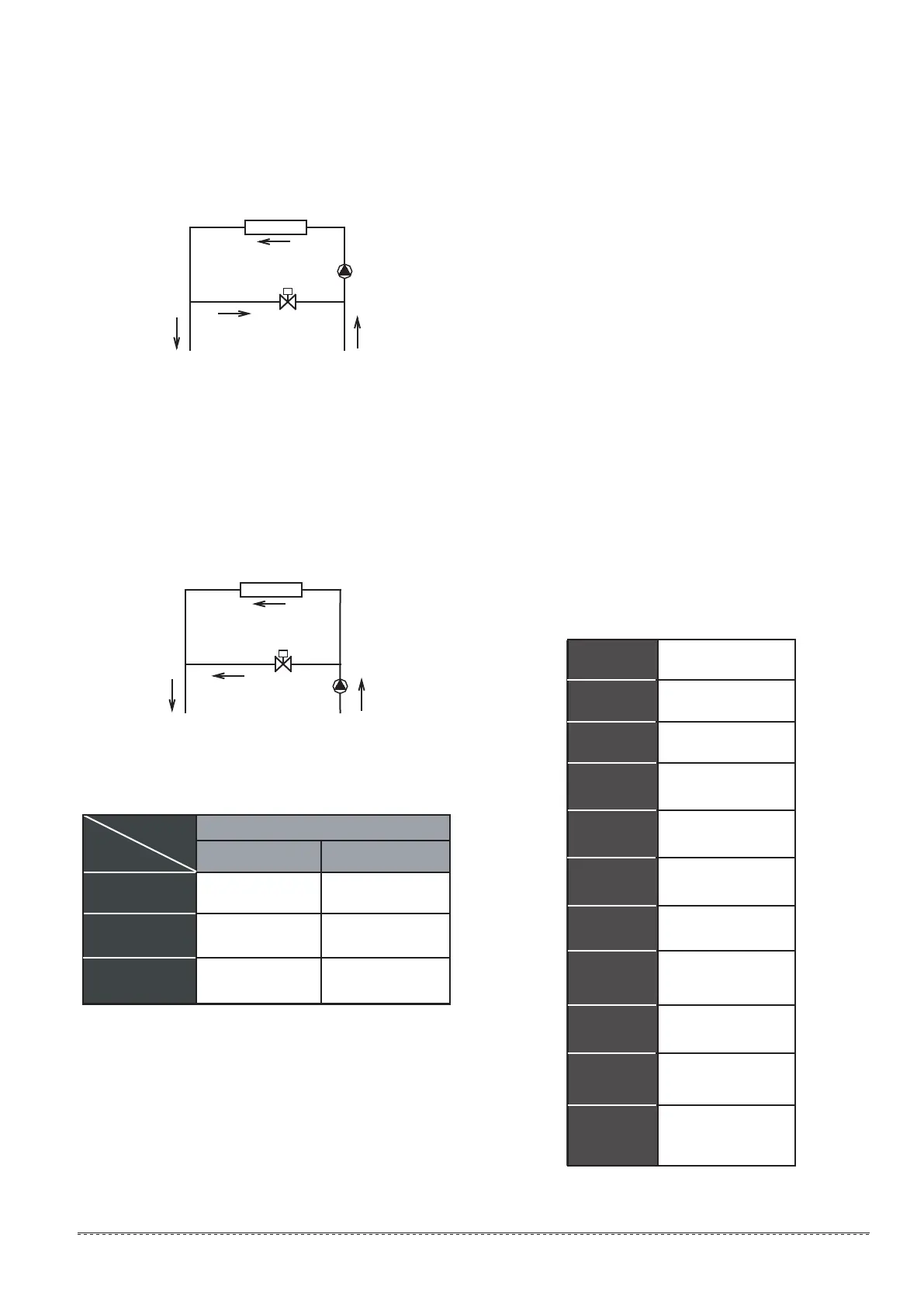

The minimum chilled water flow is shown in the table 8-8

If the system flow is less than the minimum unit flow rate,

the evaporator flow can be recirculated, as shown in the

diagram.

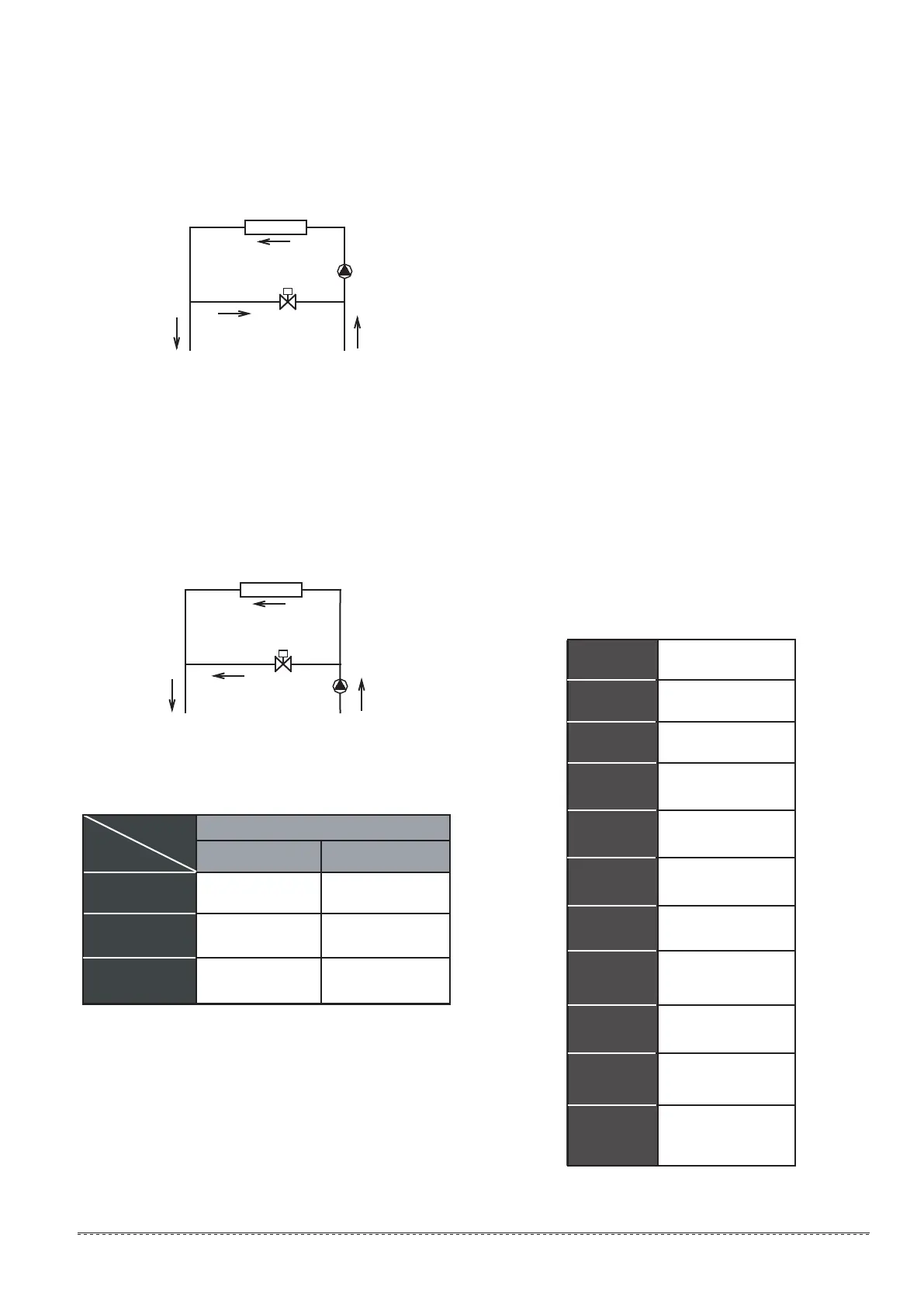

8.7.6 Maximum chilled water flow

The maximum chilled water flow is limited by the permitted

pressure drop in the evaporator. It is provided in the table 8-8

If the system flow is more than the maximum unit flow rate,

bypass the evaporator as shown in the diagram to obtain a lower

evaporator flow rate.

8.7.5 Minimum chilled water flow

For maximum chilled water flow rate

Evaporator

Recirculation

For minimum chilled water flow rate

Fig. 8-28

8.7.7 Minimum and Maximum water flow

Evaporator

Recirculation

Fig. 8-29

Table 8-8

Waterflow rate(m

3

/h)

Maximum

Minimum

Item

Model

13.0

ECH060N

8.0

6.4

ECH030N

3.8

16.5

ECH090N

13.5

8.7.8.1 Select the pump

a. Select the water-flow of the pump

The rated water-flow must no less than the unit rated water-flow;

in terms of multi-connect the units, that water-flow must no less

than total units’ rated water-flow.

b. Select the left of the pump.

H=h1+h2+h3+h4

H: The lift of the pump.

h1: Main unit water resistance.

h2: Pump water resistance.

40

Loading...

Loading...