16

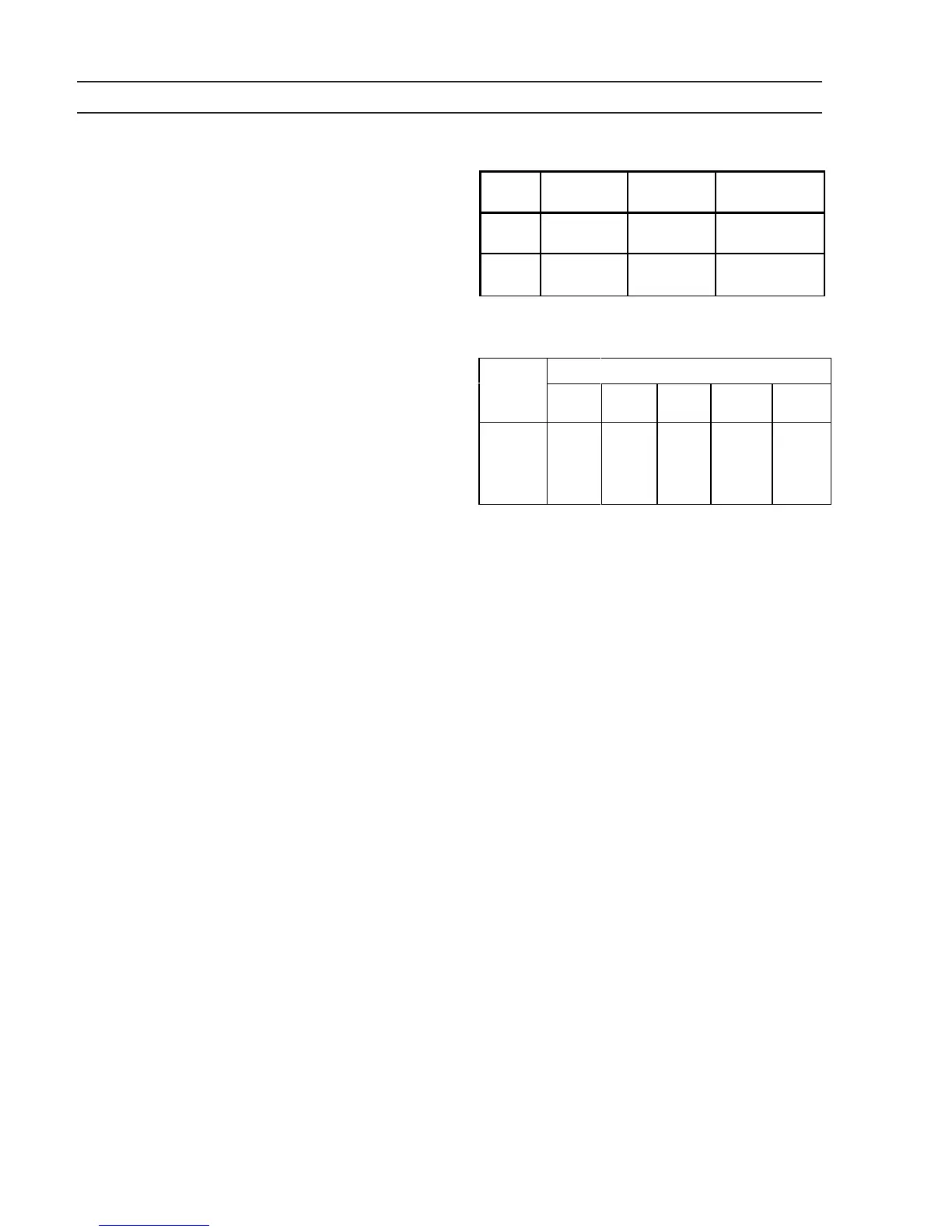

Table 2-2. Typical Output Connections

MIG Welding

(DCRP)

TIG Welding

(DCSP)

Stick Welding

(DCSP or DCRP)

Electrode

positive (+) negative (-)

positive (+) DCRP

negative (-) DCSP

Work negative (-) positive (+)

negative (-) DCRP

positive (+) DCSP

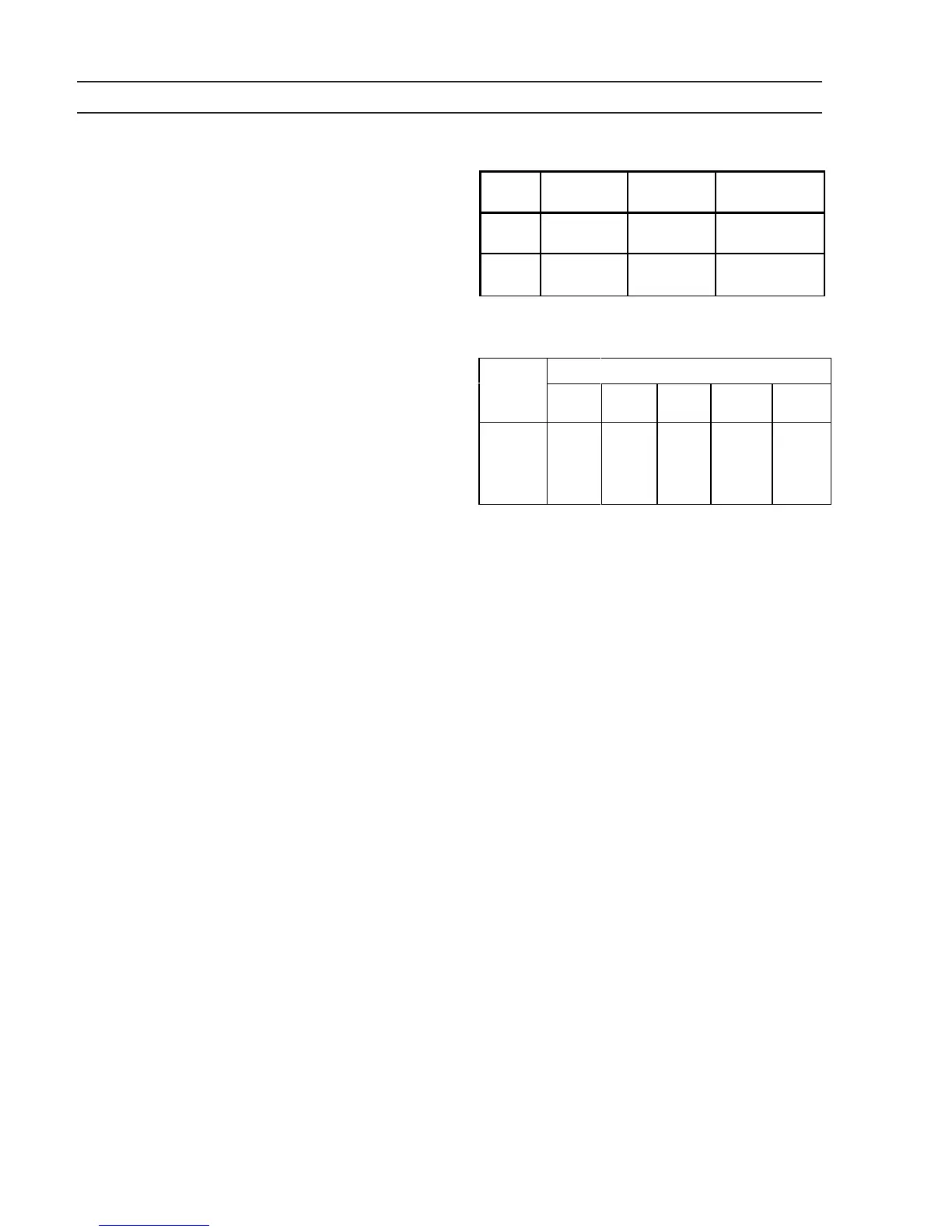

Table 2-3. Recommended Welding

Cable Sizes - AWG (mm

2

)

Welding

Current

Total Length (Feet) of Cable in Welding Circuit*

50

(13 m)

100

(25 m)

150

(38 m)

200

(51 m)

250

(64 m)

100

150

200

250

300

6 (16)**

4 (25)**

3 (30)**

2 (35)

1 (50)

4 (25)**

3 (30)**

1 (50)

1/0 (50)

2/0 (70)

3 (30)**

1 (50)

1/0 (50)

2/0 (70)

3/0 (95)

2 (35)

1/0 (50)

2/0 (70)

3/0 (95)

4/0 (120)

1 (50)

2/0 (70)

3/0 (95)

4/0 (120)

4/0 (120)

* Total cable length includes work and electrode cables. Cable size is based on direct

current, insulated copper conductors, 100% duty cycle, and a voltage drop of 4 or

less volts. The welding cable insulation must have a voltage rating that is high

enough to withstand the open circuit voltage of the machine.

** The supplied male output connectors will not accept anything smaller than #2 gauge

(35 mm ) cable.

as close together as possible to limit this resistance.

Make sure that the work cable (ground) is large enough,

kept as short as possible, properly insulated, securely

connected to the workpiece, and that all connections

are clean and tightly secured. If the work circuit includes

mechanical fixtures, ship structure, robot fixtures, etc.,

make sure that the circuit is secure and presents a low

resistance path to the flow of weld current. Also, the

power cable on a water-cooled torch is normally subject

to gradual deterioration and increasing resistance due

to corrosion which leads to the poor performance

described above. To assure good torch performance,

the water-cooled power cable should be replaced peri-

odically.

SECTION 2 INSTALLATION

Loading...

Loading...