Celebrating over 30 years of excellence in manufacturing ultrasonic cleaning

equipment, electropolishing equipment and associated chemistries

ESMA, Inc.

P. O. BOX 734 * SOUTH HOLLAND, IL 60473 * (800)-276-2466 * FAX (708)331-8919

Esma Inc.

PO Box 734 450 W. Taft Drive

South Holland, IL 60473

708-331-1855 800-276-2466 FAX 708-331-8919

Instructions for

Model E992 Passivation

Ultrasonic Washer

Introduction

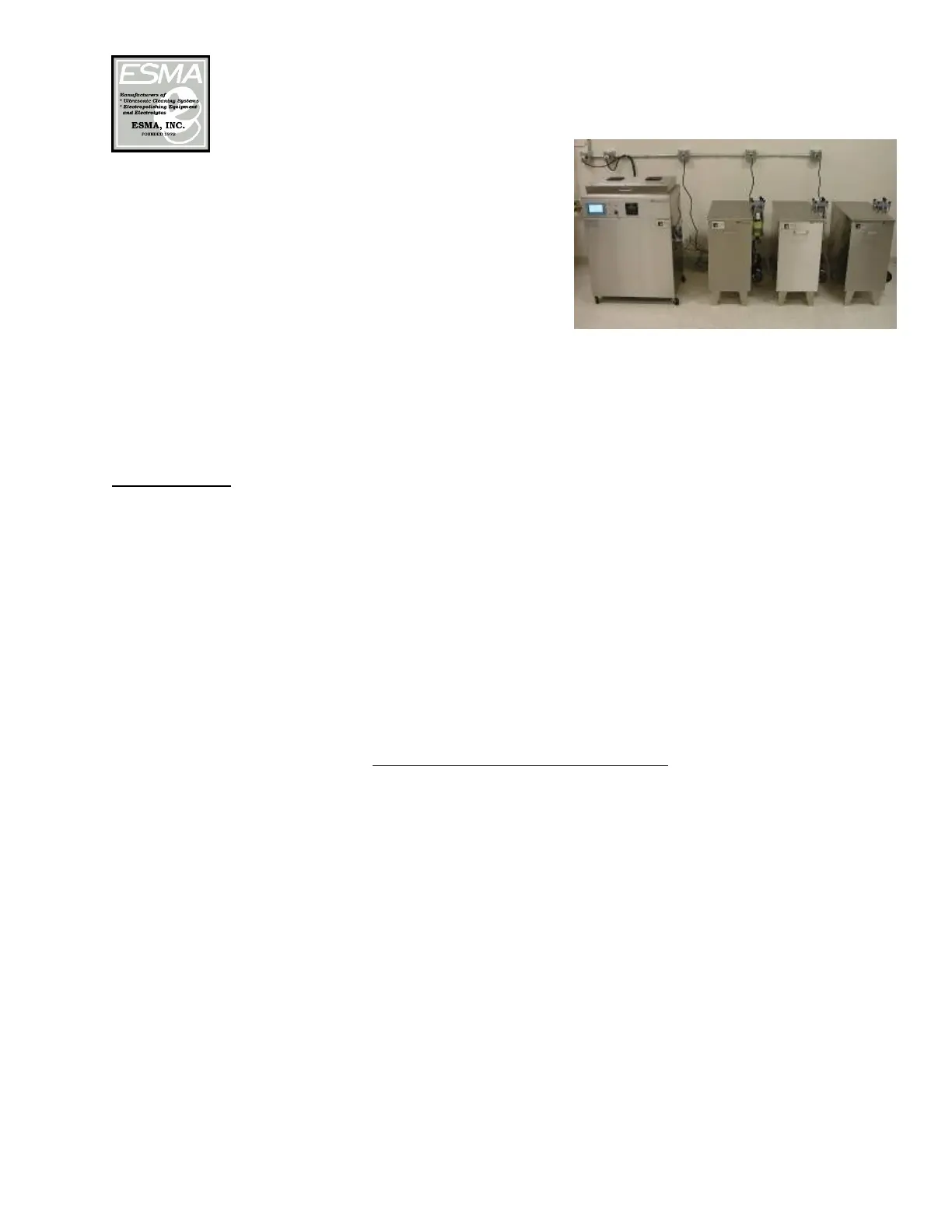

The Model E992 ultrasonic washer is equipped with three, 30 gallon heated storage

tanks (HST) for alkaline cleaning solution, citric acid or nitric acid solution and

rinse water. Pump filter systems are also incorporated into the HST’s. The

complete system also uses fresh DI water for a final rinse cycle.

The unit is housed in a 304 stainless steel console. The tank is manufactured from

SS 316 with 36 double potting transducers mounted on the bottom. The tank is

fitted with a SS hinged cover, which houses the fans and heaters for air drying.

Inside the console there are 2 Power Module boxes (generators) and the drain

pumps. The Power Modules contain the self-tuning modular circuit boards, high

velocity fans to cool the electronics, and RFI filters to eliminate any high

frequency interference. A control box is mounted on the rear of the console unit

and contains the programmable controller and other related components.

A Beijer HMI panel mount interface is included with the unit allowing monitoring

of the on-line operation and modifying of the program, as well as data collection of

the passivation process.

PLEASE READ THESE INSTRUCTIONS THOROUGHLY BEFORE

INSTALLATION AND OPERATION. CALL (800) 276-2466 IF YOU HAVE

ANY QUESTIONS.

Loading...

Loading...