MAINTENANCE

WARNING! Always unplug the pump before performing any maintenance work on

it.

- Clean the suction strainer and non-return valve regularly.

- Check pressure switch operation regularly (upper limit/lower limit).

- Protect the unit from frost during storage and operation.

- Inside the pressure tank is a pressure membrane and air tank where the pressure should

be approximately 1,3 bar checked when line pressure is 0. If air pressure does not stay in

the tank, the membrane is broken. Check membrane operation regularly (see chapter

”Operation”).

- If the pressure in the air tank is too low, increase it by unscrewing the plastic lid at the

end of the tank and pump air in the valve with a tyre filler.

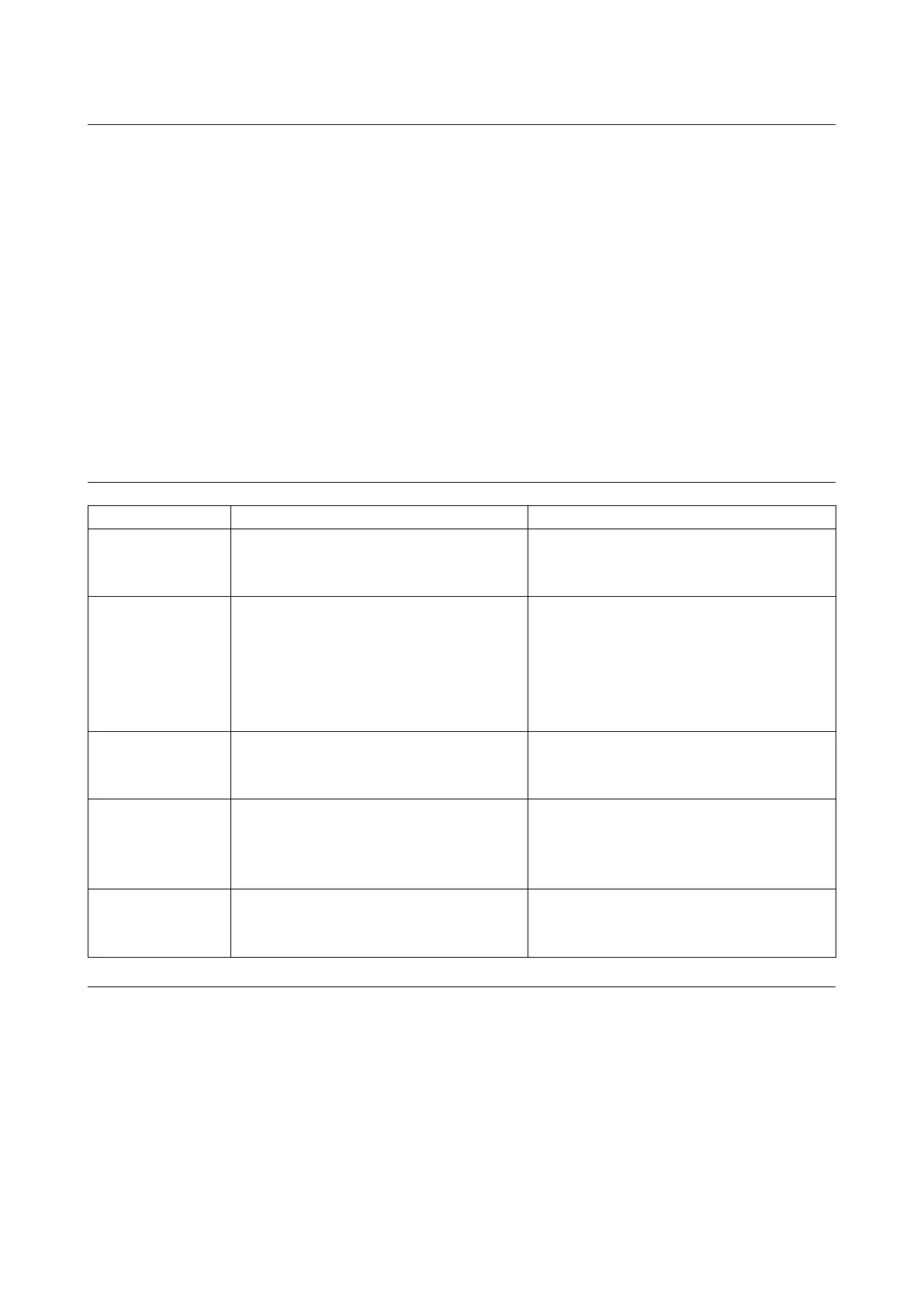

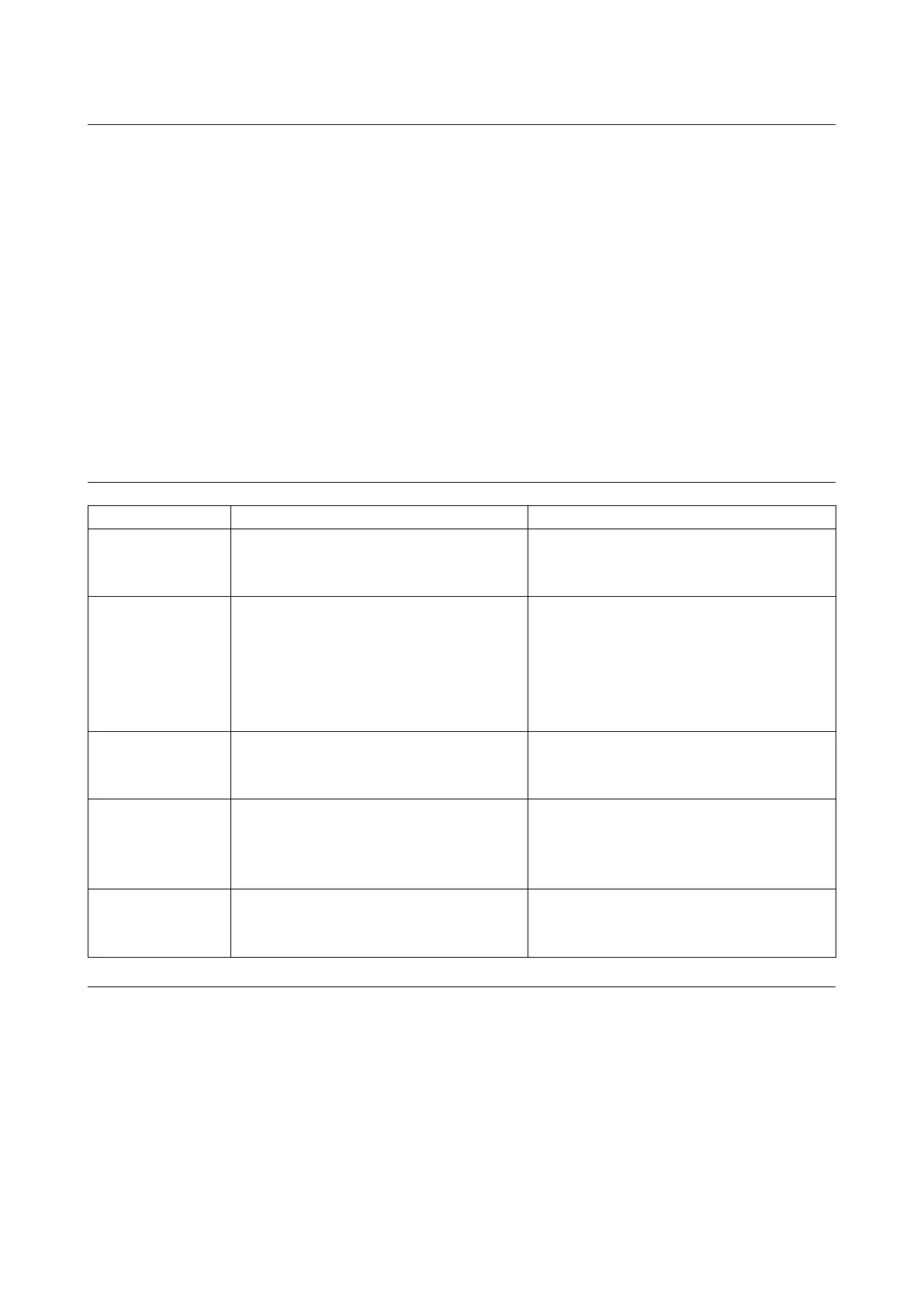

TROUBLESHOOTING

Motor does not

start.

Insufficient mains voltage.

- Blocked pump wheel.

Mains current fuse in off-state.

Check the voltage.

- Dismount and clean the pump.

Check the state of the fuse.

No suction in

the pump.

Suction valve is not in the water.

- No water in the pump.

- Air in the suction pipe.

- Suction valve leaks.

- Blocked suction valve.

- Too high suction height.

Sink the suction valve in the water.

- Fill the pump with water.

- Check the tightness of the air pipe.

- Clean the suction valve.

- Clean the suction valve.

- Check the suction height.

Pump switches

on at low water

Insufficient air pressure.

Increase air pressure (1,3 bar) by

pumping air in the valve.

ery.

- Too high suction height.

- Dirty suction housing.

- Harmful substance decreases

- Check the suction height.

- Clean the suction housing.

- Clean the pump and change worn

switch shuts

- Overloaded motor, foreign mat-

ter in the system causes friction.

- Dismount and clean the pump.

Prevent foreign matter from get-

10

Loading...

Loading...