BE SURE THE UNIT DISCONNECT IS IN THE “OFF” POSITION

AND THAT ALL ELECTRICAL POWER TO THE UNIT IS

TURNED OFF BEFORE CLEANING THE SYSTEM.

Remove any loose grass, leaves, papers, etc., from the area

around the condenser coil. These could reduce the air supply

through the coil and reduce the amount of cooling capacity.

3. Since the air conditioner is located outdoors, it is exposed to all

weather elements. Treat it with a good automobile paste wax

twice a year (in the spring and fall).

Check with your contractor if you have any questions regarding

the maintenance or operation of your unit.

INSTALLATION

A

. CODES

The installer SHALL comply with all local, state, and federal codes

and/or regulations pertaining to this type of equipment and its

installation. Such codes and/or regulations should take

precedence over any recommendations contained herein.

Installations SHALL be made in accordance with the National

Electrical Code, local codes, and recommendations made by the

National Board of Fire Underwriters.

B. UNIT SITE SELECTION

1. To eliminate noise from being transmitted into noise

sensitive areas, the unit should NOT be installed on walls

adjoining bedrooms, sleeping quarters, or adjacent to

windows.

5. R

eturn and supply grilles must be used when the return

and supply are not ducted. When a supply grille is used

in the installation, the louver spacing must be no greater

than 5/8 inch.

6. If the factory-installed filter is used on your installation,

access to the filter is made through the center panel on the

front of the unit.

IF A REMOTE FILTER IS USED, SUCH AS A FILTER GRILLE,

THE FACTORY-INSTALLED FILTER MUST BE REMOVED AND

DISCARDED.

D. DUCTWORK

1. Properly-sized duct systems are critical for satisfactory

operation of any air conditioning system. All ductwork

MUST be correctly sized for the design air flow requirement

of the equipment.

2. The recommended operation duct static is to deduct 0.07"

W.C. for any size of heater 5 kW to 20 kW on factory or

field-installed heaters.

3. Ductwork routed through wall cavities, as well as any duct

not in conditioned space, MUST be insulated. Supply

ducting routed through exterior walls MUST be insulated

with 1" insulation to the back of the unit.

4. Supply and return air ducts should be flush with the exterior

wall and sized to fit over the unit duct collars in order to

compress the collar air gasket.

5. If supply duct is flashed to the exterior of a building

c

onstructed with combustible material, the flashing MUST

be insulated in order to maintain the required clearances

to combustible materials. Required clearance is 1/4" for

the first three (3) feet of supply duct.

E. FILTERS

system or area to be conditioned, will prevent lengthy duct

1. One-inch disposable filters are supplied standard in each

runs and unnecessary thermal and air-pressure losses.

available as an option. The filter rack is adjustable to

for the first three (3) feet of supply duct.

adapted by bending the retaining brackets. Refer to the

SHALL be located at least 8" away from walls or other

obstructions for unrestricted airflow.

2.

filters.

If a filter grille is used in the installation, the filter should be

from any obstructions to prevent recirculation of condenser

air.

6.

Bottom of the unit SHALL be located at least 12" away from

the ground or other obstructions for unrestricted airflow.

FILTER MUST BE REMOVED.

panel located on the front of the unit and 28" from the

F. ELECTRICAL POWER

The installer MUST check available power to make certain it

matches the unit nameplate rating and that constant voltage can

be maintained to the unit. Unsatisfactory and unsafe performance

could otherwise result. The local power company should be

contacted about questions concerning power supply.

C. UNIT PREPARATION

1. The V Series model units have top rain flashing built onto

the unit. The bottom-mounting flange for all models is

shipped

se

p

a

r

a

t

e

l

y and

i

n p

l

a

c

e

. (

R

e

f

e

r to

“

S

e

c

t

i

on

J. U

n

i

t

I

n

s

t

a

ll

a

t

i

on

”

for

the

recommended use

of

the

bo

tt

o

m

flange.)

2. Electrical entrances are located on the right side, left side,

and back of all V

S

e

r

i

es

un

i

t

s

.

R

e

f

e

r to

“

Section H.

Electrical Hook-

up

”

for

d

e

t

a

il

s

.

3. Bend the lids of return and supply opening to form return

and supply air collars and install air gaskets.

4. The supply and return air ducts should be checked to be

sure they:

a. Match the openings on the unit to be installed.

b. Have the same distance between them vertically as

the openings on the unit to be installed.

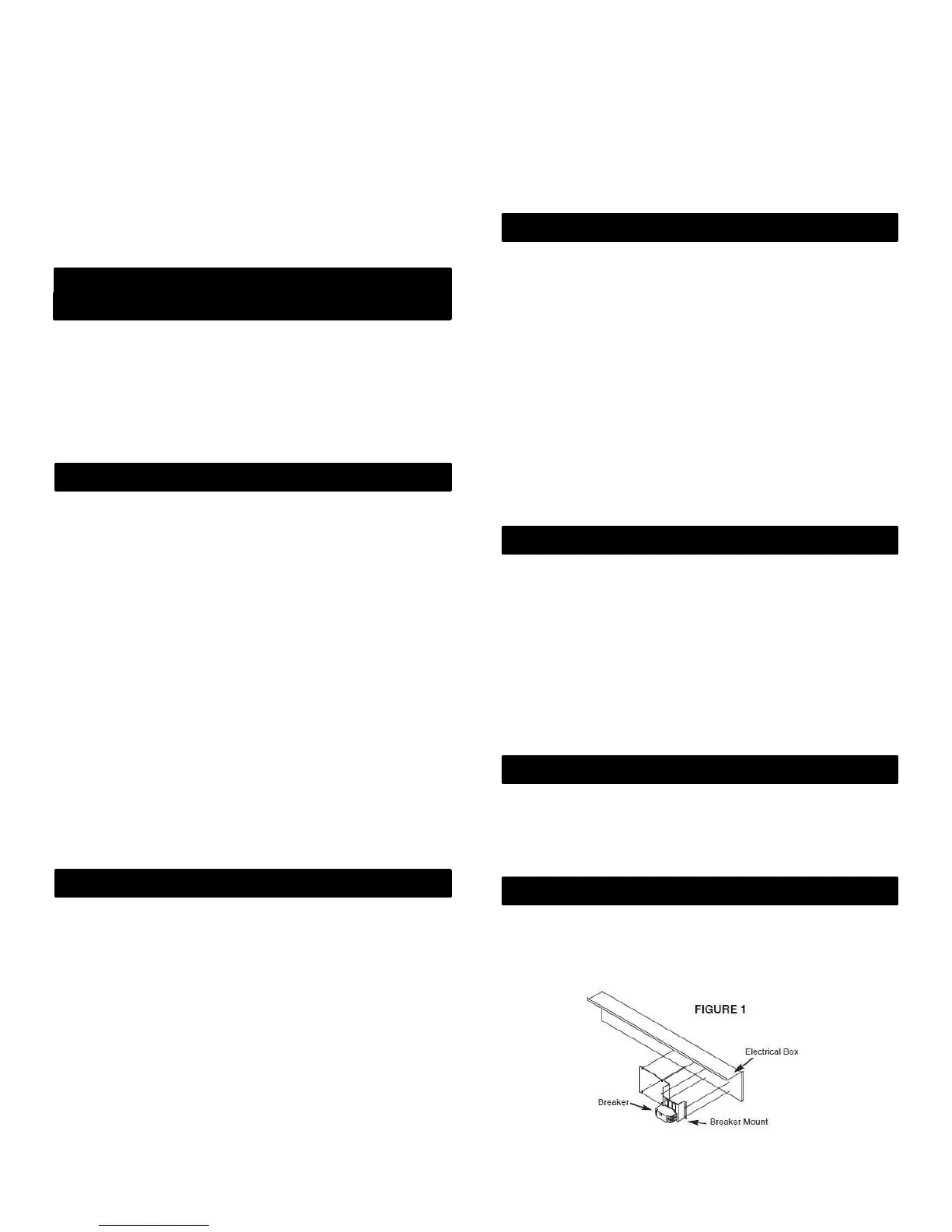

G. BREAKER/DISCONNECT ASSEMBLY

These units are standard equipped from the factory with a unit

disconnect. This is in the form of a circuit breaker (230V models)

or disconnect (460V models). If an optional electric heat kit is to be

installed, follow the instructions included with the heater assembly.

See Figure 1 for reference.

REV. 10/26/16

3

678628-W

Loading...

Loading...