5

Operating Instructions

Safety Contact Expansion ESM-TE3..

5. Setting time delay:

Set the desired time delay on the rotary knob and

seal the knob with the supplied sticker. (For xed

time variant ESM-TE3..-05S this step is not required

because a xed time delay of 0.5 seconds is set).

Attention: Tick marks should be regarded only as

a setting aid. Always make sure to measure the

time delay.

6. Starting the device:

Switch the operating voltage on.

Attention: If the Automatic start behavior is set

on the safety relay, the safety contacts will close

immediately.

If the Monitored manual start behavior is set, close

the start button to close the safety contacts.

The LEDs K1 and K2 on the safety relay and on the

ESM-TE3.. illuminate.

7. Activating safety function:

Open the emergency stop circuit by actuating the

connected safety switch. The safety contacts of the

safety relay open immediately; the safety contacts

of the ESM-TE3.. open after the time set on the

rotary knob elapses.

Attention: Measure the time delay.

8. Reactivating:

Close the emergency stop circuit. If Automatic start

is selected on the safety relay, the safety contacts

will close immediately.

If the Monitored manual start behavior is set, close

the start button on the safety relay to close the safe-

ty contacts of the safety relay and the ESM-TE3...

What to do in case of a fault?

Device does not switch on:

f Check the wiring of the ESM-TE3.. and the safety

relay by comparing it with the wiring diagrams (also

see operating instructions for the safety relay).

f Check the safety switch used on the safety relay

for correct function and adjustment.

f Check whether the emergency stop circuit of the

safety relay is closed.

f Check whether the start button on the safety relay

(with manual start) is closed.

f Check the operating voltage at A1 and A2 on the

safety relay and on the ESM-TE3...

f Is the feedback loop closed?

Device cannot be switched on again after an

emergency stop:

f Check whether the emergency stop circuit was

closed again.

f Was the start button opened before closing of the

emergency stop circuit (with manual start)?

f Is the feedback loop closed?

f Is the power supply present during the time

sequence?

If the fault persists, perform the steps listed under

Setup procedure.

If these steps do not remedy the fault either, return

the device to the manufacturer for examination.

Opening the device is impermissible and will

void the warranty.

Maintenance

The device must be checked once per month for

proper function and for signs of tampering and by-

passing of the safety function. Check the wiring of

the device and activate the emergency stop function.

Check the time delay.

The device is otherwise maintenance-free, provided

that it was installed properly.

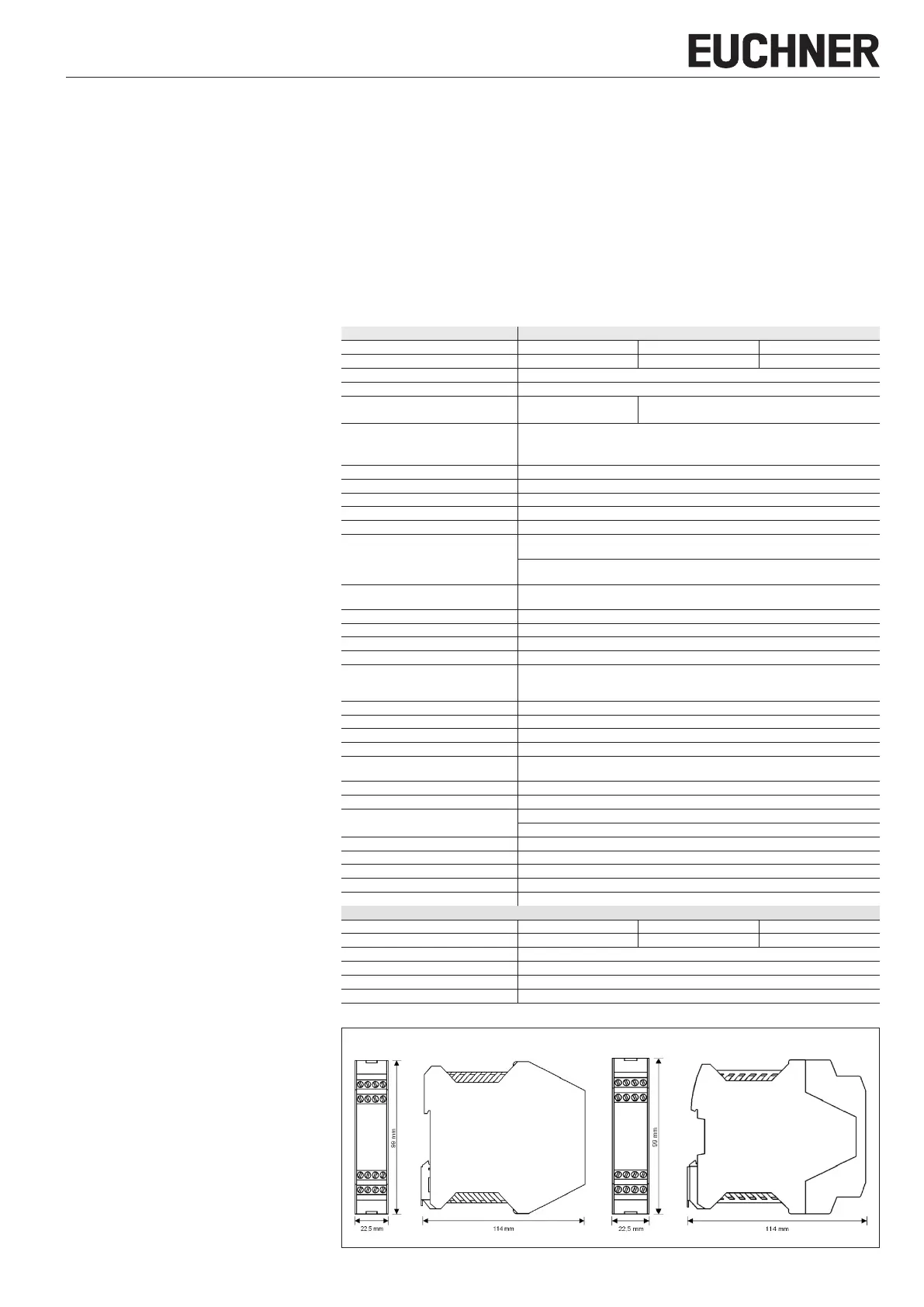

Fixed terminals

Plug-in terminals

Fig. 4: Dimension drawing for ESM-TE3..

Disposal

Pay attention to the applicable national regulations

and laws during disposal.

Declaration of conformity

The product complies with the requirements accord-

ing to Machinery Directive 2006/42/EC.

The EU declaration of conformity can be found at

www.euchner.com. Enter the order number of your

device in the search box. The document is available

under Downloads.

Service

If servicing is required, please contact:

EUCHNER GmbH + Co. KG

Kohlhammerstraße 16

70771 Leinfelden-Echterdingen

Germany

Service telephone:

+49 711 7597-500

E-mail:

support@euchner.de

Internet:

www.euchner.com

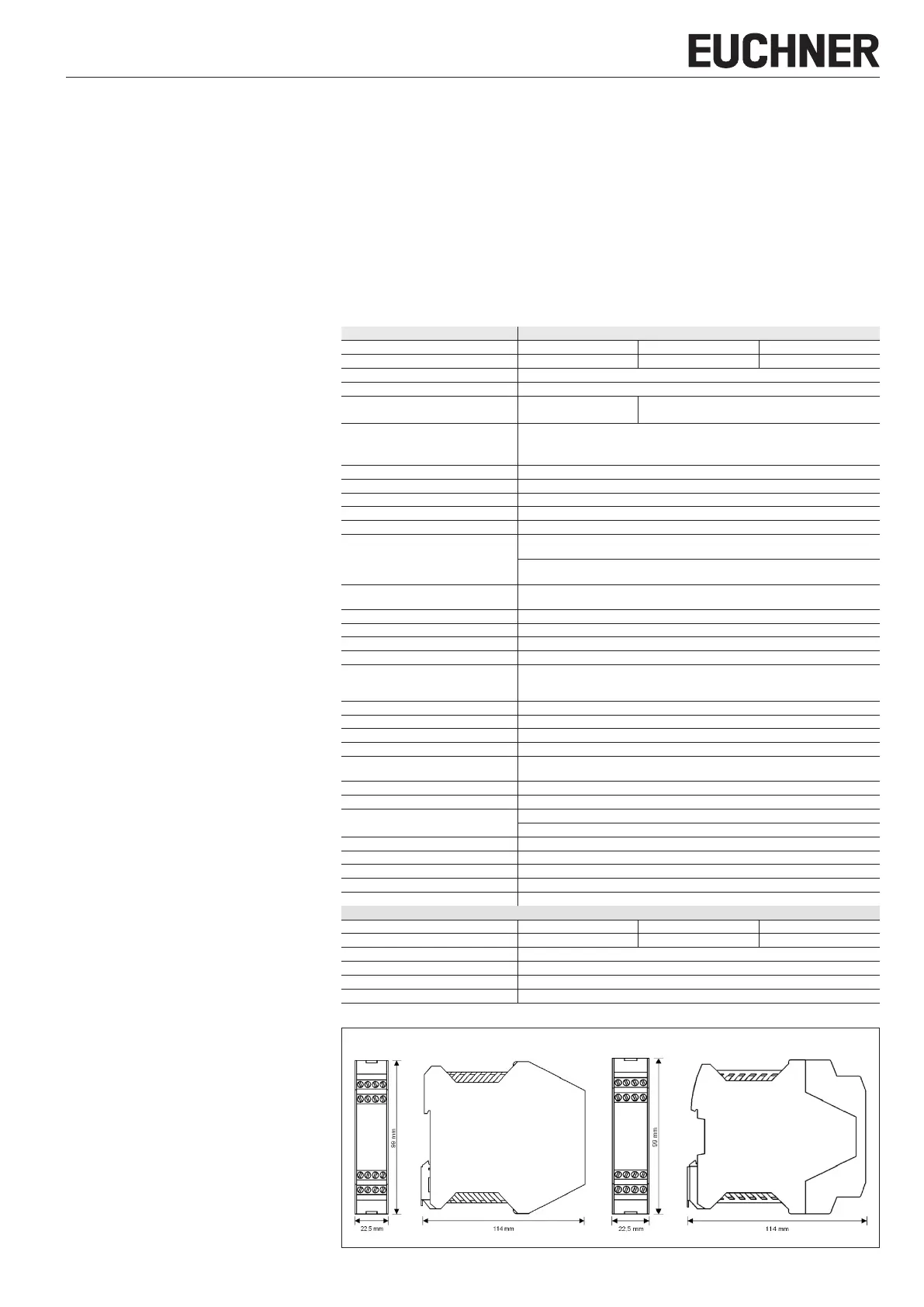

Technical data

Parameter Value

Version ESM-TE301 ESM-TE302 ESM-TE303

Operating voltage AC/DC 24 V AC 115 V AC 230 V

Rated supply frequency 50 - 60 Hz

Permissible deviation ± 10%

Power consumption DC 24 V AC 230 V

Approx. 1.5 W Approx. 4.0 VA

Time delay

ESM-TE3.. 1…30s, continuously adjustable

ESM-TE3..-05S 0.5s, xed

Control voltage at S11 DC 24 V

Control current S11…S14 Approx. 40 mA

Safety contacts 3 NO contacts

Monitoring contacts 1 NC contact (monitoring contact for safety relay)

Max. switching voltage AC 250 V

Safety contact breaking capacity

(17-18, 27-28, 37-38)

AC: 230 V, 1,500 VA, 6 A for ohm resistive load

230V, 4A for AC-15

DC: 24 V, 30 W, 1.25 A for ohm resistive load

24V, 2A, for DC-13

Max. cumulative current of all safety

contacts

10.5A

Minimum contact load 24 V, 20 mA

Contact fuses 6 A gG

Conductor cross-section 0.14 - 2.5 mm²

Tightening torque (min./max.) 0.5Nm/0.6Nm

Typ. switch-on delay/switch-off delay for

the normally open contacts upon demand

from the safety circuit

<60 ms / <50 ms

Max. length of control line 1,000 m with 0.75 mm²

Contact material AgNi

Mech. contact life Approx. 1 x 10

7

Test voltage 2.5 kV (control voltage/contacts)

Rated impulse withstand voltage, leakage

paths/air gaps

4 kV (DIN VDE 0110-1)

Rated insulation voltage 250 V

Degree of protection IP20

Temperature range DC24V: -15°C to +60°C

AC230V/115V/24V: -15°C up to +40°C

Installation altitude ≤2000m (above sea level)

Degree of contamination 2 (DIN VDE 0110-1)

Overvoltage category 3 (DIN VDE 0110-1)

Weight Approx. 230 g

Mounting Mounting rail acc. to ENIEC60715 TH35

Characteristics according to EN ISO 13849-1 for all variants of the series ESM-BA3

1)

Load (DC-13; 24V) ≤0.1A ≤1A ≤2A

n

op

≤400,000 cycles ≤73,000 cycles ≤17,000 cycles

T

10D

20 years

Category 3

PL d

PFH

D

1.03x10

-7

1/h

1) Additional data can be requested from the manufacturer for applications that deviate from these conditions.

Loading...

Loading...