776-3758 7 Rev. 07/21/14

SPRAY GUN

1. Submergethefrontendoftheguninsolventjustuntilthefluid

connection is covered.

2. Paintthathasbuiltuponthegunshouldberemovedusinga

bristlebrushandsolvent.

3. Neversubmergeallofthesprayguninsolventbecause:

• Thiswilldissolvethelubricantinthepackingsand

onwearsurfaces,causingthemtodryoutandresultingin

difficultoperationandfasterwear.

• Airpassagesinthegunwillbecomecloggedwithdirty

solvent.

4. Usingaragmoistenedwithsolvent,wipedowntheoutsideof

thegun.

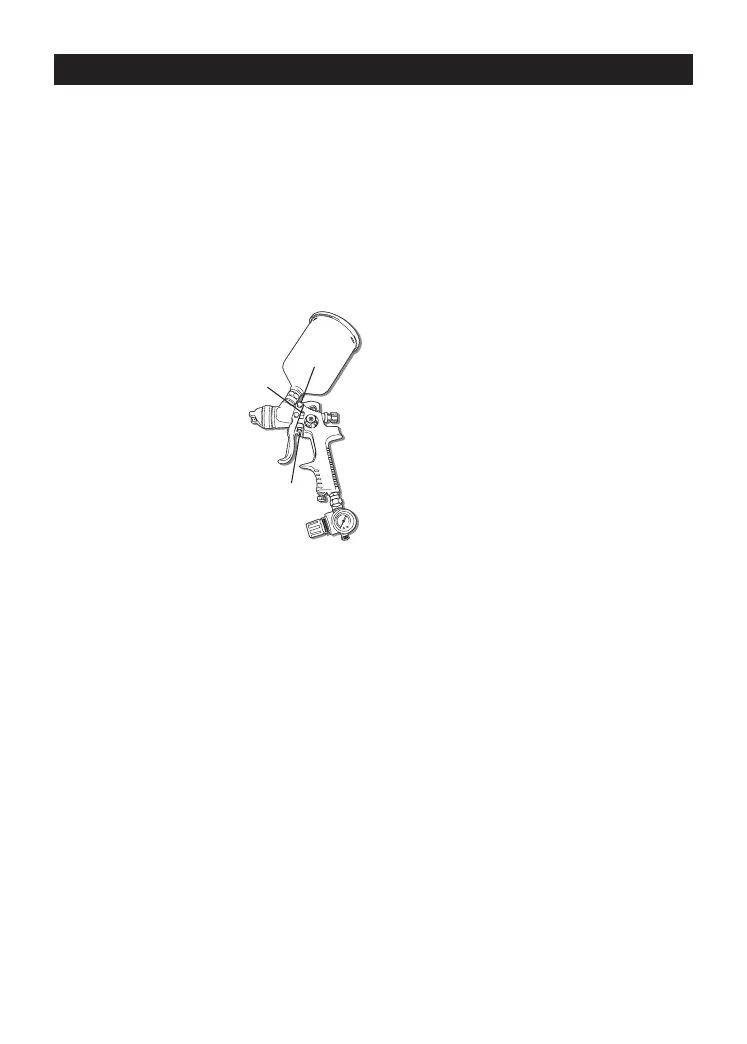

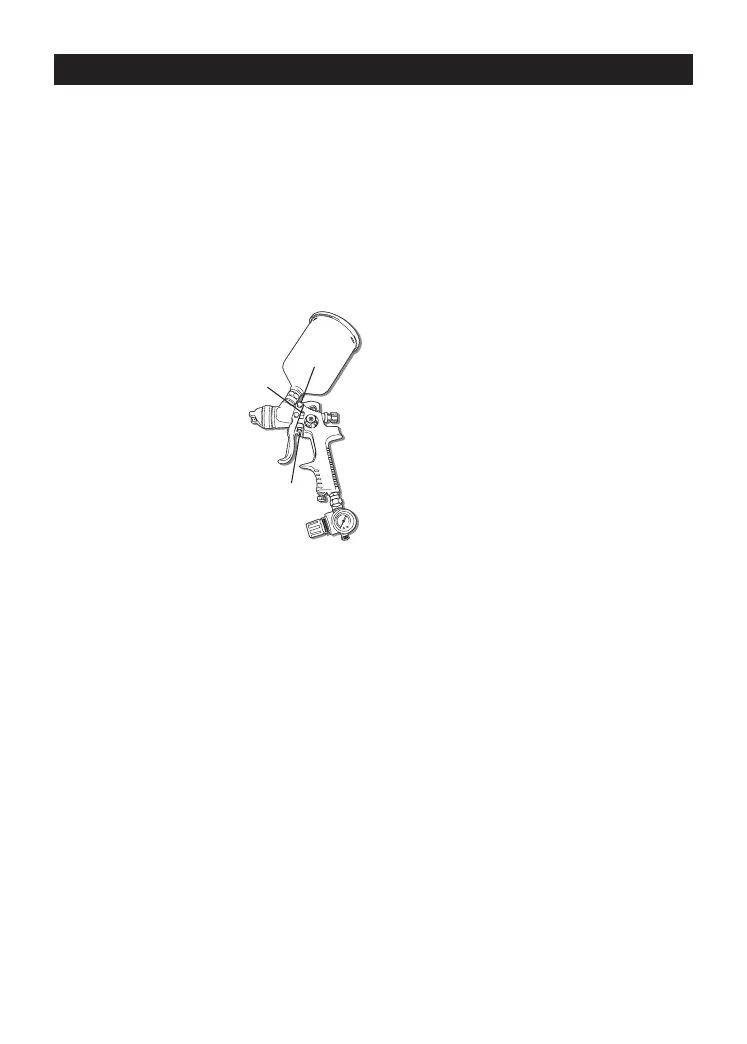

5. Oilgundaily.Useadropoflightweightmachineoilon:

A. fluidneedlepacking

B. airvalvepacking

C. trigger pivot point

SeeFig.1forLocationofAbovePoints.

6. NOTE:Donotsoakrubbero-rings

orsealsinpaintthinner.O-ringsand

sealscanbewipedcleanwithpaint

thinnerbutsoakingcancausethese

items to deteriorate over time.

7. Caution:Donotuselubricantswhich

containsilicone.Siliconemaycause

defectsinthefinishapplication.

NOTE: Alwaysshutoffairsupply,drain

hoseofairpressureanddisconnecttool

fromairsupplywhennotinuse,before

changingaccessoriesorwhenmaking

re pairs.

ClEANiNg ANd mAiNTENANCE

CAUTION

Toavoidcross-threading,allspraygunpartsshouldbescrewed

inhandtightinitially.Ifthepartscannoteasilybeturnedbyhand,

besureyouhavethecorrectparts,unscrew,realign,andtryagain.

NEVERuseexcessiveforceinmatchingparts.

AIR NOZZLE, FLUID NOZZLE, AIR VALVE ASSEMBLY

1. Allnozzlesandneedlesaremadetoexactstandards.They

shouldbehandledcarefully.

2. Tocleannozzles,immersetheminsolventuntilanydried

materialisdissolved,thenblowthemclean.

3. Donotusemetalorsharpinstrumenttoprobeanyoftheholes

inthenozzles.

4. Airflowshouldoccurbeforefluid-flowwhenthegunis

triggered.Itmaybenecessarytoadjustthefluidcontrolscrew

tomakesureairflowsbeforefluid.

5. Donotaltertheguninanyway.

GRAVITY FEED

Turnoffairsupply.Removecoverofcup.Emptythecupofmaterial.

Cleanthecupandcover.Turnonairsupplyandspraywithproper

cleaningsolvent.Repeatwithcleansolventifnecessary.Remove

solvent,disconnectgun,removeaircapandclean.Wipegunand

cupwithragdampenedwithsolvent.

C

A

B

Fig. 1

Loading...

Loading...