Installation

Step One: Mounting

This EverFlo pump is self-priming.

The pump should be located in an area that is dry and provides adequate ventilation.

The pump may be mounted in any position. However, if mounting the pump vertically the

pump head should be in the down position so that in the unlikely event of a leak, fluid will

not enter the motor.

Secure the rubber feet with #10 fasteners. DO NOT compress the feet, doing so will

reduce their ability to isolate vibration/noise.

Step Two: Plumbing

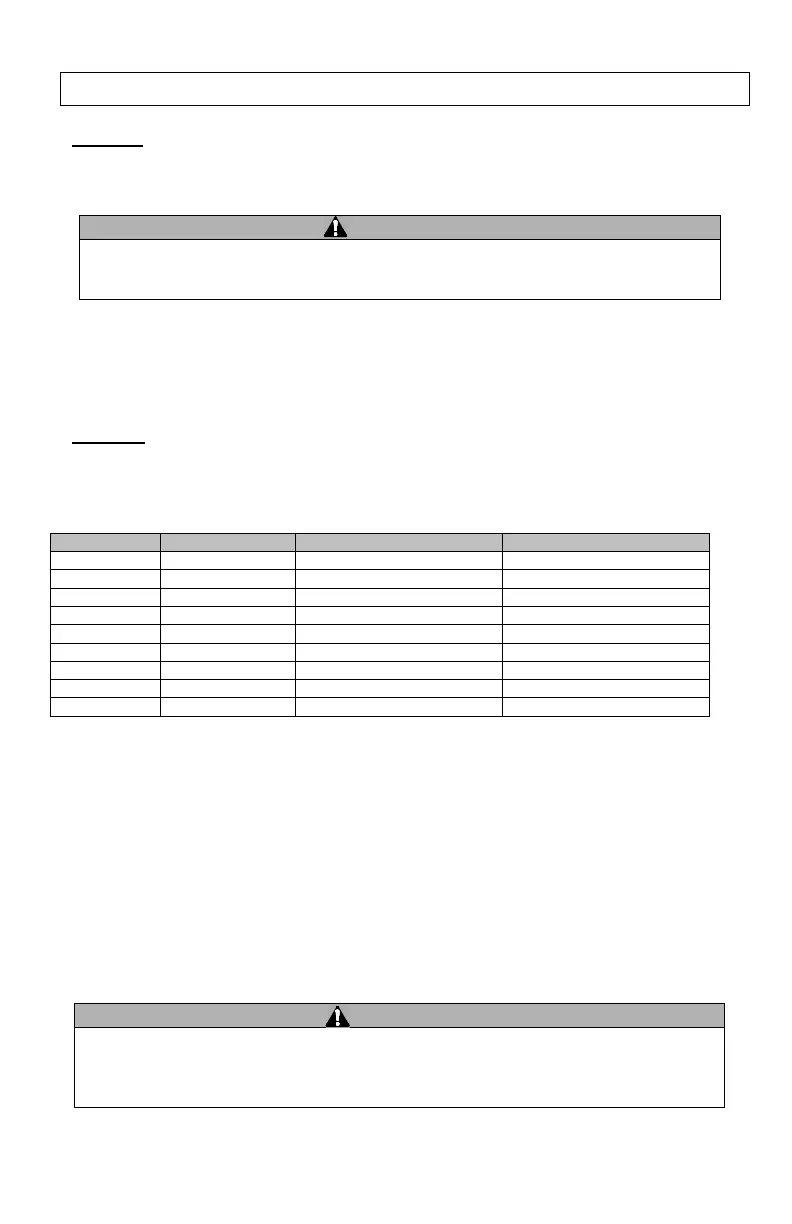

See table below for port size and recommended hose sizes. For pumps with female NPT

ports, use plastic male NPT (Tapered pipe thread) fittings to connect flexible high-pressure

tubing to the pump. For pumps with QA ports use EverFlo QA fittings.

3/8” (9.5mm) Inside diameter

3/8” (9.5mm) Inside diameter

3/8” (9.5mm) Inside diameter

3/8” (9.5mm) Inside diameter

3/8” (9.5mm) Inside diameter

3/8” (9.5mm) Inside diameter

1/2” (13mm) Inside diameter

1/2” (13mm) Inside diameter

1/2” (13mm) Inside diameter

1/2” (13mm) Inside diameter

1/2” (13mm) Inside diameter

1/2” (13mm) Inside diameter

1/2” (13mm) Inside diameter

1/2” (13mm) Inside diameter

1/2” (13mm) Inside diameter

1/2” (13mm) Inside diameter

1/2” (13mm) Inside diameter

1/2” (13mm) Inside diameter

NOTE: EverFlo does not recommend the use of metal fittings or rigid pipe to plumb the inlet/outlet

ports. Standard plastic threaded fittings are available by calling EverFlo Product Support

at 1-800-864-1649.

In some cases, the ports may require a suitable thread sealer applied sparingly. DO NOT

over-tighten, maximum torque is 45 in/lb [5 N-m].

Tubing should be compatible with the spraying fluid. At least 18” [450mm] length is

suggested to minimize stress on the fitting/ports and reduce noise. Allow for the shortest

possible tubing route and avoid sharp bends that may kink over time.

Installation of a 50-mesh strainer is recommended to prevent foreign debris from entering

the system. Failures due to foreign debris are not covered under the warranty.

NOTE: Restrictions on the inlet may cause a loss in performance. Inlet pressure must not exceed 30

psi [2.1 bar]

If a check valve is installed in the plumbing, it must have a cracking pressure of no more

than 2 psi [.14 bar].

DO NOT locate the motor near low temperature plastics or combustible material. The surface

temperature of the motor may exceed 250°F [121°C].

Sealers and Teflon tape may act as lubricant causing cracked housings or stripped threads due to

over tightening. Care should be used when applying sealers; it may enter the pump inhibiting

valve action, causing no prime or no shut-off. Failures due to foreign debris are not covered

under the warranty.

Loading...

Loading...