30

ENGLISH

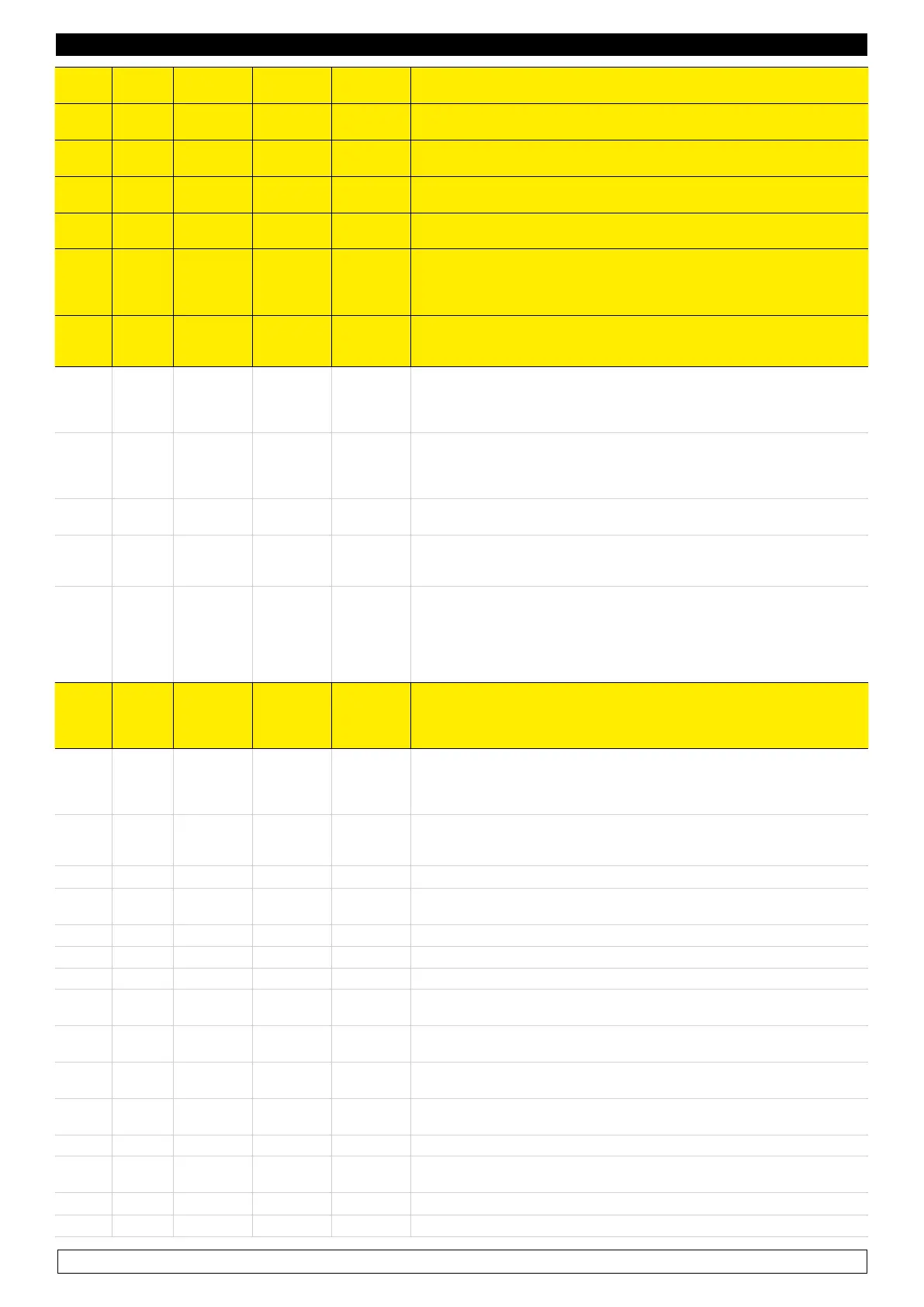

r9 -99.0 99.0

°C °F

(1)

-20.0

work set-point during blast chilling hard phase (cabinet temperature);

also see parameter r0

r10 -99.0 99.0

°C °F

(1)

2.0

work set-point during post blast chilling storage (cabinet temperature);

also see parameter r0

r11 -99.0 99.0

°C °F

(1)

-20.0

work set-point during post deep freezing storage (cabinet temperature);

also see parameter r0

r12 -99.0 99.0

°C °F

(1)

0.0

work set-point during pre-cooling (cabinet temperature); also see para-

meter r0

r13 -99.0 99.0

°C °F

(1)

15.0

end temperature of the temperature-controlled hard blast chilling phase

(temperature detected by the needle probe)

r14 10 100 % 60

duration of the time-controlled hard blast chilling phase (intended as a

percentage of the value established with parameter r1); also duration of

the time-controlled soft deep freezing phase (intended as a percentage of

the value established with parameter r2)

r15 -99.0 99.0 -C °F (1) 65.0

temperature below which the count of the maximum temperature-control-

led blast chilling and maximum temperature-controlled deep freezing is

started (temperature detected by the needle probe)

r16 0 2 - - - - 1

type of operating cycle that can be selected

0 = blast chilling and storage

1 = blast chilling and storage or deep freezing and storage

2 = deep freezing and storage

r17 0.0 99.0 -C °F (1) 5.0

“temperature detected by the needle probe - cabinet temperature” minimum diffe-

rence such to consider the rst phase of the test to verify correct insertion of the

needle probe completed successfully (consider the difference without sign) 0.0 =

the test will not be performed (neither rst or second phase)

r18 1 99 s 1

duration of the second phase of the test for verification of correct inser-

tion of the needle probe

r19 0 1 --- - 0

quick modication value during the “On” status before starting the operating cycle

0 = work set-point during blast chilling or during deep freezing 1 = blast chilling or

deep freezing end temperature

r20 0 1 - - - - 1

memorisation of the quick modification value during the “On” status be-

fore starting the operating cycle 0 = no (on start-up of the successive

same cycle, the values established with parameters r7 and r3 or those

establishes with r4 and r8 will be re-proposed) 1 = yes (on start-up of the

successive same cycle the rapidly modified values will be re-proposed

before starting the previous same cycle)

r21 0 1 ----- 0

modality the operating cycle is started time controller rather than time

controlled 0 = automatic (or through the test regarding correct insertion

of the needle probe) 1 = by hand (or pressing and releasing the BLAST

CHILLING or DEEP FREEZING key)

r22 0 1 ----- 0

modality to start pre-cooling 0 = automatic (or pressing the BLAST CHIL-

LING key 1 s) 1 = both automatic (or passing from the “stand-by” status

to the “on”, then switching on the device) and by hand (or pressing the

BLAST CHILLING key 1 s)

r23 0 50 S 2

duration of the buzzer activation to signal the verification test for the

correct insertion of the needle probe will not have been completed suc-

cessfully

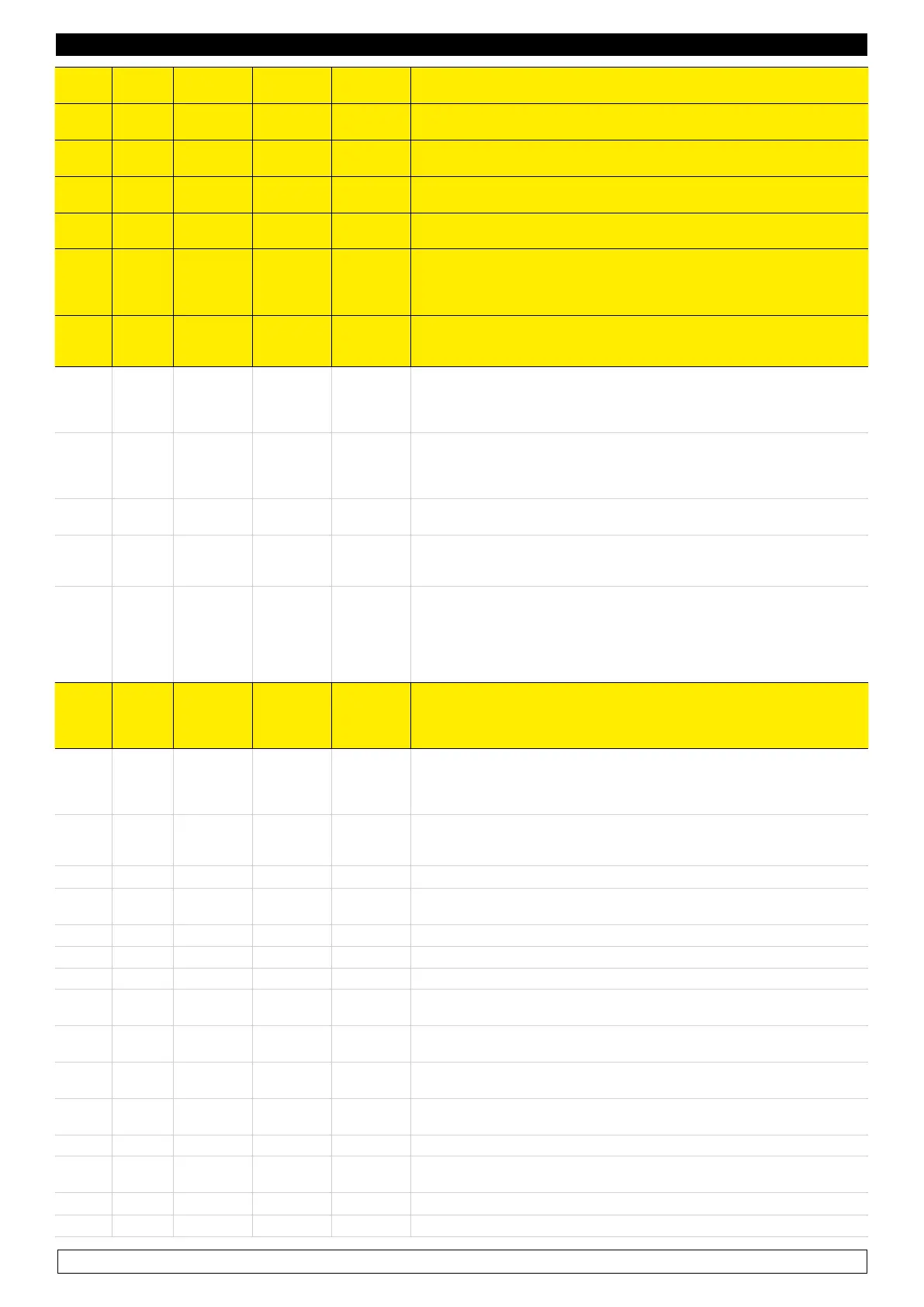

Par. Min. Max. Unit Default Compressor protections

CO 0 240 min 0

minimum time between restoring the power supply after a power cut, oc-

curring during an operating cycle and compressor switch-on

C1 0 240 min 5 minimum time between two consecutive compressor switch-ons (3)

C2 0 240 min 3

minimum time between compressor switch-off and successive switch-on (3)

C3 0 240 s 0 compressor switch-on minimum duration

C4 0 240 min 10

duration of compressor switch-off during the cabinet probe error (“Pr1”

code) that occurs during storage; see also parameter C5

C5 0 240 min 10

duration of compressor switch-on during the cabinet probe error (“Pr1”

code) that occurs during post blast chilling storage; also see parameter C4

C6 0 199.0

°C °F

(1)

80.0

condenser temperature above which the blocked overheated condenser

alarm is activated (“COH” code)

C7 0 199.0

°C °F

(1)

90.0

condenser temperature above which the blocked compressor alarm is ac-

tivated (“CSd” code)

C8 0 15 min 1 blocked compressor alarm delay (“CSd” code) (5)

C9 0 240 min 30

duration of compressor switch-on during the cabinet probe error (“Pr1”

code) that occurs during post deep freezing storage; also see parameter C4

Par. Min. Max. Unit Default Defrosting (6)

dO 0 99 h 0 defrosting interval (7) 0 = defrosting will never be activated at intervals

Loading...

Loading...