Do you have a question about the Farmi Forest FARMI 260 and is the answer not in the manual?

| Brand | Farmi Forest |

|---|---|

| Model | FARMI 260 |

| Category | Chipper |

| Language | English |

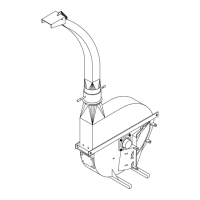

Identification of the primary parts of the chipper with numerical references.

Procedures and precautions for safely lifting the chipper.

Attaching the drawbar to the chipper for tractor connection.

Instructions for installing various feed units onto the chipper.

Procedures for adjusting the discharge pipe and its lid for optimal chip flow.

Step-by-step guide for safely starting the chipper operation.

Procedures for safely shutting down the chipper after use.

Guidelines for proper storage of the chipper to prevent damage.

Regular checks and tightening of fasteners for machine upkeep.

Guide to lubricating bearings for proper operation and longevity.

Instructions for lubricating PTO shaft components for smooth operation.

Checks on mounting bolts and knife-to-anvil clearance for machine upkeep.

Procedures for opening and removing the upper chamber for access.

Installing and tightening knives and anvils according to torque specifications.

Method for adjusting and checking clearance between knives and anvils.

Steps to remove both vertical and horizontal anvils for maintenance.

How to sharpen the vertical anvil to retain its original angle.

Loading...

Loading...