8

Flashes

/Beeps

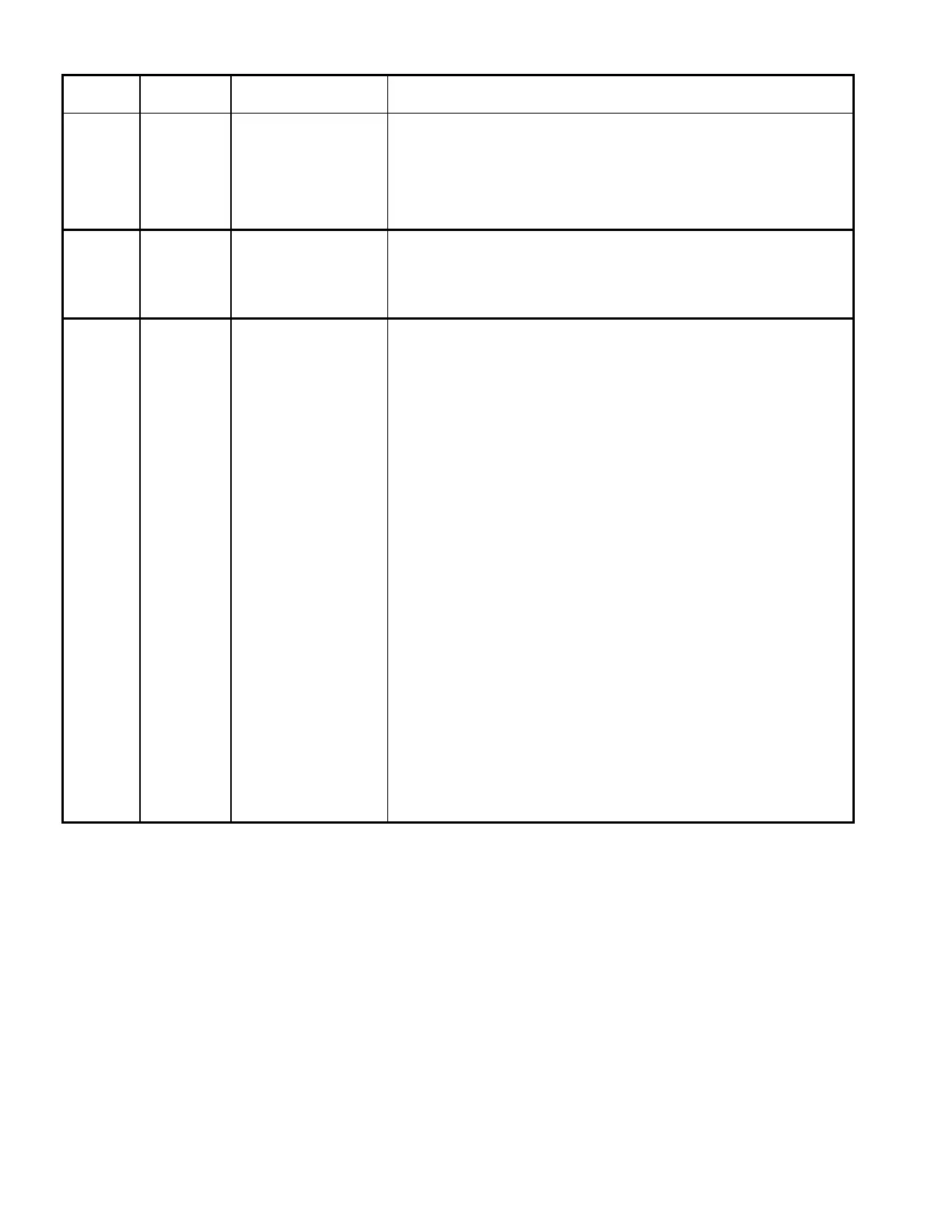

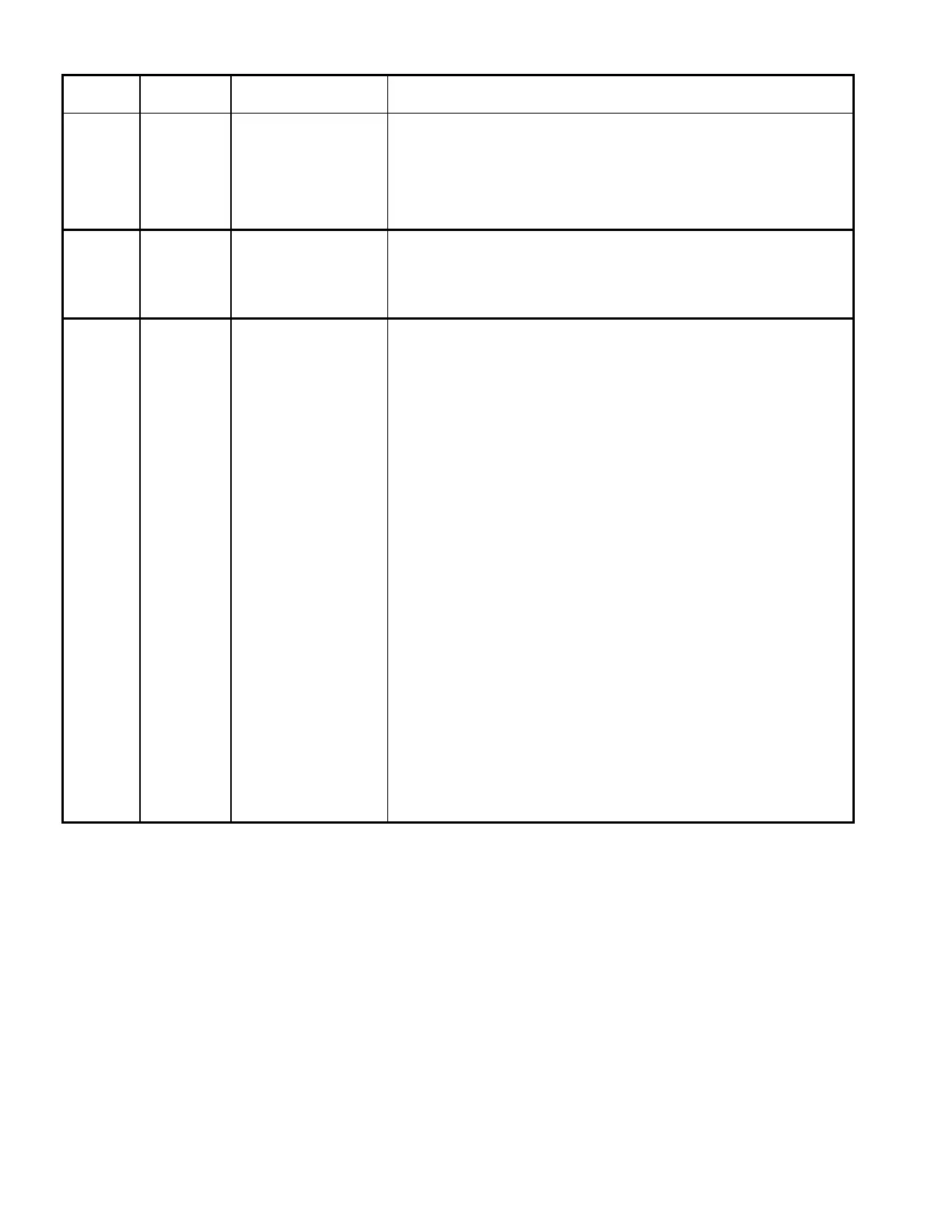

Condition Potential Causes Proposed Action

1

Under Load Low fuel level in the

storage tank

Or

Obstructions in Motor

Intake

Or

Calibrated with product

flow

Note: If Auto Restart Switch is set in the ON position once fuel is again above

the PMA end bell and the hook signal is reapplied the STP-SCI will

restart with out pushing the reset button.

1. Check fuel level in storage tank; schedule fuel delivery, when delivery is

complete and fuel level is above PMA end bell push reset button on STP-

SCI. Check for correct system operation. If fuel levels are within acceptable

range, the STP-SCI may need to be recalibrated if it was previously

calibrated with air in the lines or with product flow.

2

Low

Incoming

Voltage

Voltage fluctuations or

low input voltage

Note: STP-SCI will automatically restart when the voltage returns to

acceptable operating range.

1. Use AC voltmeter to verify incoming voltage is within the 208-240VAC

acceptable range. If voltage is not within this range, contact an electrician to

correct problem. If voltage is within acceptable range and condition is still

present after resetting, recalibrate controller per “Calibration” section.

3

Overload Short in wiring from STP-

SCI to PMA

Or

Incorrectly wired through

capacitor

Or

Foreign material in PMA

or rotor within motor is

locked up

1. Check and verify wiring is correct from STP-SCI to motor (shorts or

incorrectly wired capacitor). If condition is corrected, check for proper

operation. If operating correctly, do not continue with next step. If condition

is still present, continue to next step.

PMA Replacement/Inspection

2. Disconnect input voltage at load center, lock and tag out circuit breakers.

3. (See PMA Replacement Instructions P/N 400289002, included with New

PMA) Disengage the 3/4” securing bolt of the electrical connector and swing

out of the way. Remove two 9/16” bolts from extractable portion of the

manifold.

4. Pull extractable part of the pump.

Note: Pump Motor Assembly shell can be damaged by blows from hard

surfaces, use care in removing.

5. Remove black end cap from PMA and attempt to spin rotor with a 3/16”

Allen wrench to determine if there’s any binding. If rotor does not spin freely

and/or there is physical damage (note this on a warranty claim form for FE

Petro use), proceed with step 7. If no binding or physical damage to PMA,

reinstall extractable by following the previous steps in reverse order and

then continue to the next step.

Note: PMA can have a locked rotor during startups if it has been exposed to

a corrosive environment, such as a tank ballasted in water.

6. Turn on power to the STP-SCI unit and verify correct system operation. If

condition is corrected, do not continue to next step. If condition is still

present, remove the extractable by repeating steps 2 through 4 and then

continue to next step.

7. Remove four 5/16” cap screws that connect the PMA with a ¼” Allen wrench

and remove the PMA from the motor discharge head.

Note: Prior to mounting a new PMA, check lead assembly (wires inside the

extractable portion to PMA) for shorted wires and proper alignment,

which may have caused the condition.

8. Replace with new PMA.

Note: Pump motor shell can be damaged by blows from hard surfaces, use

care in replacing.

9. Re-install extractable and secure by following reverse order of disassembly.

10. Turn on power to the STP-SCI unit and verify correct system operation.

Loading...

Loading...