After 2 minutes if the low pressure switch remains

open, the control will shut down the compressor and

enter a soft lockout. The compressor will not be

energized until the low pressure switch closes and the

anti-short cycle time delay expires. If the low pressure

switch opens 2–4 times in 1 hour, the unit will enter a

hard lock out and need to be reset.

•

BROWNOUT/SURGE/POWER INTERRUPTION

PROTECTION— The brownout protection in the UPM

board will shut down the compressor if the incoming

power falls below 18 VAC. The compressor will remain

off till the voltage goes above 18 VAC and the anti

short cycle timer (300 seconds) times out. The unit will

not go into a hard lockout.

•

MALFUNCTION OUTPUT—Alarm output is Normally

Open (NO) dry contact. If 24 VAC output is needed R

must be wired to the ALR-COM terminal; 24VAC will be

available on the ALR-OUT terminal when the unit is in

alarm condition. If pulse is selected the alarm output

will be pulsed. The fault output will depend on the dip

switch setting for “ALARM”. If it set to “CONST’, a

constant signal will be produced to indicate a fault has

occurred and the unit requires inspection to determine

the type of fault. If it is set to “PULSE”, a pulse signal is

produced and a fault code is detected by a remote

d

evice indicating the fault. See L.E.D. Fault Indication

below for blink code explanations. The remote device

must have a malfunction detection capability when the

UPM board is set to “PULSE”.

•

TEST DIP SWITCH—

A test dip switch is provided to

reduce all time delay settings to 10 seconds during

troubleshooting or verification of unit operation. Note

that operation of the unit while in test mode can lead

to accelerated wear and premature failure of the unit.

The “TEST” switch must be set back to “NO” for normal

operation.

•

FREEZE SENSOR—The freeze sensor input is active all

the time, if a freeze option is not selected the freeze

terminals will need a jumper. There are 2 configurable

freeze points, 30°F & 15°F. The unit will enter a soft lock

out until the temperature climbs above the set point

and the anti-short cycle time delay has expired. The

freeze sensor will shut the compressor output down

after 90 seconds of water flow loss and report a freeze

condition. It is recommended to have a flow switch to

prevent the unit from running if water flow is lost.

NOTE: If unit is employing a fresh water system (no anti-

freeze protection), it is extremely important to have the

“Freeze” jumper R42 resistor set to 30°F in order to shut

down the unit at the appropriate leaving water

temperature and protect your heat pump from freezing if a

freeze sensor is included.

•

L.E.D. FAULT INDICATION—Two L.E.D. indicators

are provided:

• Green: Power L.E.D. indicates 18—30 VAC present at

the board.

• Red: Fault indicator with blink codes as follows:

- One blink—High pressure lockout

- Two blinks—Low pressure lockout

- Three blinks—Freeze sensor lockout

- Four blinks—Condensate overflow

- Five blinks—Brownout

•

INTELLIGENT RESET—If a fault condition is initiated,

the 5 minute delay on break time period is initiated

and the unit will restart after these delays expire.

During this period the fault LED will indicate the cause

of the fault. If the fault condition still exists or occurs 2

or 4 times (depending on 2 or 4 setting for Lockout dip

switch) before 60 minutes, the unit will go into a hard

lockout and requires a manual lockout reset. A single

condensate overflow fault will cause the unit to go into

a hard lockout immediately, and will require a manual

lockout reset.

•

LOCKOUT RESET—A hard lockout can be reset by

turning the unit thermostat off and then back on when

the “RESET” dip switch is set to “Y” or by shutting off

unit power at the circuit breaker when the “RESET” dip

switch is set to “R”.

970-292 Revised 5-12

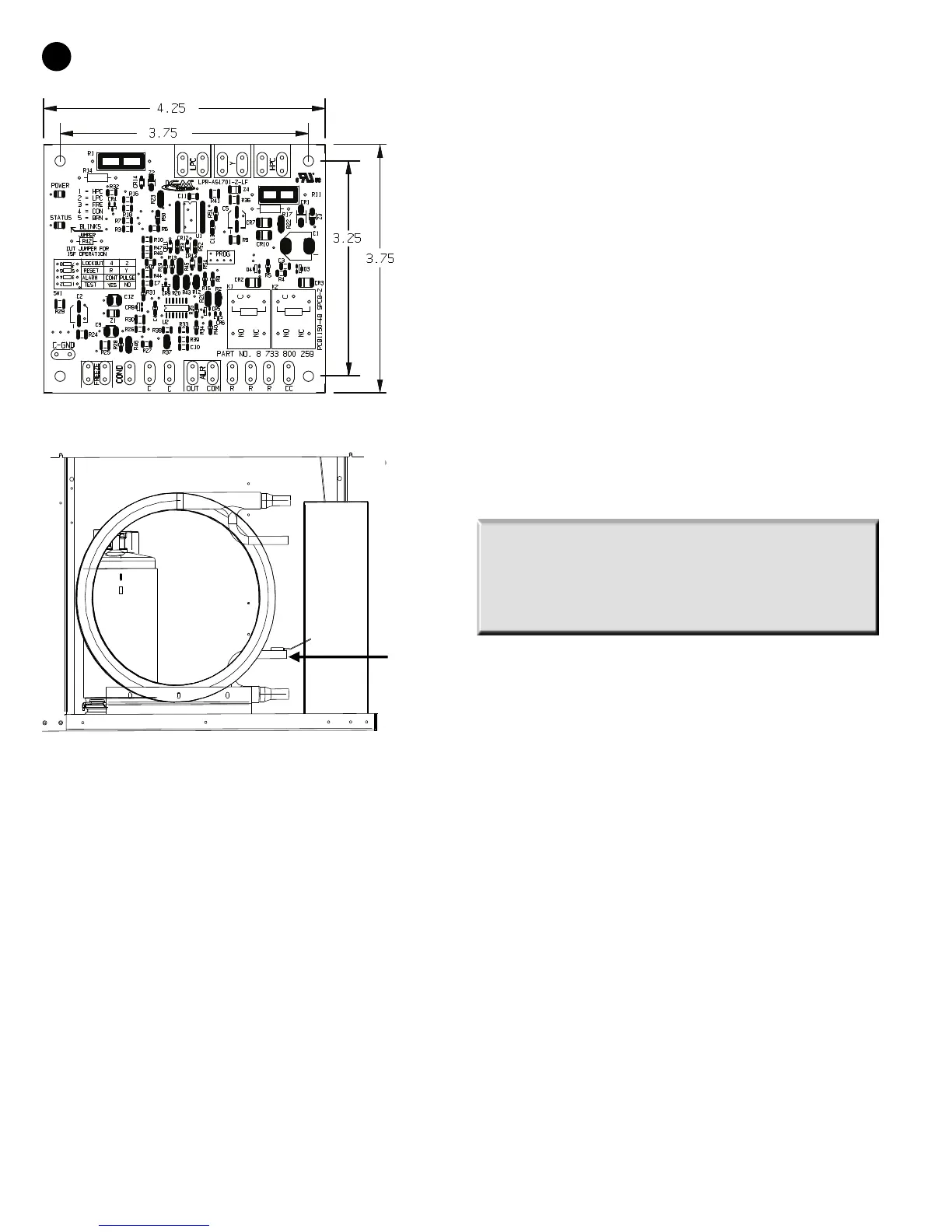

Freeze Protection Sensor

6

AP SERIES

Loading...

Loading...