page 2

PRESSURE SWITCH SENSING TUBE INSTALLATION

1. Attach the

1

⁄4" tubing connector to the pressure tube on the SWG Venter.

(See Figure 3)

2. Connect the supplied

1

⁄4" aluminum tubing to the tubing

connector. Route the tubing to the CK- 61 junction box and

connect the tubing to the pressure switch. When routing the

tubing, avoid kinking the tubing by bending the tubing

too sharply.

3. For remote mounted CK-61 junction box, use a

1

⁄4" OD

copper, aluminum or plastic tubing and route the tubing to

avoid contact with any heat source.

Refer to the SWG Venter installation instructions for setting

system air ow.

SEE THE APPLIANCE MANUFACTURER’S INSTRUCTIONS FOR THE SPECIFIC LOCATION.

IF THE APPLIANCE MANUFACTURER DOES NOT SPECIFY A LOCATION, REFER TO FIGURE 5.

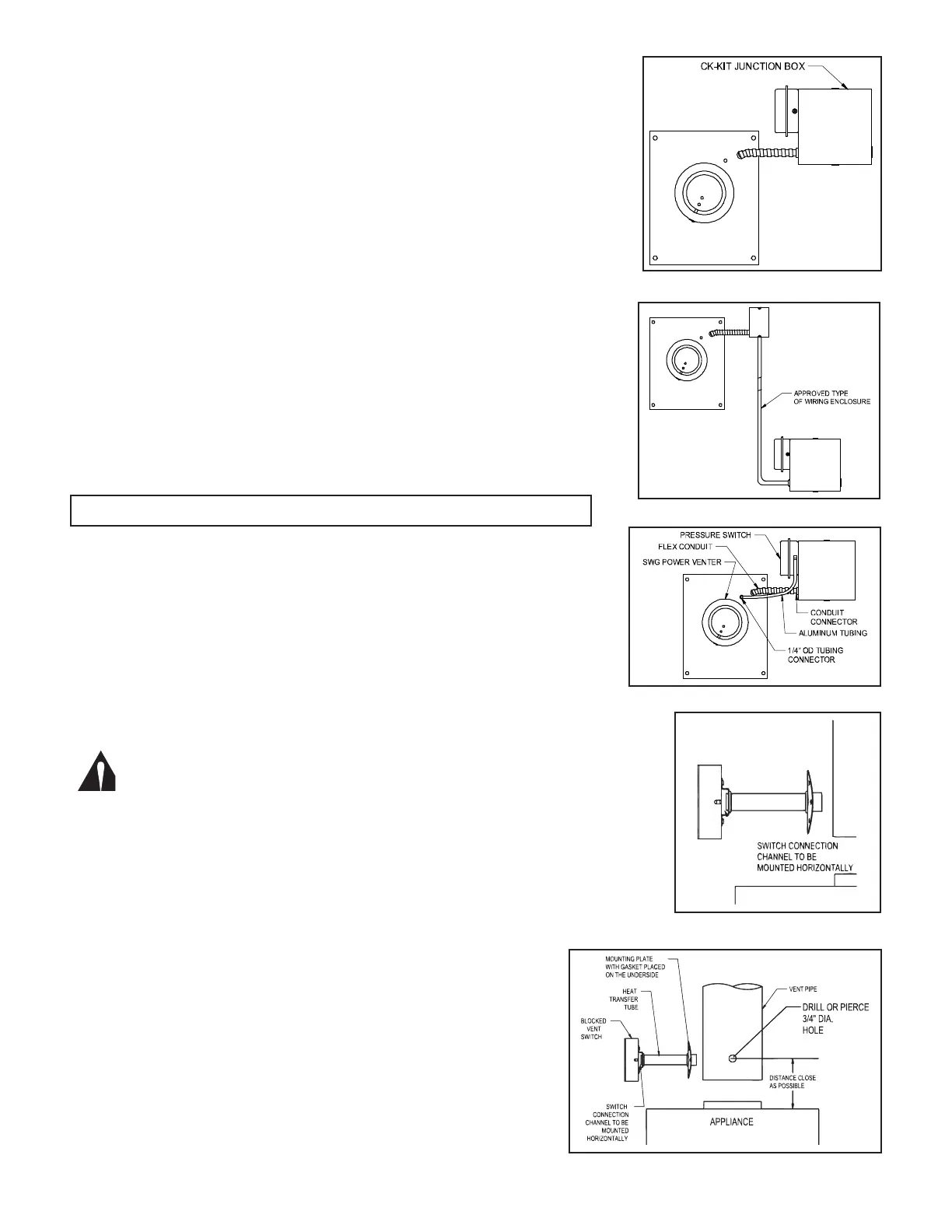

Figure 1

Figure 2

Figure 3

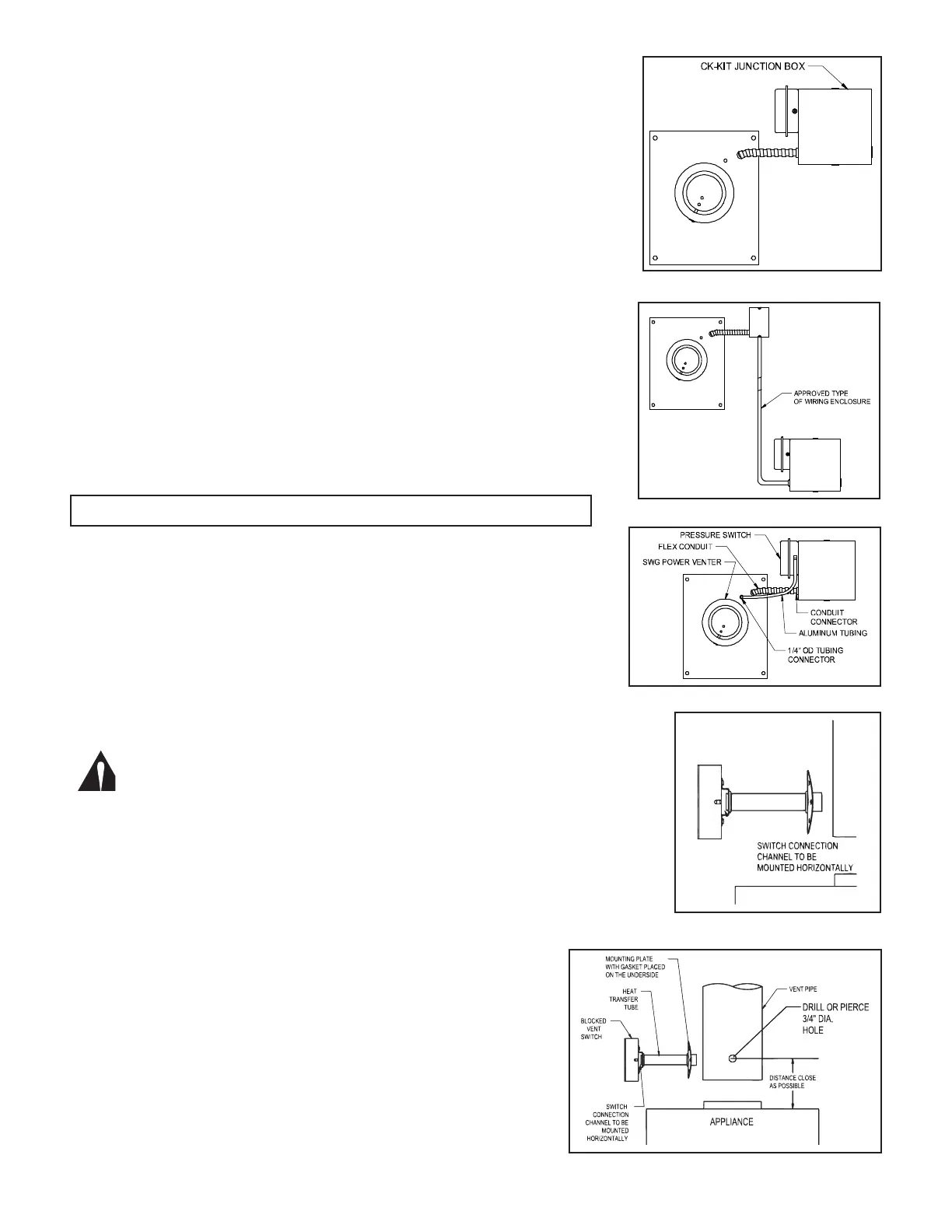

Figure 4

Figure 5

INSTALLATION

MOUNTING JUNCTION BOX

The junction box can be mounted at the venter or remotely mounted away

from the venter. (See Figure 1 & Figure 2)

1. Remove one of the knockouts from the side of the junction box where

the pressure switch is mounted. Install the exible conduit connector

onto the CK-61 junction box and secure with fastening nut. If remote

mounting the CK-61 junction box, mount the exible conduit connector

onto a 2” x 4” installer supplied junction box.

2. Fasten the exible conduit from the SWG Venter into the conduit

connector. Mount the CK-61 junction box or installer supplied junction

box onto the wall or oor joist without straining the exible conduit.

Fasten the CK- 61 junction box through the four dimpled locations on

the base of the box. (See Figure 3)

OIL FIRED SECONDARY SAFETY SWITCH (WMO-1)

Installation of a SECONDARY SAFETY SWITCH (WMO-1) is recommended

for detecting ue gas spillage from a blocked ue system and/or

inadequate draft.

MOUNTING IN THE VENT PIPE

1. Drill or pierce a clean hole (about

3

⁄4” diameter) in the vent pipe near

the appliance outlet. (See Figure 5)

2. The heat transfer tube must have the ber gasket installed against the

mounting plate before attaching the unit to the vent pipe.

3. Insert the heat transfer tube with gasket into the

3

⁄4” diameter hole

placed in the vent pipe during step 1.

4. Secure the assembly to the vent pipe with a minimum of 4 sheet

metal screws. The channel must be mounted horizontally, unless

speci ed di erently by the appliance manufacturer. (See Figure 5)

CAUTION: Disconnect electrical power supply to the appliance when wiring the

blocked vent switch.

WARNING: Switch connection channel must be mounted horizontally,

unless speci ed di erently by the appliance manufacturer.

Loading...

Loading...