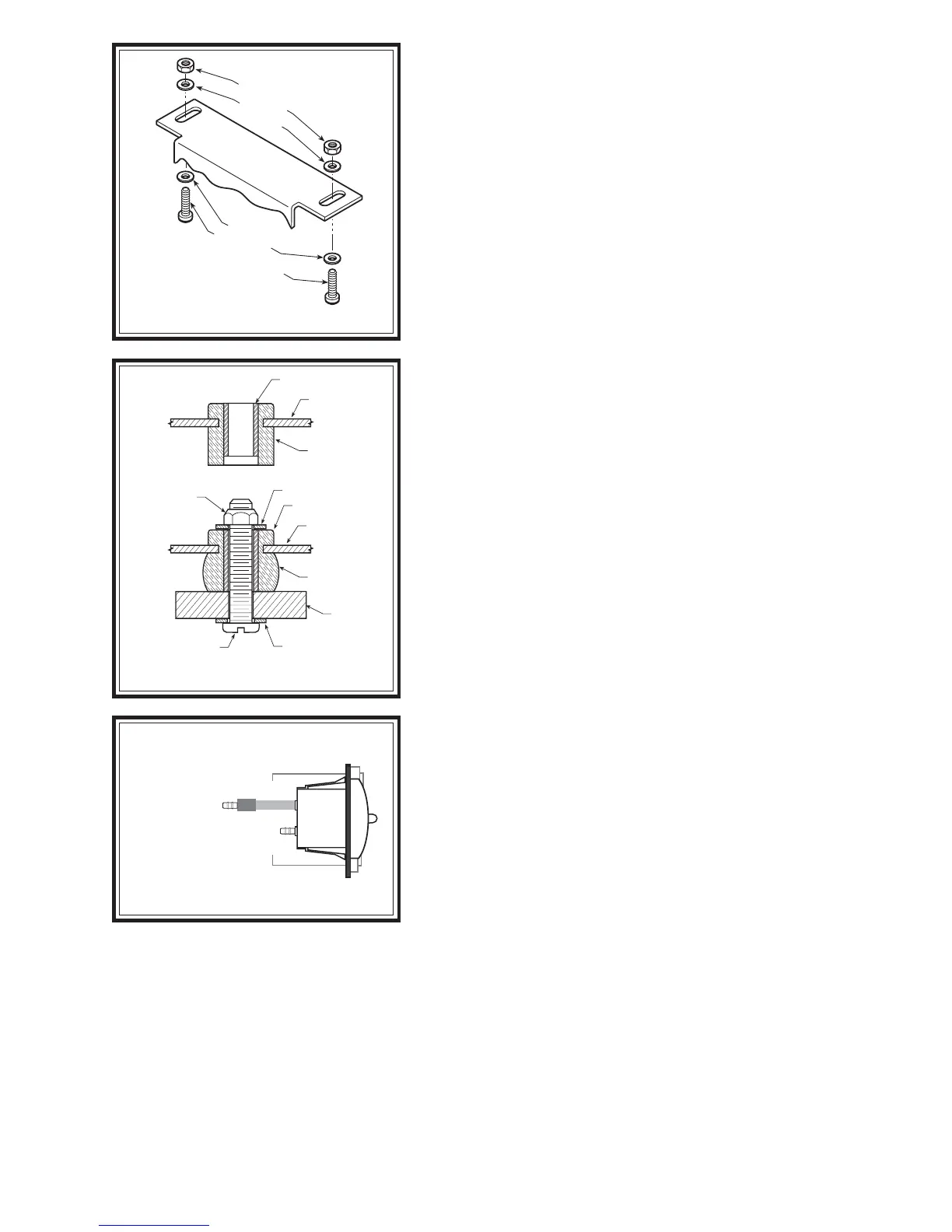

LOCK NUTS

WASHERS

MACHINE SREWS

CONTROL PANEL

BRACKET

WASHERS

S

TEP

1 - S

ELECT

A

MOUNTING

LOCATION

FOR

THE

CONTROL

PANEL

Select a mounting surface under the dashboard or other protected

location. Using the control panel as a template, mark each of the

mounting points with a center punch. Drill a 3/16" diameter hole on each

center mark see Figure "B". Do not attach the control panel at this

time.

S

TEP

2 - P

REPARE

THE

COMPRESSOR

Install the push-to-connect male fitting into the check valve on the

compressor head see Figure "A". Tighten the fitting sufficiently to

engage at least two threads with pre-applied orange thread sealant. DO

NOT OVERTIGHTEN THE FITTING.

S

TEP

3 - M

OUNT

THE

COMPRESSOR

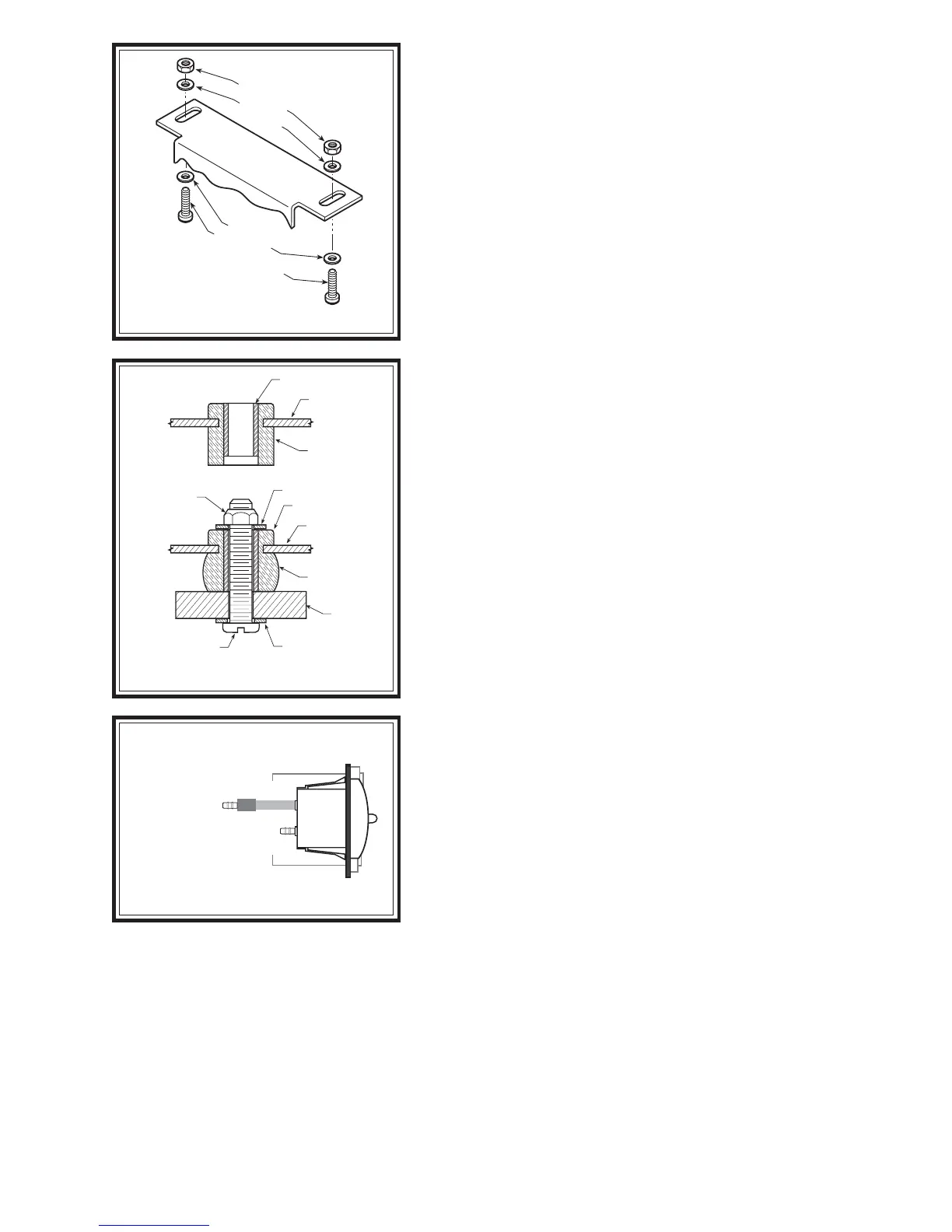

Begin by removing the negative battery cable. Select a convenient

location to mount the compressor. This location should provide ample air

flow and be protected from airborne debris and moisture. The mounting

surface should be rigid to support the compressor, such as under the hood

on a fender well or in a vented storage compartment. The compressor

is oil-less and can be mounted in any orientation necessary for installation.

Using the compressor as a template and a center punch, mark and drill

four 3/16" holes. Any burrs in the holes should be removed to prevent

damage to the rubber isolators. Mount the compressor using the supplied

10 -32 x 1" machine screws, 10 -32 lock nuts, and 3/16" washers see

Figure "C". Maximum vibration isolation can be achieved by properly

mounting the compressor. The machine screw and nut should be

tightened only enough to bottom-out the brass insert see Figure "C".

DO NOT OVERTIGHTEN. Overtightening will crush the brass insert

and the rubber isolator, thereby reducing vibration isolation. Finally,

connect the black wire with the ring terminal from the compressor to a

suitable ground.

S

TEP

4 - R

OUTE

THE

AIR

LINE

Before installing the air line tubing, ensure that there is no pressure

in the air springs. To release the air pressure, remove the valve core from

the manual inflation valves or release the pressure by using a tire gauge

to depress the valve stem.

A) C

OMPRESSOR

TO

CONTROL

PANEL

Cut a piece of air line tubing that will reach from the control panel to

the compressor. Cut the air line tubing as squarely as possible and install

the tubing on to the barbed fitting on the back of the switch marked SUP

(supply) see Figures "A" & "D". Before attaching the air line tubing

to the control panel, soak the end (1") of the air line in hot water for a few

minutes to soften the tubing. Do not use pliers to work the tubing on to

the barbed fitting, as the tubing may be damaged. It may be necessary

to drill a hole in the firewall to route the tubing. Do not fold or kink the

tubing. Ensure that the tubing is protected from sharp edges when

passing through the firewall.

B) C

ONTROL

PANEL

TO

AIR

SPRINGS

Cut a length of air line tubing that will reach from the control panel to the rear of the vehicle. Slide the tubing as

far as possible onto the barbed fitting on the back of the gauge, see Figures "A" & "D". Do not use pliers to work

the tubing on to the barbed fitting, as the tubing may be damaged. Install a T-fitting on the opposite end of the tubing

at the rear of the vehicle. Route a length of air line tubing from the T-fitting to each air spring. Use the suppled nylon

ties to secure the tubing to the vehicle. Make sure that the tubing is protected from sharp edges when passing through

the firewall.

STEP

6 - ATTACH

THE

CONTROL

PANEL

TO

THE

DASHBOARD

Place the air control panel on the dash where the holes were drilled in Step 1. Using the provided machine screws,

lock nuts, and washers attach the air control panel to the dashboard or selected mounting surface see Figure "B".

Figure "B"

Figure "C"

Figure "D"

BRASS SLEEVE

COMPRESSOR

FOOT

RUBBER

ISOLATOR

BRASS SLEEVE

COMPRESSOR

FOOT

RUBBER

ISOLATOR

#10 FLAT WASHER

#10 FLAT WASHER

VEHICLE

MOUNTING

SURFACE

#10 -32 LOCK

NUT

#10-32 x 1 PAN HEAD

SCREW

SIDE VIEW OF CONTROL PANEL

SUP

DEL

TO AIR SPRINGS

BARB FITTING

FROM COMPRESSOR

Loading...

Loading...