10/29/2020 REV. 003 6

4. Install the unit’s airline into the press-to-release airline fitting (see Figure 2).

5. Cut and remove the shipping zip tie strap (see Figure 2).

6. Install a ¼” NPT fitting into the incoming air port on the unit’s filter / lubricator (see Figure 2). The

supply airline should have a minimum ½” I.D. The unit must have a proper air supply (90 – 120 psi and

27-28 cfm) at the motor to generate the torque required to drive the maximum tap capacity for this

unit.

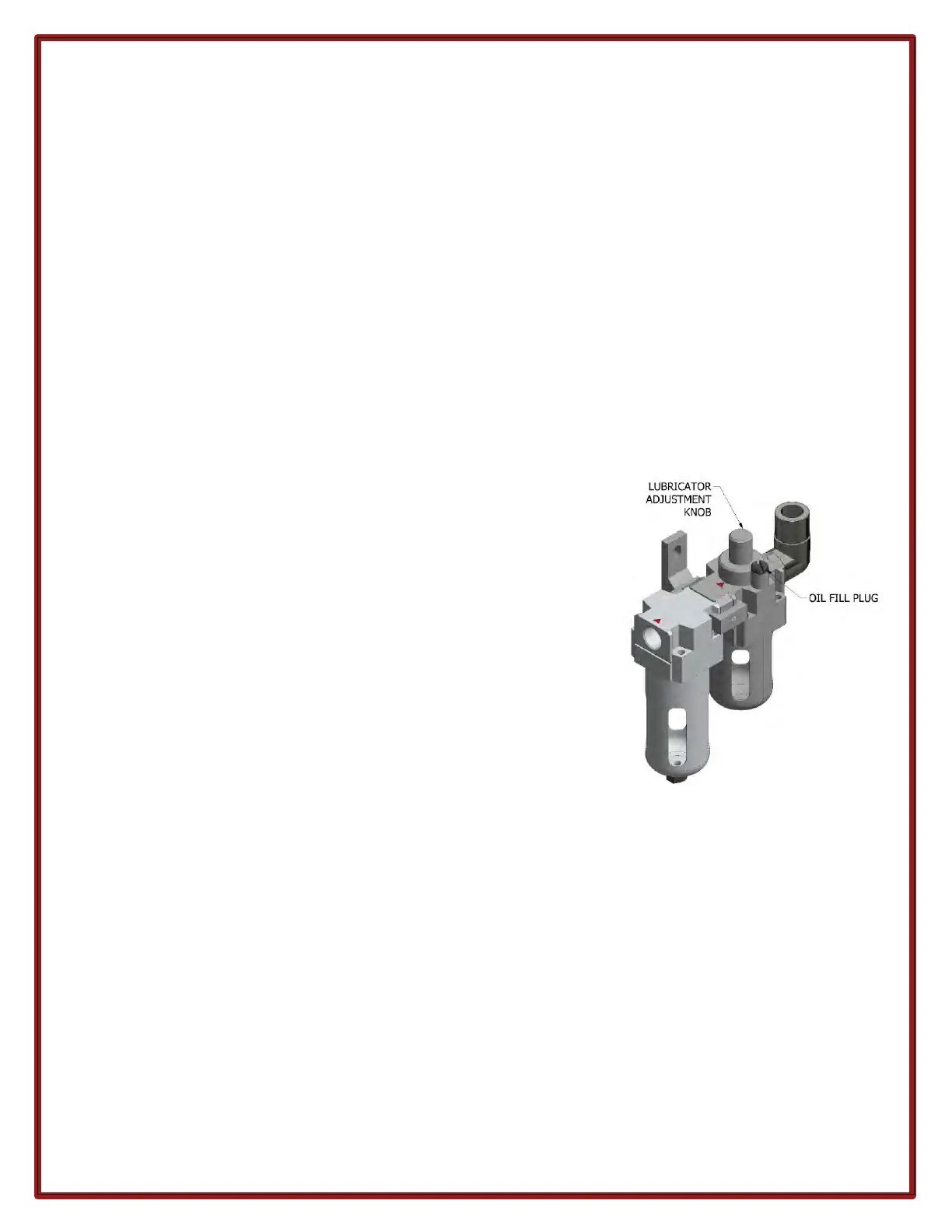

7. Fill the lubricator bowl approximately ¾ full by removing the black fill plug on the top of the lubricator

and pouring oil into the fill port. Use only a quality ISO Grade 32 hydraulic or spindle oil. Never use

Marvel Mystery Oil, synthetic air tool oil, or similar products.

8. With the motor running, slowly adjust the lubricator adjustment

knob (see Figure 3) so 1-3 drops of oil are dispensed per minute.

The site glass to see the drops is located in the adjustment knob.

Clockwise decreases the flow, counter-clockwise increases it.

NOTE: It may be necessary to open the adjustment knob

considerably before the oil starts to drip. Once oil starts to drip,

slowly close the adjustment knob to achieve the target drip rate

of 1-3 drops per minute.

9. The filter is equipped with an auto drain and will automatically remove water from the filter bowl.

10. Check the counterbalance of the unit.

a. The unit comes counterbalanced to factory specifications.

b. The counterbalance can be adjusted to meet the operator’s preference.

11. To adjust the counterbalance, refer to the counterbalance adjustment page of this manual.

12. The unit is now ready for use.

Loading...

Loading...