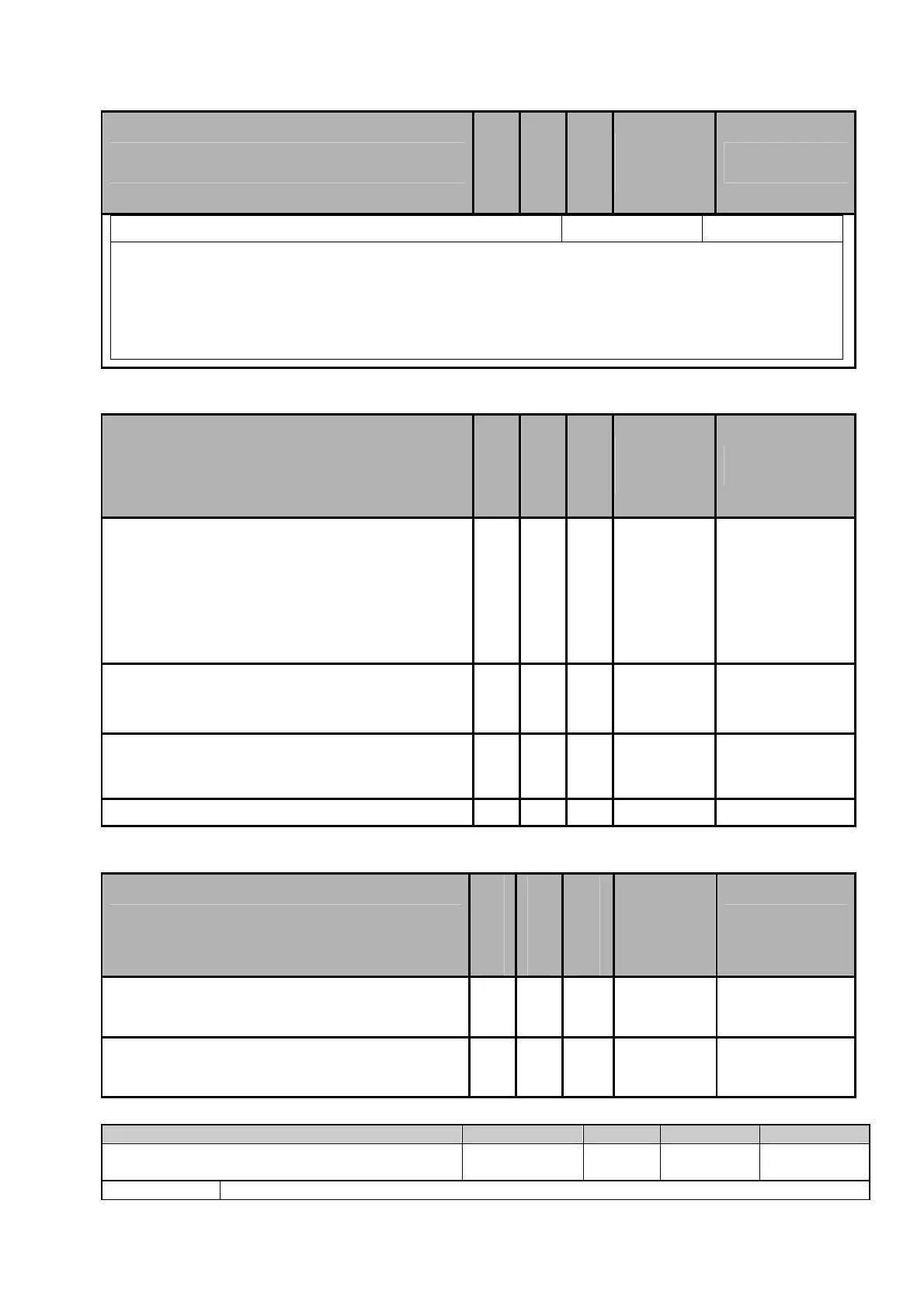

Document Title Document No. Revision

Date Section

Supplement S3 to the AMM CTLS-LSA –

CTLS-LSA with ROTAX 912iS

AF 0480 0011 00 05-Aug-12 05-20-3

Approval Ref.: Approved on the Basis of Manufacturer Self Declaration

Inspection and/or Required Maintenance

Checklist

100hour

Annual

Other Times

Minimum

Level of

Certification

Initials /

Remarks

Check fuel valve off function

Notes:

05-20.2.4 Post Run-Up, Pre-inspection and Preparations

Inspection and/or Required Maintenance

Checklist

100hour

Annual

Other Times

Minimum

Level of

Certification

Initials /

Remarks

Airframe, engine, propeller

Perform a walk around to detect damage, fluid

leaks or other abnormalities,

Check visual the installation geometry between

fuselage/ wing/ empennage and engine/ propeller/

cowling

Check leveling of aircraft on ground.

Pilot/Owner

Engine cowling

Remove engine cowling.

Refer to Section 71-00.3.1

Pilot/Owner

Spinner

Remove spinner as defined in the basic aircraft

AMM

Pilot/Owner

Make record of all malfunctions and abnormalities

Pilot/Owner

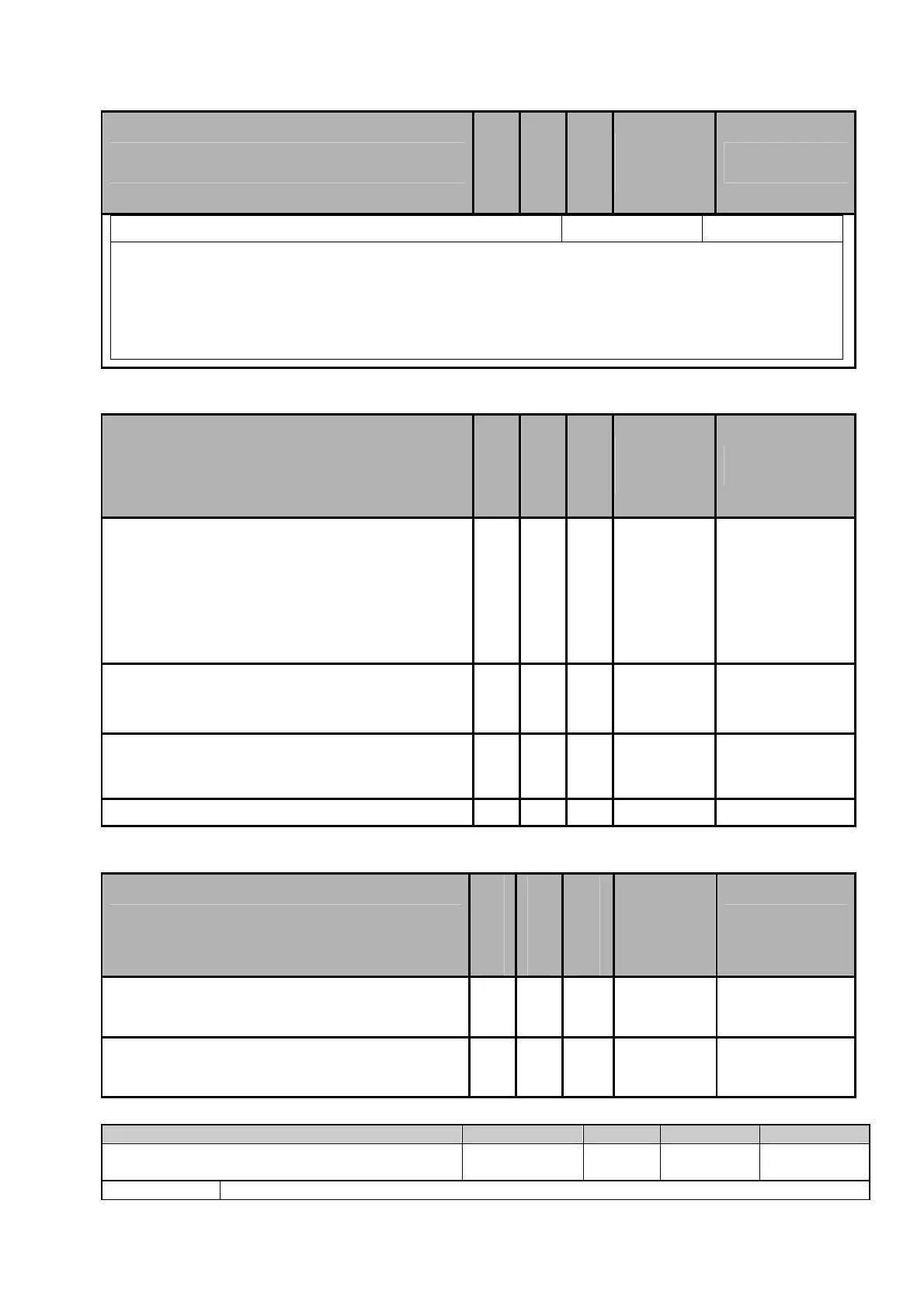

05-20.2.5 Propulsion System

Inspection and/or Required Maintenance

Checklist

100hour

Annual

Other Times

Minimum

Level of

Certification

Initials /

Remarks

Cleaning. Clean the engine as required in the

Maintenance Manual for ROTAX

®

Engine Type

912 Series.

Pilot/Owner

Engine. Conduct 100 hrs inspection as per

Maintenance Manual for

ROTAX

®

Engine Type 912 iS Series.

A&P

Loading...

Loading...