Document Title Document No. Revision

Date Section

Supplement S3 to the AMM CTLS-LSA –

CTLS-LSA with ROTAX 912iS

AF 0480 0011 00 05-Aug-12 75-00-4

Approval Ref.: Approved on the Basis of Manufacturer Self Declaration

75-00.3 Maintenance Practices

75-00.3.1 Cooling Inspection

75-00.3.1.1 Type of Maintenance

Line

75-00.3.1.2 Minimum Level of Certification

Pilot/Owner

75-00.3.1.3 Procedure

A. Recommended Special Tools and Parts

Item Quantity Unit

None

B. Cooling Inspection

Step Action Reference

1 Inspect connections for leaks.

2 Check coolant level. Replenish if required.

3

Inspect cylinders for dents, cracks and cooling jacket for chafing marks and burn

spots. If damage observed – replace cooling jacket.

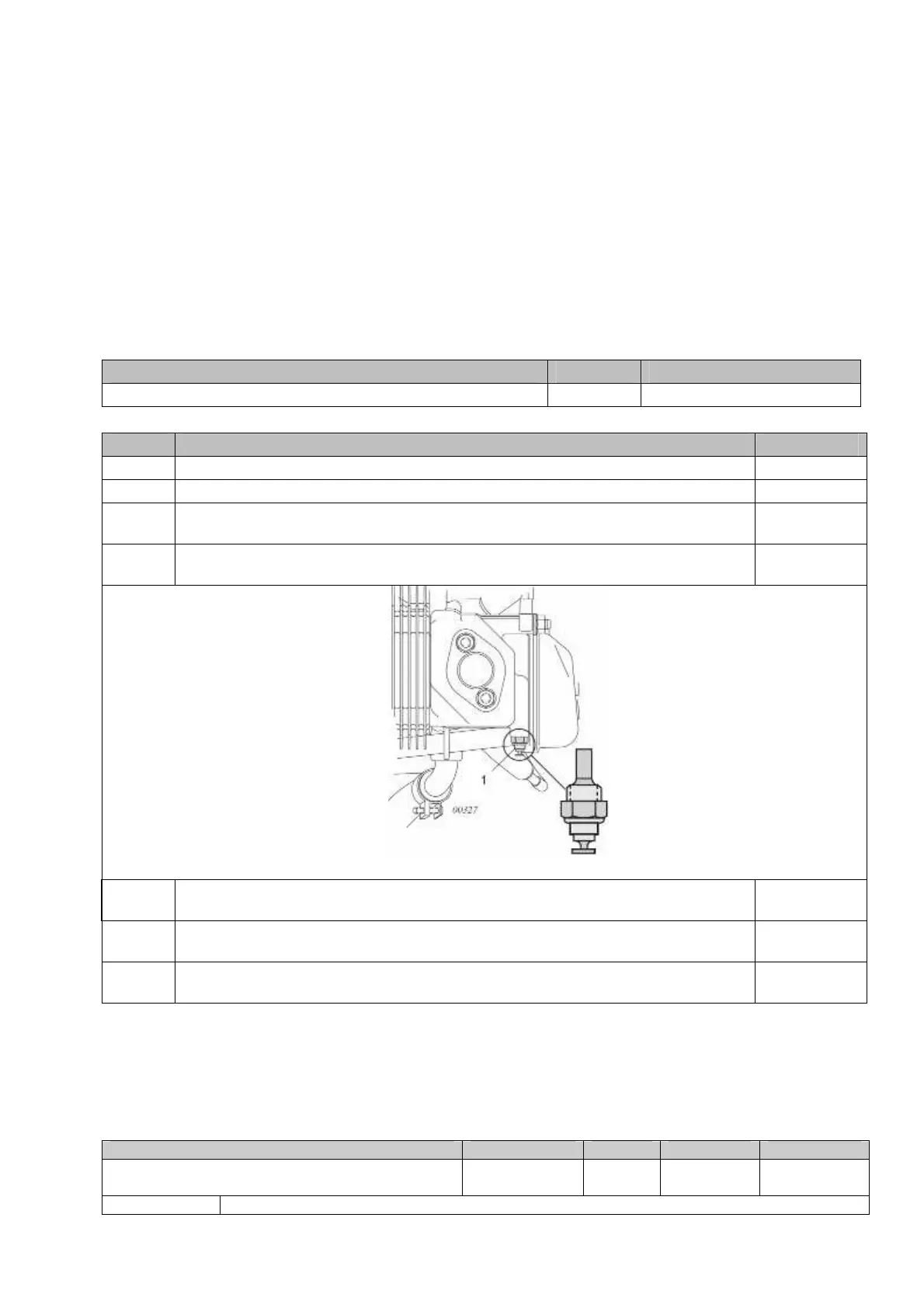

4

Check the securing and conditions of Cylinder Head Temperature (CHT) sensor.

Tighten sensor with torque 10Nm and secured with Loctite 221.

Fig. 75-00-4. Cylinder Head Temperature sensor.

5

Check conditions of cooling lines and connections for leaks. Check cooling lines

for damage, overheating marks. Replace cooling line or clamp if required.

6

Inspect Expansion Tank, Pressure Cap and Overflow Bottle for damage and

abnormalities.

7

Inspect Radiator Unit and its mounting points. Check Shock mounts conditions

and connections tightening.

Loading...

Loading...