PV350 English Instruction Sheet

Page 6

2. Connect the pressure regulator to the nitrogen bottle and the

reference pressure gauge to the pressure regulator. The nitrogen

bottle must have >750 psi.

3. Verify the condition of the battery and if necessary, replace the

battery. (Refer to Figure 2.)

4. Remove the top cover of the module and connect it to the mV input

of the DMM. Set the scale to measure 500 mV (0.1 mV resolution).

5. Turn on the PV350 and allow it to warm up for two minutes.

6. Set the PV350 to the psi range.

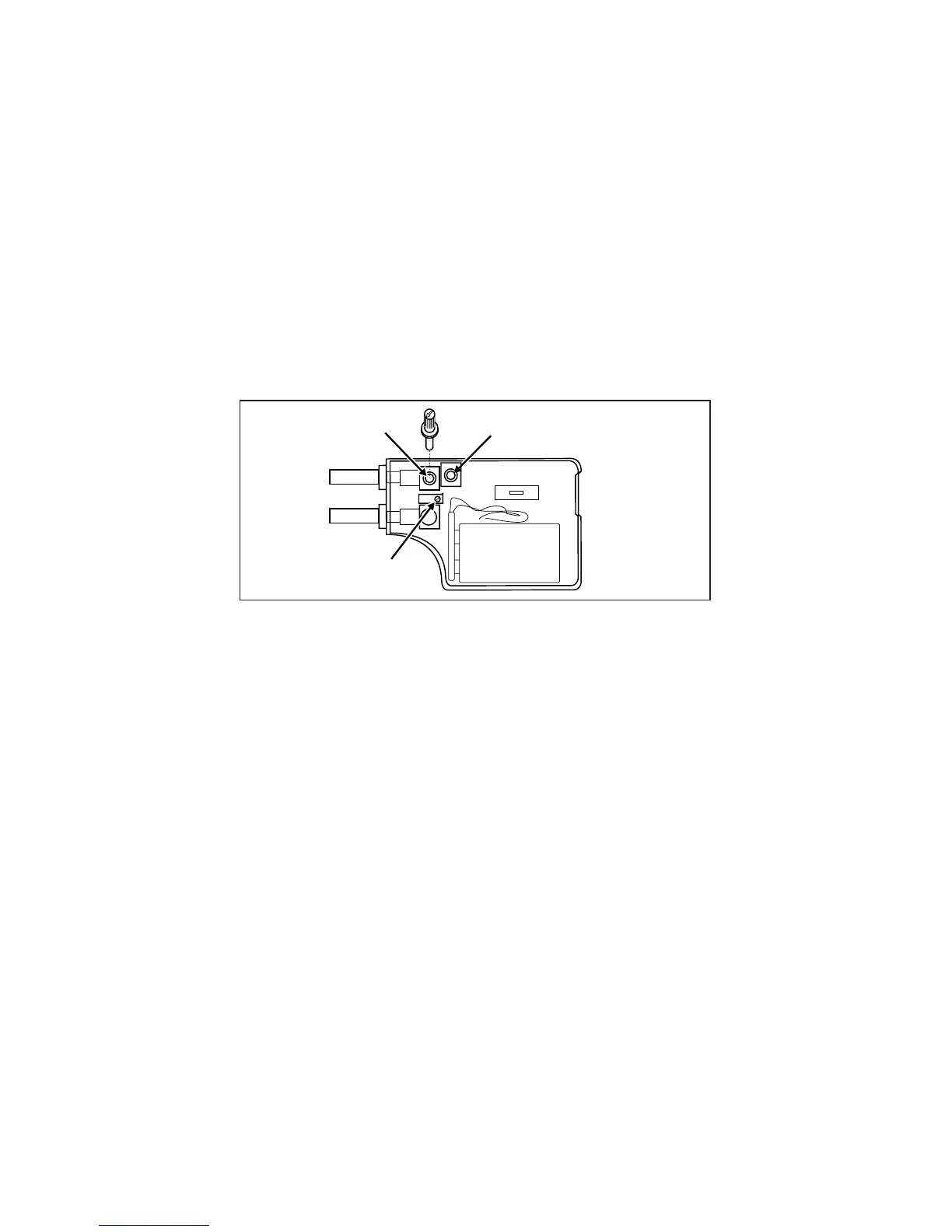

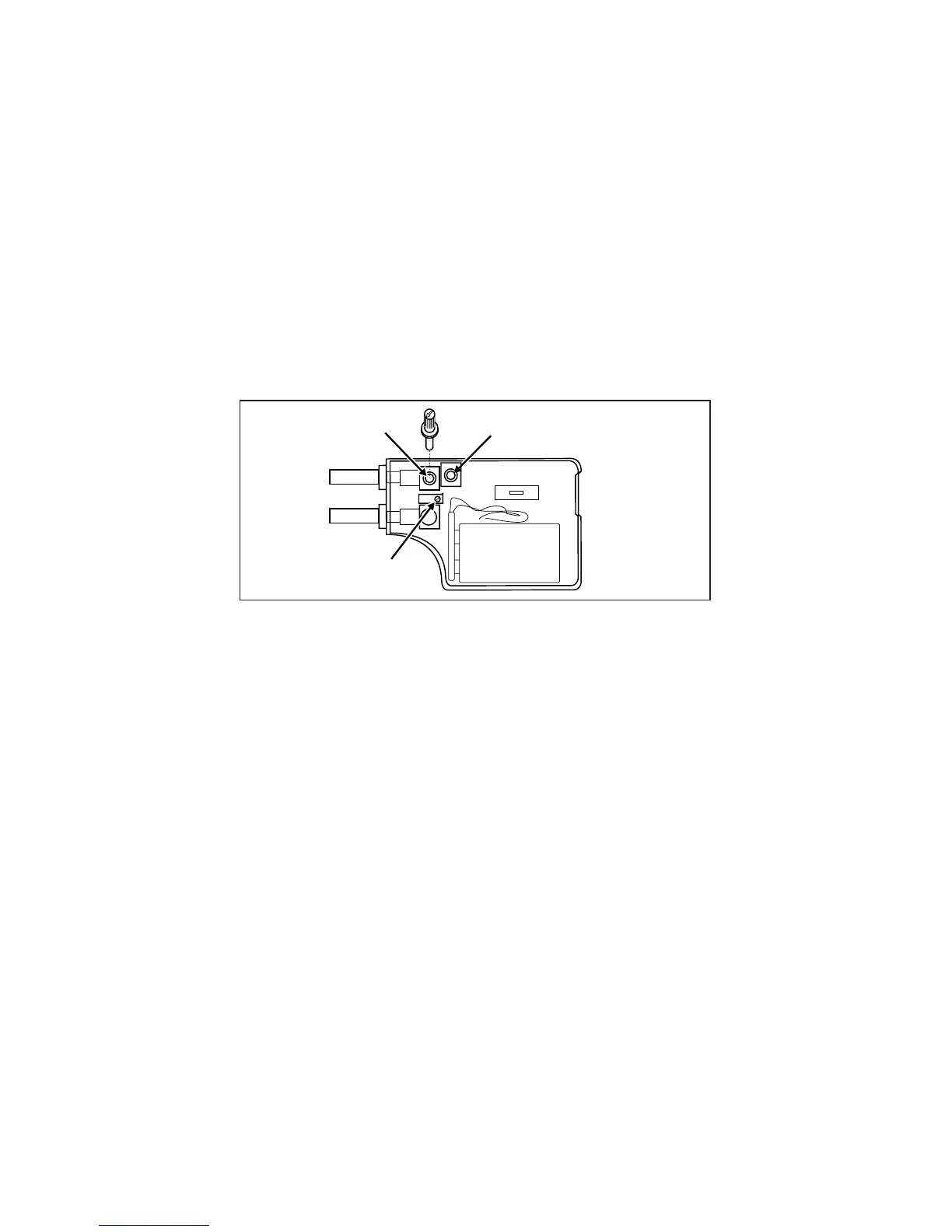

7. Center the ZERO potentiometer, R3 (see Figure 5). Remove the

knob from R3 and insert it into R4 (the coarse zero adjustment).

With no pressure applied, set the reading to 0 mV ±0.3 mV. Insert

the knob back into R3, and adjust the final reading to 0.0 mV,

±0.1 mV.

R4

R3

R16

Figure 5. Calibration Adjustment Points

8. Connect the sensor to the pressure reference and nitrogen bottle

pressure calibration system.

9. Adjust the pressure regulator to about 250 psi. The readings on the

reference pressure gauge and the reading from the PV350 should

agree within ±0.1 % of the point, ±-0.3 psi: approximately ±0.6 mV

or ±0.6 psi. Adjust R16 as necessary.

10. Adjust the pressure regulator to about 350 psi. The readings on the

reference pressure gauge and the PV350 should agree within

±0.1 % of the point, ±0.3 psi: approximately ±0.7 mV or ±0.7 psi. If

necessary, adjust R16 to bring the reading into specification and

recheck the 250 psi point. It may be necessary to repeat steps 9 and

10 until both points are within specification.

11. Reduce pressure to zero and switch the module OFF.

How to Verify Calibration

1. Connect the sensor (transducer) to a pressure calibration standard,

and plug the module into the DMM.

2. Be sure the system is vented, then zero the module.

3. Enter the pressure settings shown in Table 2 and check for the

indicated readings

Loading...

Loading...