Page 2 • MN01029 Issue/Rev. 0.5 (6/11)

Section 1 – General Information and Description

It is suggested that a detailed record be maintained

for each meter. Nameplate data, clearances, progres-

sive totalizer readings, meter factor, parts used, and

other similar information provide background material

for scheduling a preventive maintenance program. An

increase in meter factor drift against throughput can be

used as the basis for making an inspection.

The time of the first inspection must be based on the

operating conditions imposed by the installation. Flow

rate, lubrication properties of the fluid, and the possibility

of abrasive contaminants are points to consider. Then,

at the time of inspection, the condition of the meter

should indicate whether the inspection interval can be

lengthened or shortened.

All parts, as they are removed, should be thoroughly

washed and cleaned in solvent. Parts that are worn

enough to affect operation or calibration should be re-

placed. All parts that are nicked, gouged, or have rough

places on them, should be dressed with a fine file or

crocus cloth, as conditions warrant.

Before any disassembly is performed on the meter, be

sure that the trouble is in the meter.

1. Check that meter is being operated within the proper

flow rate. Refer to the nameplate on the side of the

meter.

2. If rotor does not turn freely, adjust end clearance. See

Adjusting Rotor End Clearances, Page 9.

3. Check calibrator for proper operation.

4. Check air eliminator and strainer assembly.

5. Check valve operation.

After all other accessories have been checked and found

to be operating normally, the meter should be checked.

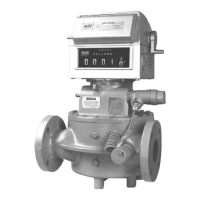

Description

Smith Meter

®

single-case rotary meters are of the posi-

tive displacement type. The metering mechanism is a

rotor assembly set in the housing. Pipe connections are

confined to the housing, which means the rotor assem-

bly can be removed by taking off the cover assembly and

lifting the rotor assembly out. Inspection, maintenance,

and service is greatly simplified.

The measuring function is accomplished in a chamber

of precise volume created by the moving blades, rotor,

housing, and cover. There is a smooth flow of product

through the meter. The blades rotate around a fixed

cam which causes them to move out to, but not touch,

the body of the meter. Four chambers per revolution are

formed as the rotor and blades are turned by product

flow.

FMC Technologies Measurement Solutions, Inc. pro-

vides a meter variation with tungsten carbide trim to

resist the accelerated wear that can be caused by im-

1-1/2"

3/4"

3/4"

9"

9"

2" Dia.

Figure 1

Figure 1A

purities such as sand and iron sulfide and also by the

low lubricity of condensates. This variation uses solid

tungsten carbide journal rotor and thrust bearings. In

addition, blade bearings’ size and weight have been

reduced to minimize the rotational inertia of the cam

followers and the wear resistance of the bearings and

cam have been substantially increased. Also, the rotor

and jackshaft gear assemblies have been changed to

hardened stainless steel.

Figure 2 — Spider and Bushing

1 Consists of feeler gauge soldered to 15" rod. An extension rod (22") and coupling is available as Part Number 515250.

Loading...

Loading...