8

Chapter

I-General

Engine Repair

(2)

H

OR

M

SERIES

ENGINE

INSTALLATION.

To

install

the

engine, guide it into

the

engine

compart-

ment. Lower the

engine

and

move

it

back until the

transmission

main

shaft enters

the

clutch disc spline.

Shift the transmission into

any

gear.

This

will

prevent

the main

shaft

from turning.

It

the

spline grooves

do

not

mesh,

slowly

turn the crankshaft until the main

shaft

slides

mto

the

clutch

disc spline.

Install

the

transmission

to

flywheel

housing

bolts

and

torque

them

to

40-50

foot-pounds.

Lower

the

engine

to

the

front

supports

and

install

the

front

support

bolts

.

Disconnect

the

crane and

remove

the

engine lift

bracket.

To

complete

the

engine

installation,

connect

the

muffler inlet pipe, clutch release bearing spring,

and

flexible fuel line.

Connect

th~

choke

wire,

throttle

link-

age, starter cable,

vacuum

hose,

oil

pressure sending

unit wire, temperature

sending

unit

wire, generator

wires, ignition

switch

to

coil wire, and

heater

hoses.

Install the radiator and

connect

the

radiator hoses.

Install

and

secure

the

grille

assembly.

Install

the

front

wheel. Install

the

dash

panel, floor pan, air cleaner and

flexible

tube,

and

hood.

Fill

the

crankcase

and

cooling

system

according

to

the

prevailing temperatures.

(3)

R

SERIES

ENGINE

REMOVAL.

Remove

the

generator, carburetor, crankcase inlet

pipe

and fuel

pump.

Install

the

engine

lift

hook

assembly

and

take

up

the

slack

in

the

cables

with

a

portable

floor crane.

Remove

the bolts which secure

the

transmission

to

the

flywheel housing.

Move

the

engine

away

from

the

trans-

mission. Lift it high

enough

to

clear the chassis and

carefully

maneuver

the

engine

from

the

engine com-

partment.

(4)

R

SERIES

ENGINE

INSTALLATION.

To

install the

engine

, guide it into

the

engine

compart-

ment.

Lower

the

engine

and

move

it back until the

transmission

main

shaft enters the clutch disc spline.

Shift

the

transmission into gear

to

prevent

the

main

shaft from turning.

If

the spline grooves

do

not mesh,

slowly

turn

the

crankshaft

until

the

main

shaft

slides

into

the

clutch

disc

spline.

Install

the

transmission

to

flywheel

housing

bolts

and

torque

them

to

40-50

foot-pounds

.

Lower

the

engine

to

the

front

supports

and

install

the

front

support

bolts.

Disconnect

the

crane and

remove

the

engine

lift hook

assembly.

Install

the fuel pump, crankcase inlet pipe

carburetor, and generator.

To

complete

the

engine

installation, connect

the

muffler inlet pipe.

clutch

release bearing spring, and

flexible fuel line.

Connect

the

choke

wire, throttle link-

age, starter

cable

,

vacuum

hose,

oil

pressure sending

unit wire, temperature

sending

unit

wire, generator

wires, ignition

switch

to

coil wire,

and

heater

hoses.

Install

the

radiator and

connect

the

radiator hoses.

Install and

secure

the grille

assembly.

Install

the

front

wheel

, dash

panel

, floor pan, air cleaner and flexible

tube,

and

hood.

Fill

the

crankcase

and

cooling

system

according

to

the

prevailing temperature.

c.

Parcel

Delivery.

Drain

the

crankcase

and

cooling system.

Remove

the

hood

and

radiator

support

bar.

Disconnect

the

upper

radiator hose.

Remove

the

fan

shrOUd

from the radi-

ator and lean the shroud against the engine. Disconnect

the lower radiator hose,

remove

the

radiator support

assembly

with

the

radiator, and

remove

the fan shroud.

Remove

the

engine

compartment

rear cover. Open

the

engine

compartment

front cover and

attach

the

hook

at

the

left

corner near

the

hinge

to

keep

it open.

Remove

the weatherstrip retaining panel

at

the rear

edge

of

the

engine

compartment

rear cover.

Remove

the air cleaner and flexible tube.

Disconnect

the generator wires, ignition

switch

to

coil wire, tem-

perature

sending

unit wire, oil pressure sending unit

wire,

vacuum

hose

at

the

intake manifold, starting

motor

cable

at

the

starter, throttle linkage, choke wire,

and heater hoses.

Disconnect

the

flexible fuel line,

muffler inlet pipe, clutch release bearing spring, and

hand

brake

cable

where

it

is

clipped

to

the

trans-

mission.

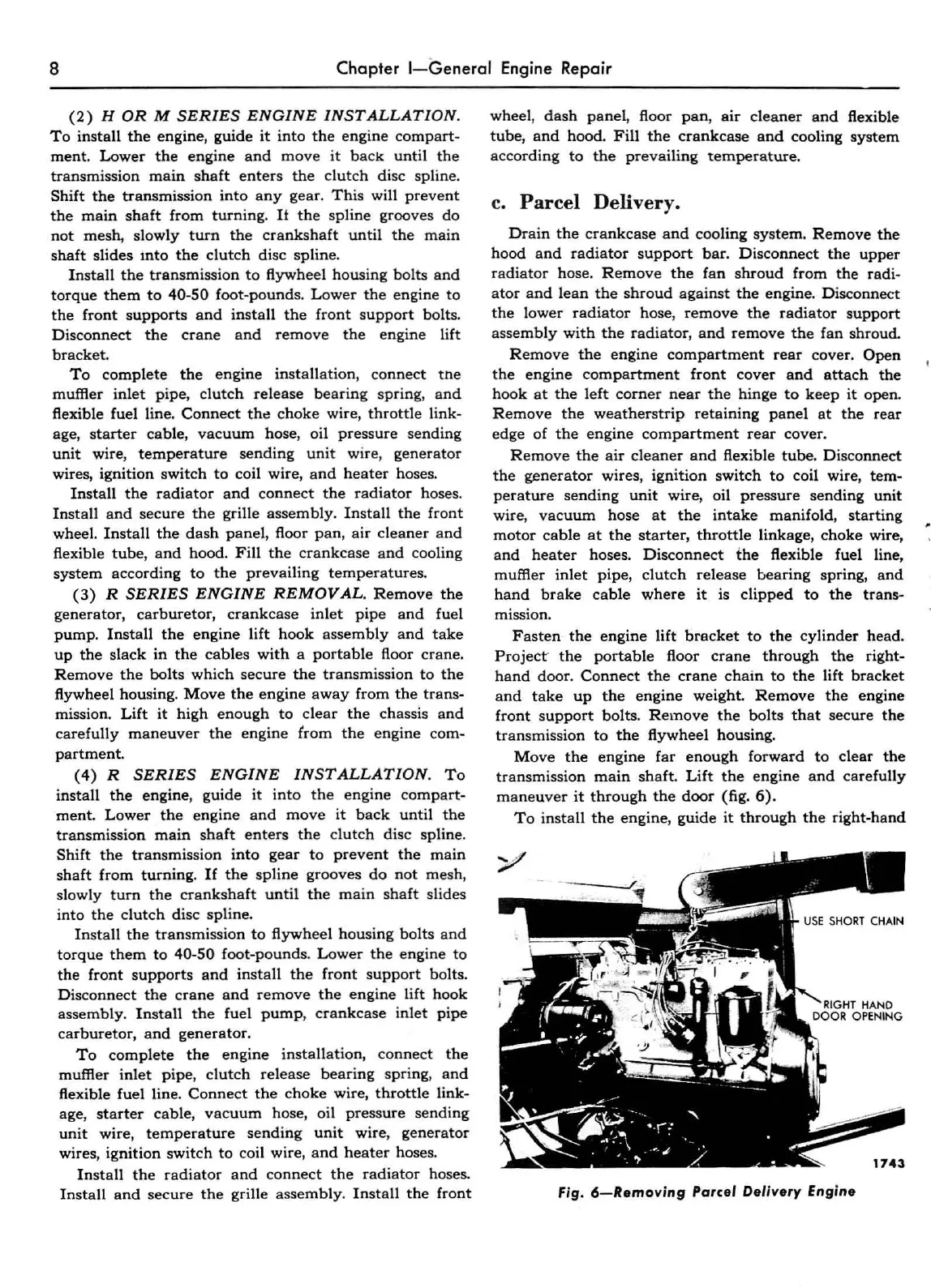

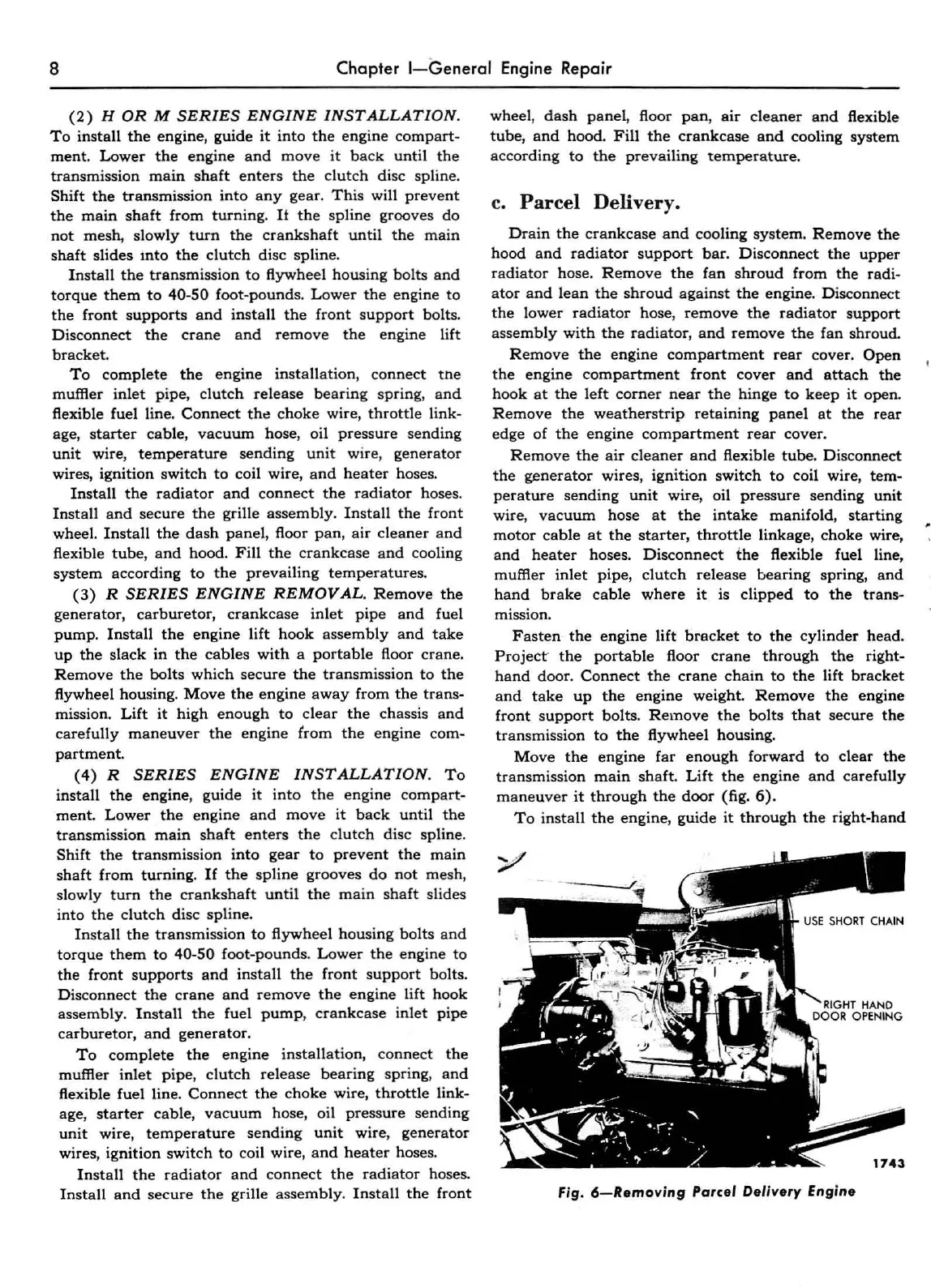

Fasten

the

engine

lift

bracket

to

the

cylinder

head.

Project'

the

portable

floor

crane

through

the

right-

hand

door

.

Connect

the

crane

chain

to

the

lift

bracket

and

take

up

the

engine

weight.

Remove

the

engine

front

support

bolts.

Remove

the

bolts

that

secure

the

transmission

to

the

flywheel housing.

Move

the

engine

far

enough

forward

to

clear the

transmission

main

shaft.

Lift

the

engine

and carefully

maneuver

it

through

the

door

(fig.

6).

To

install

the

engine,

guide

it

through

the

right-hand

Fig.

6-Removing

Parce'

Delivery

Engine

Loading...

Loading...