14

|

Chainsaw Operator’s Manual

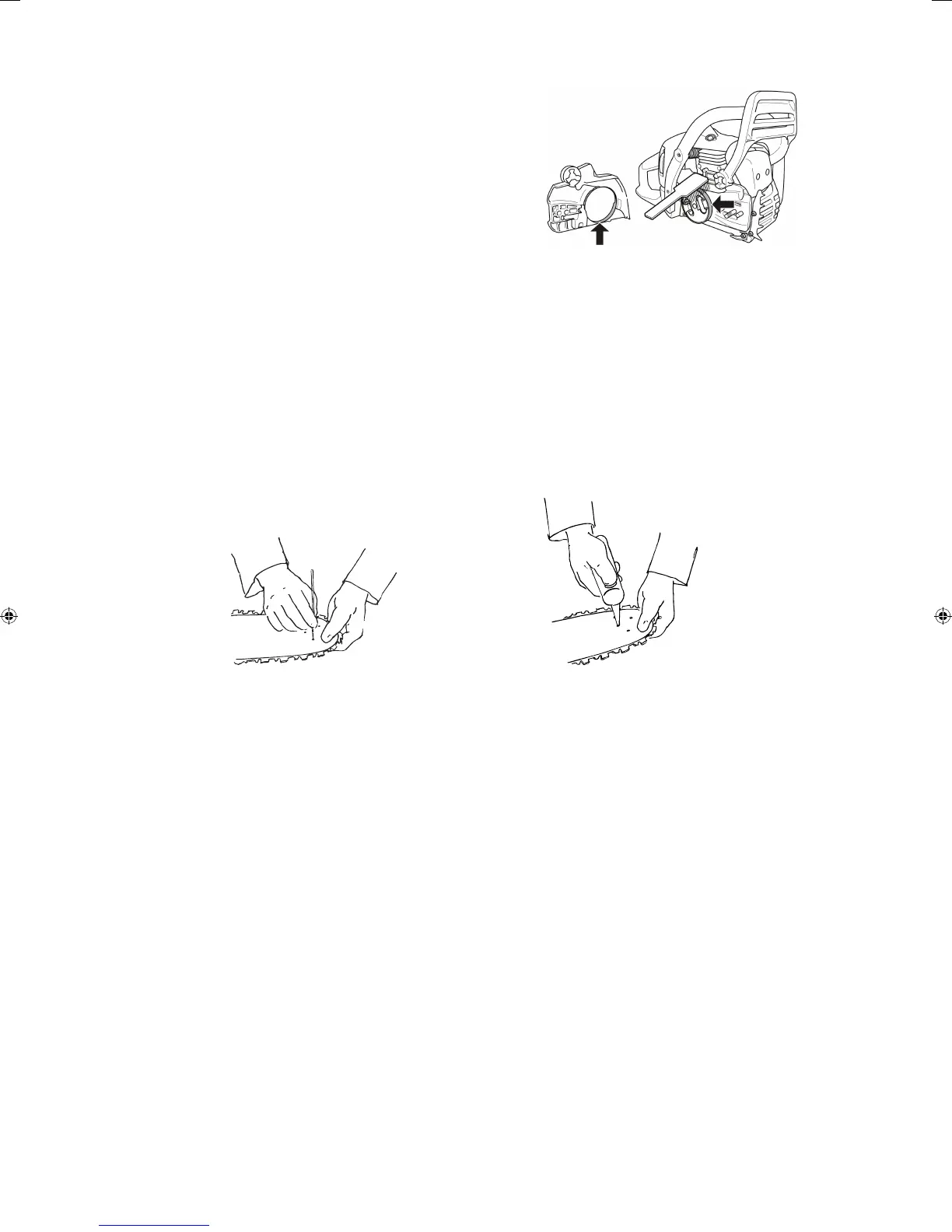

Chain brake

• Thoroughly clean, particularly around brake band and

operating mechanism.

• Frequent operation of the brake throughout the day

will keep the brake’s internal components free from

an accumulation of dirt and saw dust.

• Ensure correct operation.

Saw chain and guide bar

• Remove side cover, clean and inspect.

• Remove saw chain and visually inspect chain and bar

for wear and cracks.

• Clean out groove, working from the nose backwards. Remove any burrs.

• Clean oil holes.

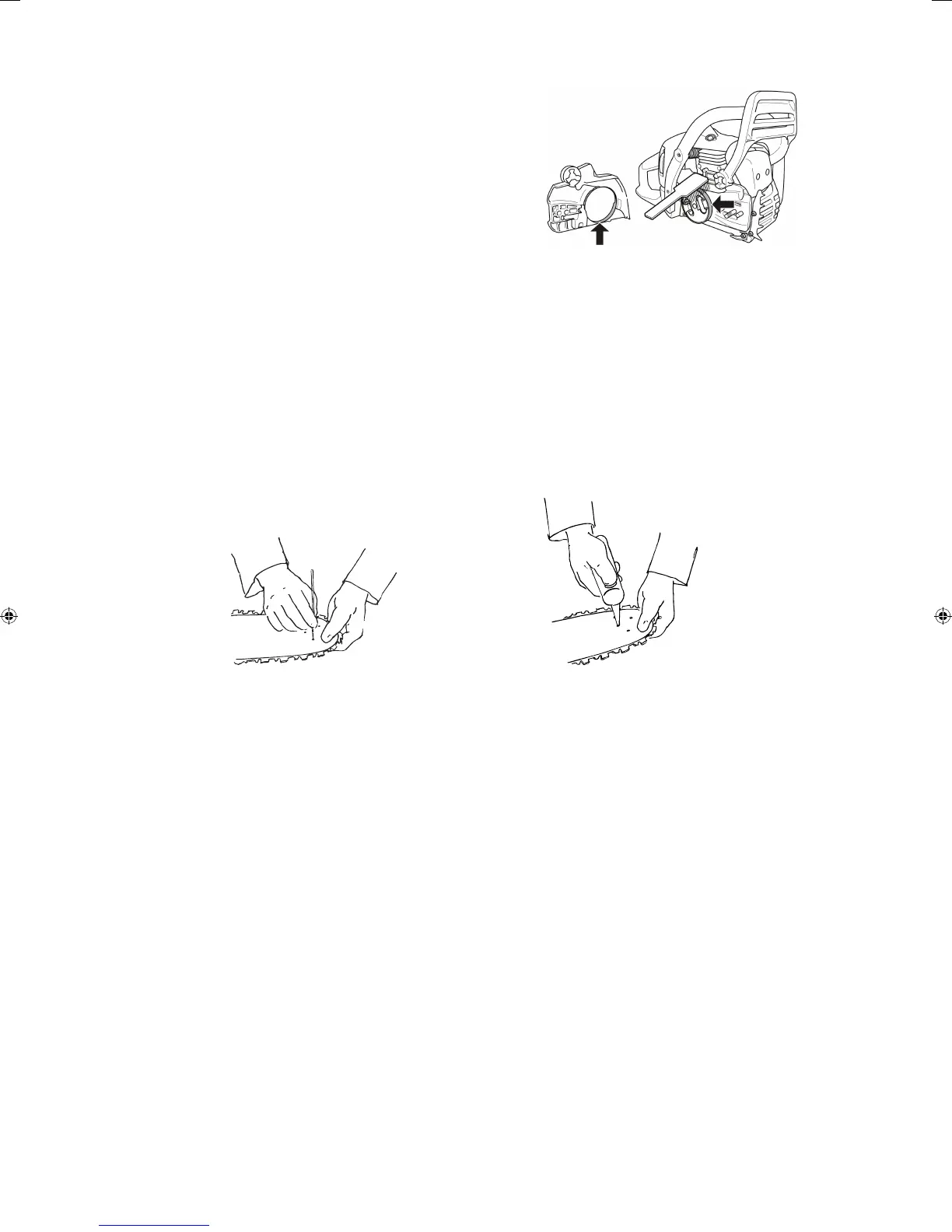

• Sprocket nose:

− clean out debris

− ensure sprocket rotates and check for broken teeth

− grease, if appropriate.

Figure 18: Cleaning and greasing the sprocket nose.

• Reverse the guide (cutter) bar to equalise wear.

• Install chain and sharpen, or fit spare chain. It may be necessary to change or sharpen the chain

several times during the day.

• Tension chain correctly.

Loose screws/nuts

• Check screws/nuts for tightness. Do not over-tighten.

Safety features

• Check all safety devices are operational.

Fill fuel and chain oil tanks

• Filling the tanks at the end of the day will minimise condensation of water in the tanks during

storage.

Figure 17: Cleaning the chain brake.

070902 Chainsaw Manual 3pp.indd 14 2/09/09 17:17:15

Chainsaw Operator's Manual:

Chainsaw Safety, Maintenance and Cross-cutting Techniques,

by ForestWorks

Published by CSIRO Publishing, 2009, 64pp

©ForestWorks 2009

http://www.publish.csiro.au

Loading...

Loading...