Chainsaw Operator’s Manual

|

13

4. Chainsaw maintenance

Regular maintenance of the chainsaw, in accordance with the manufacturer’s advice, is essential for

safe, reliable and trouble-free operation. Chainsaw breakdowns are costly both in repair expenses

and lost production. A professional attitude to maintenance means paying attention to:

• the recommended frequency of servicing

• careful inspection of all components

• cleanliness of the saw and related equipment

• reporting of problems and faults promptly

• arranging for specialist repairs when required.

Do not operate the saw if any components become defective, particularly any safety devices.

Powerhead and guide bar maintenance

Daily service (or frequent service as required)

The maintenance schedules are based on a regular daily engine operating time of 6 to 8 hours.

However, when working in particularly dirty or dusty conditions, or when cutting dry timber, the

service intervals may need to be shortened. The tasks below should be carried out daily according

to manufacturer’s specifications:

Cleaning

• Thoroughly clean saw body, air intake vents and cooling fins.

• Use plastic or wooden scrapers, not metal screwdrivers which can damage paintwork, leading

to corrosion.

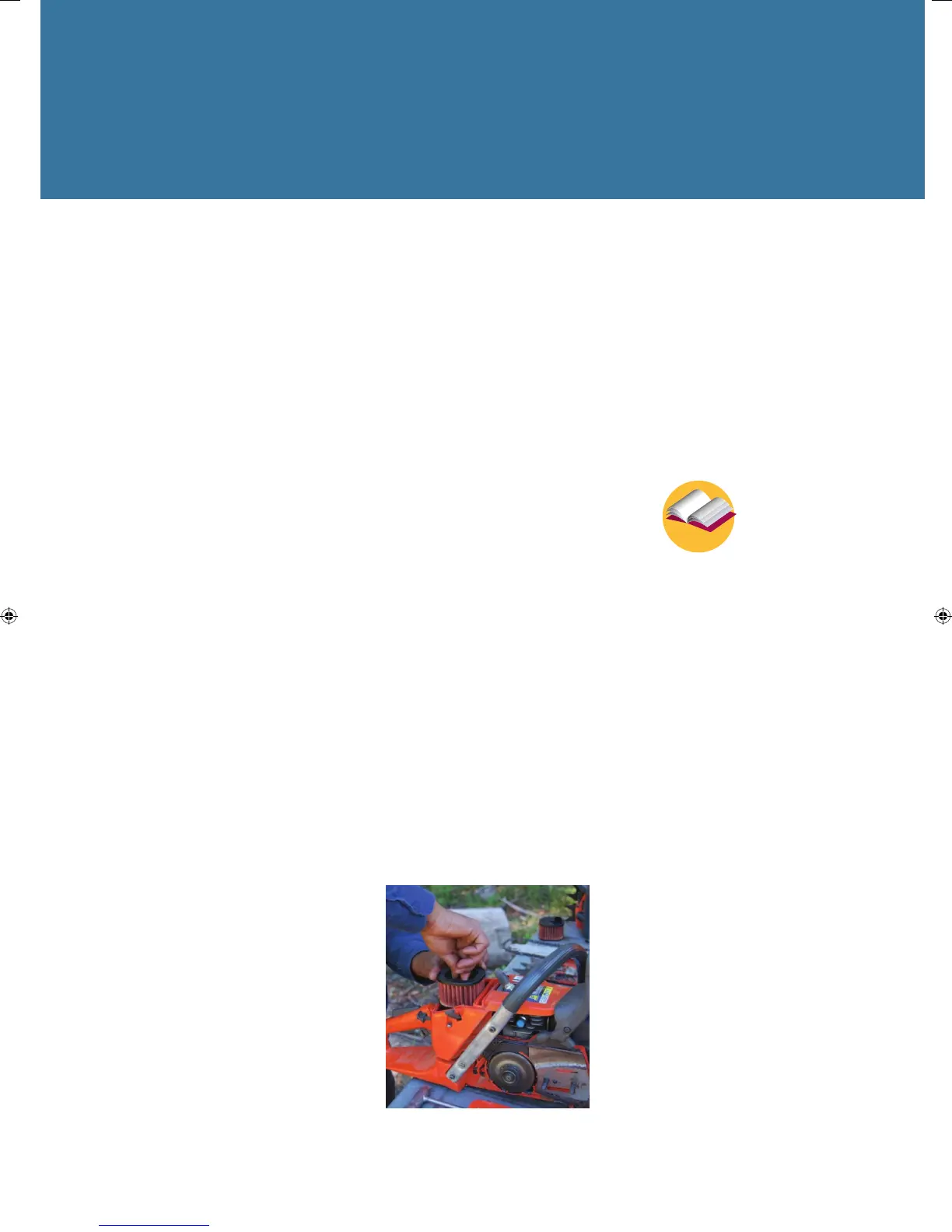

Air filter

• Before removing filter, apply the choke to close off the carburettor throat to prevent the entry

of foreign matter. Remove and check the filter for damage and penetration of foreign material.

Clean as per manufacturer’s recommendations. Replace filter if damaged.

• A spare filter is useful to have as a replacement as required.

Figure 16: Checking the air filter.

R

E

F

E

R

M

A

N

F

A

C

T

U

R

E

R

S

R

e

c

o

m

m

e

n

d

a

t

i

o

n

s

070902 Chainsaw Manual 3pp.indd 13 2/09/09 17:17:15

Chainsaw Operator's Manual:

Chainsaw Safety, Maintenance and Cross-cutting Techniques,

by ForestWorks

Published by CSIRO Publishing, 2009, 64pp

©ForestWorks 2009

http://www.publish.csiro.au

Loading...

Loading...