32

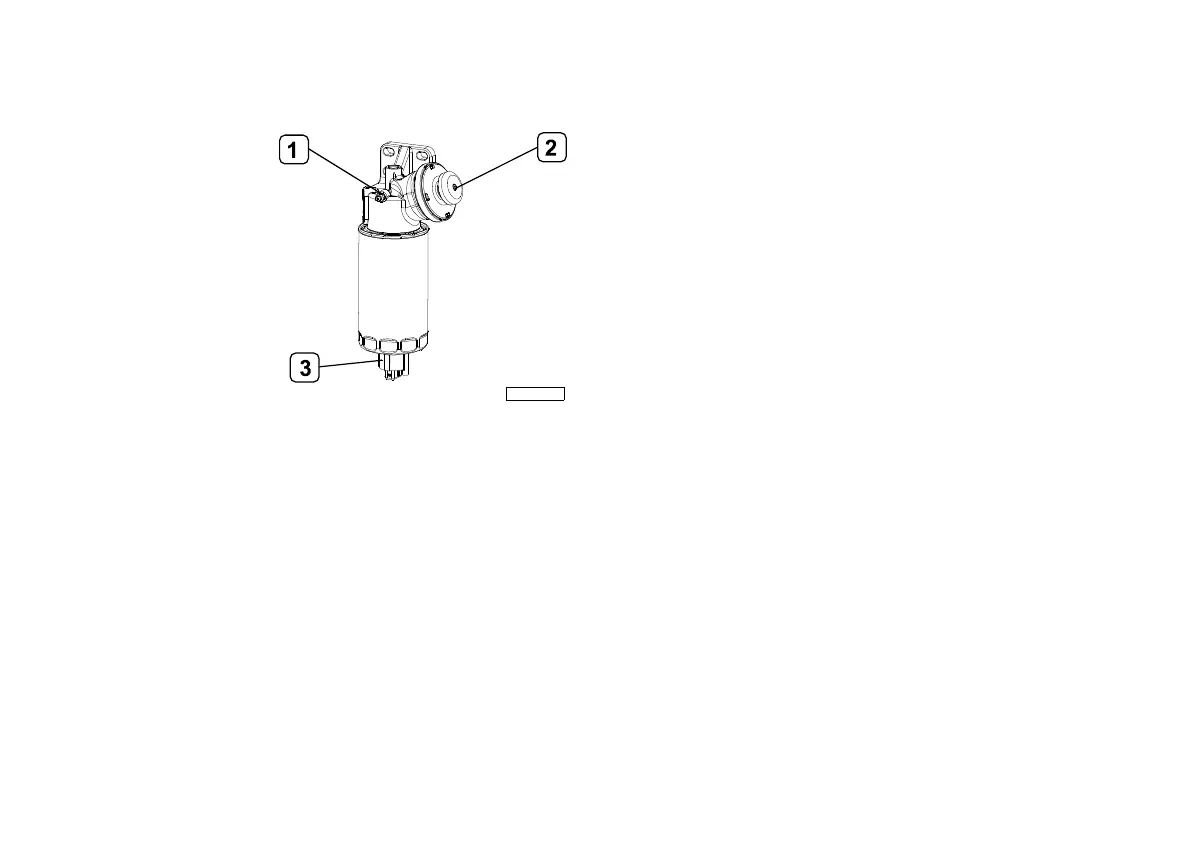

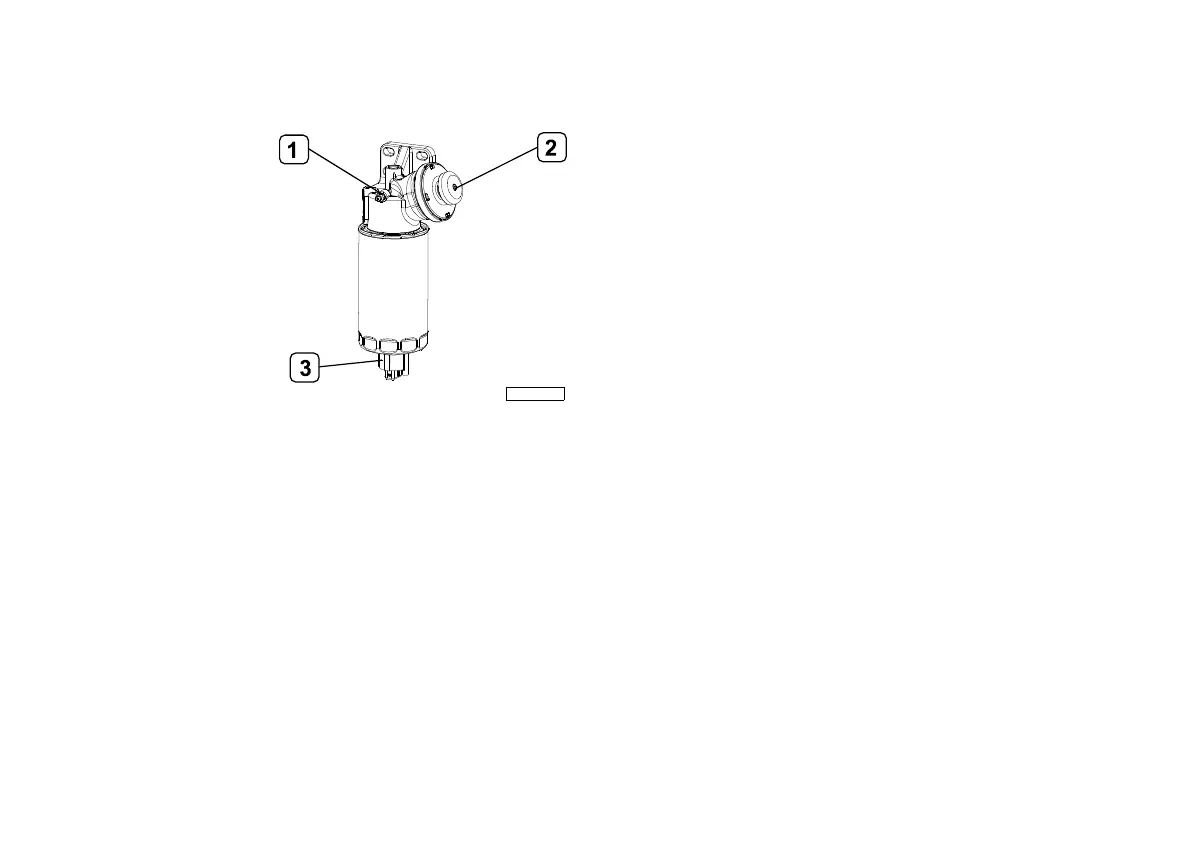

Changing the fuel pre-filter

Only proceed with the engine stopped.

Should the filter be

fitted with a sensor to

detect the presence of

water (3), remove the

whole sensor from its

seat.

Remove the pre-filter by

unscrewing it.

Check that the new filter

has performance levels

that satisfy the needs of

the engine (e.g. by

comparing them with

the old one).

Damp the new filter seal with diesel or engine oil.

Hand screw the new filter into place until the seal gasket touches

the support, then lock by a further 3/4 of a turn.

Place the water presence sensor in its seat, taking care to couple

the threads correctly.

Loosen the bleeder screw (1) on the pre-filter support and activate

the hand pump (2) until the supply circuit is full. Ensure that any fuel

coming out is not dispersed into the environment.

Lock the bleeder screw tightly.

Start the engine and run it at idle for a few minutes to eliminate any

residual air.

Check the efficiency of the earthing connection of the filter support

(4).

Note: Should it be necessary to accelerate the bleeding phase, the

hand pump can be used during start-up.

Check exhaust pipe/s for damage

Visually check that the exhaust system is not blocked or damaged.

Make sure that there is no risk of dangerous fumes within the

machine. Contact the Manufacturer if necessary.

Impurity drainage or suction from fuel tank

Proceed taking into consideration the constraints of the tank’s

placement and structure.

The engines working in harsh environments and conditions and/or to

be refuelled from cans or barrels require even more accurate tank

cleaning.

Change auxiliary member belt

Please refer to the information provided for checking the belt tension.

Air filter replacement

Refer to the instructions provided for air filter cleaning.

Loading...

Loading...