MODEL: PFR2190

Adjustment wheel(C)

CAUTION:

It is advisable to test the depth on a scrap

workpiece to determine the required

depth for the application.

To determine depth of drive, first adjust

the air pressure and drive a test fastener.

Never exceed 120psi.

FIRING THE TOOL

(USING THE SELECTABLE TRIGGER)

The tool is equipped with a selectable trigger set in

the single sequential actuation mode(black trigger).

The selectable trigger(orange trigger) can also be

set for contact actuation mode.

SINGLE SEQUENTIAL ACTUATION MODE

Single sequential actuation provides the most

accurate fastener placement.

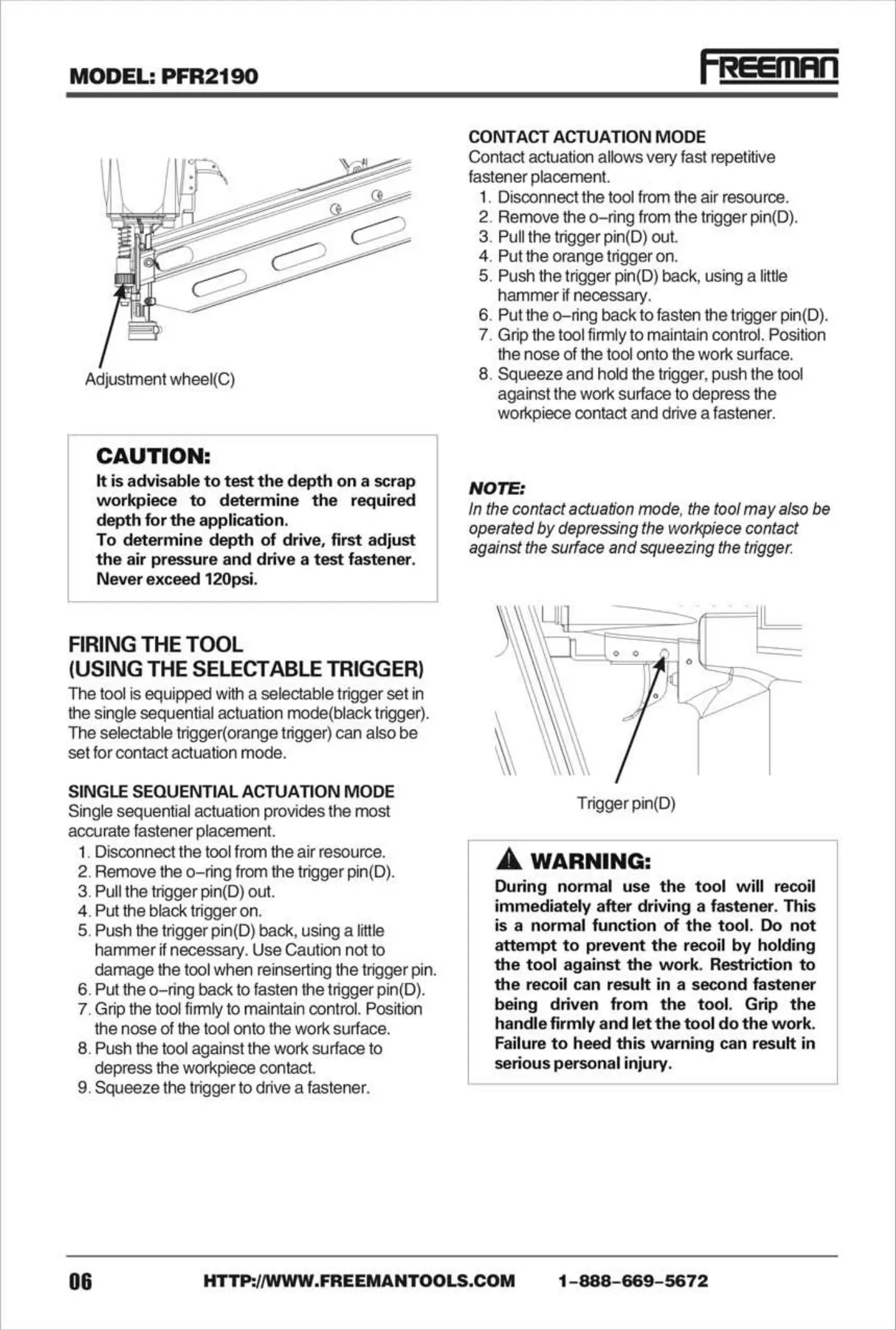

I. Disconnect the tool from the air resource.

2. Remove the O—ringfrom the trigger pin(D).

3. Pull the trigger pin(D)out.

4. Put the black trigger on.

5. Push the trigger pin(D) back, using a little

hammer if necessary. Use Caution not to

damage the tool when reinserting the trigger pin.

6. Put the O—ringback to fasten the trigger pin(D).

7. Grip the tool firmly to maintain control. Position

the nose of the tool onto the work surface.

8. Push the tool against the work surface to

depress the workpiece contact.

9. Squeeze the trigger to drive a fastener.

REErnnn

CONTACT ACTUATION MODE

Contact actuation allows very fast repetitive

fastener placement.

Disconnect the tool from the air resource.

1.

2. Remove the O—ringfrom the trigger pin(D).

3. Pull the trigger pin(D) out.

4. Put the orange trigger on.

5. Push the trigger pin(D) back, using a little

hammer if necessary.

6. Put the O—ringback to fasten the trigger pin(D).

7. Grip the tool firmly to maintain control. Position

the nose of the tool onto the work surface.

8. Squeeze and hold the trigger, push the tool

against the work surface to depress the

workpiece contact and drive a fastener.

NOTE:

In the contact actuaåon mode, the tool may also be

operated by depressing the wotkpiece contact

against the surface and squeezing the tngger.

Trigger pin(D)

A WARNING:

During normal use the tool will recoil

immediately after driving a fastener. This

is a normal function of the tool. Do not

attempt to prevent the recoil by holding

the tool against the work. Restriction to

the recoil can result in a second fastener

being driven from the tool. Grip the

handle firmly and let the tool do the work.

Failure to heed this warning can result in

serious personal injury.

MODEL: PFR2190

MAINTENANCE

A WARNING:

Any time inspection, maintenance, and

cleaning are done:

Disconnect the tool from the air resource.

• Empty the magazine completely.

ANTI-DUST

Each FREEMAN tool is packed with an anti—dust

cap on the air connector.

Keep the anti—dust cap cover the air connector

when the tool is not in use.

LUBRICATION

The tool is uniquely designed not to need daily

lubrication. But lubrication is required for best

performance after long periods use. Oil for

pneumatic fastening tools is added through the air

line connection and will lubricate intemal parts. Do

not use detergent oil or additives as these lubricants

will cause accelerated wear to the seals and

bumpers in the tool, resulting in poor tool

performance and frequent tool maintenance.

CAUTION:

Lubricate tool only with specified

lubricants.

CLEARING

Avoid using solvents when deaning plastic parts.

Most plastics are susceptible to damage from

various types of commercial solvents and maybe

damaged by their use. Use clean cloths to remove

dirt. dust , oil, grease, etc.

A WARNING:

Do not at any time let brake fluids,

gasoline, petroleum—based products,

penetration oils, ect come in contact

with plastic parts. Chemicals can damage,

weaken or destroy plastic which may

result in serious personal injury.

RE€rnan

COLD WEATHER OPERATION

For cold weather operation, near and below freezing,

the moisture in the air line may freeze and prevent

tool operation. We recommend the use of air tool

lubricant or permanent antifreeze (ethylene glycol) as

a cold weather lubricant.

CAUTION:

Do not store tools in a cold weather

environment to prevent frost or ice

formation on the tool's operating valves

and mechanisms that could cause tool

failure.

06

HTTP://WWW.FREEMANTOOLS.COM

1-888-669-5672

HTTP://WWW.FREEMANTOOLS.COM

1-888-669-5672

07

Loading...

Loading...