42–00 Safety Precautions

Safety Precautions in this section apply to all

procedures within this group.

DANGER

When working on the vehicle, shut down the en-

gine, set the parking brake, and chock the tires.

Before working under the vehicle, always place

jack stands under the frame rails to ensure the

vehicle cannot drop. Failure to follow these steps

could result in serious personal injury or death.

42–01 Brake System Valves

Inspecting

1. Clean the valves exterior and inspect them for

corrosion and damage.

2. Inspect the air lines connected to the valves for

signs of wear or damage. Replace the lines as

needed.

3. Check the valves for leakage.

3.1 Apply the service brakes and hold them

on a full line pressure of at least 80 psi

(552 kPa).

3.2 Check the air line fittings for leaks; tighten

or replace the fittings as needed.

3.3 Coat the exhaust port and body of the

valves with soapy water, and check for

leakage. Leakage is excessive if it pro-

duces a 1-inch (25-mm) bubble within 5

seconds.

If a brake valve does not function as de-

scribed above, or if leakage is excessive,

replace it with a new or remanufactured

unit. Repeat the leakage checks before

placing the vehicle in service.

42–02 Air Dryer Checking

IMPORTANT: Review the warranty policy before

performing any intrusive maintenance proce-

dures. An extended warranty may be voided if

intrusive maintenance is performed during this

period.

Because no two vehicles operate under identical

conditions, maintenance and maintenance intervals

will vary. Experience is a valuable guide in determin-

ing the best maintenance interval for any one particu-

lar operation.

Every 12 months:

1. Check for moisture in the air brake system by

opening reservoir drain valves and checking for

presence of water. If moisture is present, the

desiccant cartridge may require replacement;

however, the following conditions can also cause

water accumulation and should be considered

before replacing the desiccant:

• An outside air source has been used to

charge the system. This air did not pass

through the drying bed.

• Air usage is exceptionally high and not nor-

mal. This may be due to high air system

leakage.

• In areas where more than a 30-degree

range of temperature occurs in one day,

small amounts of water can temporarily

accumulate in the air brake system due to

condensation. Under these conditions, the

presence of small amounts of moisture is

normal.

NOTE: A small amount of oil in the system is

normal and should not be considered as a rea-

son to replace the desiccant cartridge. Some oil

at the dryer exhaust is normal.

2. Visually check for physical damage, such as

chaffed or broken air and electrical lines and bro-

ken or missing parts.

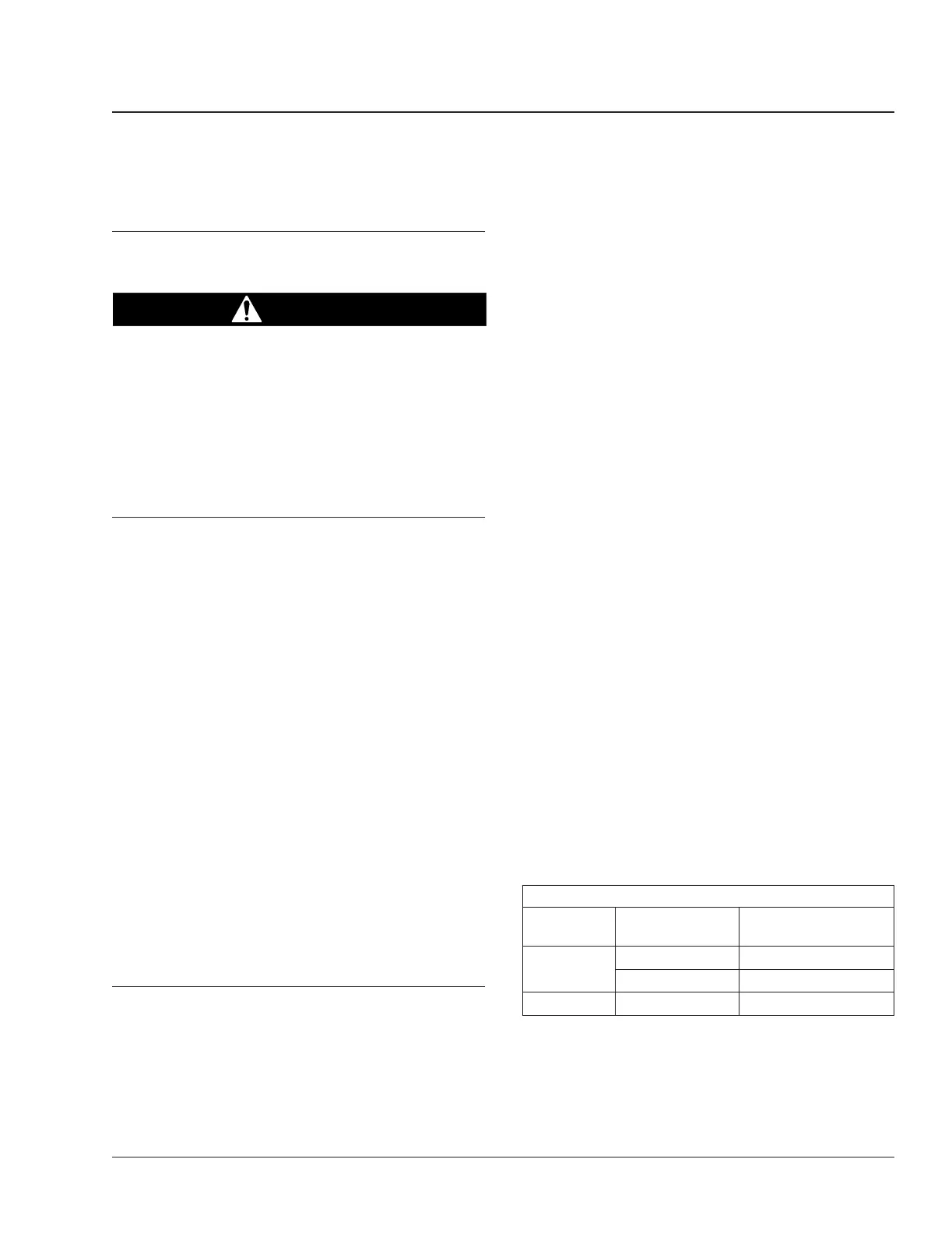

3. Check the mounting bolts for tightness. See

Table 1 for torque values.

Torque Values

Vendor Size

Torque:

lbf·ft (N·m)

Bendix

Grade 5, 3/8–16 28 (38)

Grade 5, 5/8–11 135 (183)

Haldex 1/2–13 45 to 55 (61 to 75)

Table 1, Torque Values

4. Perform the operational and leakage tests listed

below.

Brakes 42

Recreational Vehicle Chassis Maintenance Manual, July 2018 42/1

Loading...

Loading...