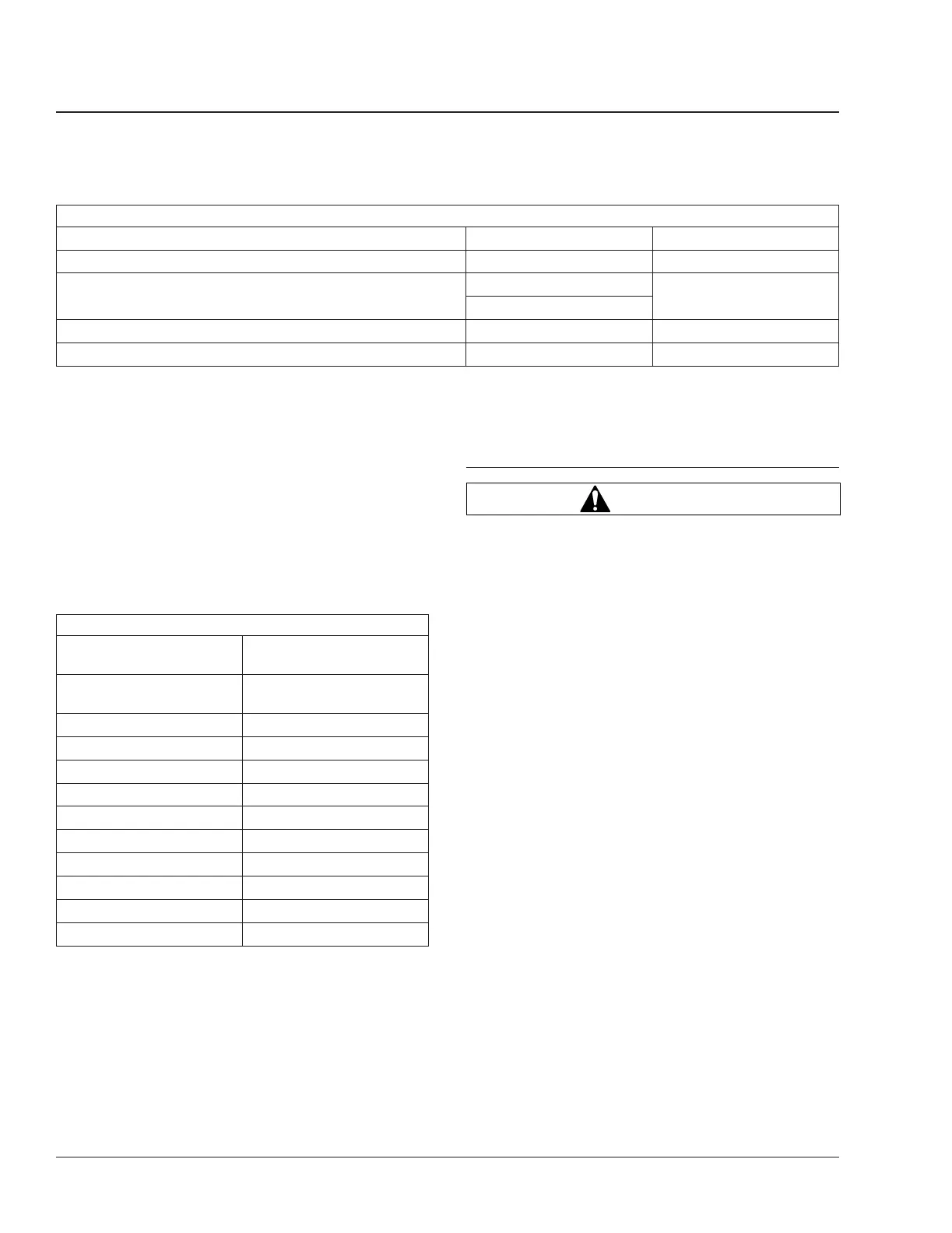

Suspension Torque Specifications (lubricated threads)

Description Size Torque: lbf·ft (N·m)

Equalizing Beam Center Bushing Locknut 3/4–16 150 to 200 (203 to 271)

Equalizing Beam Front Bushing Locknut

1-1/8–12

600 to 700 (814 to 949)

1-1/4–12

Control Rod Ball Stud Locknut 1-1/8–12 550 to 650 (746 to 881)

Control and Torque Rod Mounting Locknuts 5/8–18 110 to 150 (149 to 203)

Table 1, Suspension Torque Specifications (lubricated threads)

NOTE: Height control valves control all front and

rear suspension air springs. Check for air leaks

by applying a soapy solution. Then, check for

bubbles at all air connections and fittings.

5. Check the ride height of the air suspension by

measuring the distance from the center of the

lower shock bolt to the bottom of the frame rail.

See

Fig. 1. See Table 2 for height control valve

adjustment measurements. If ride height is incor-

rect, adjust the air suspension.

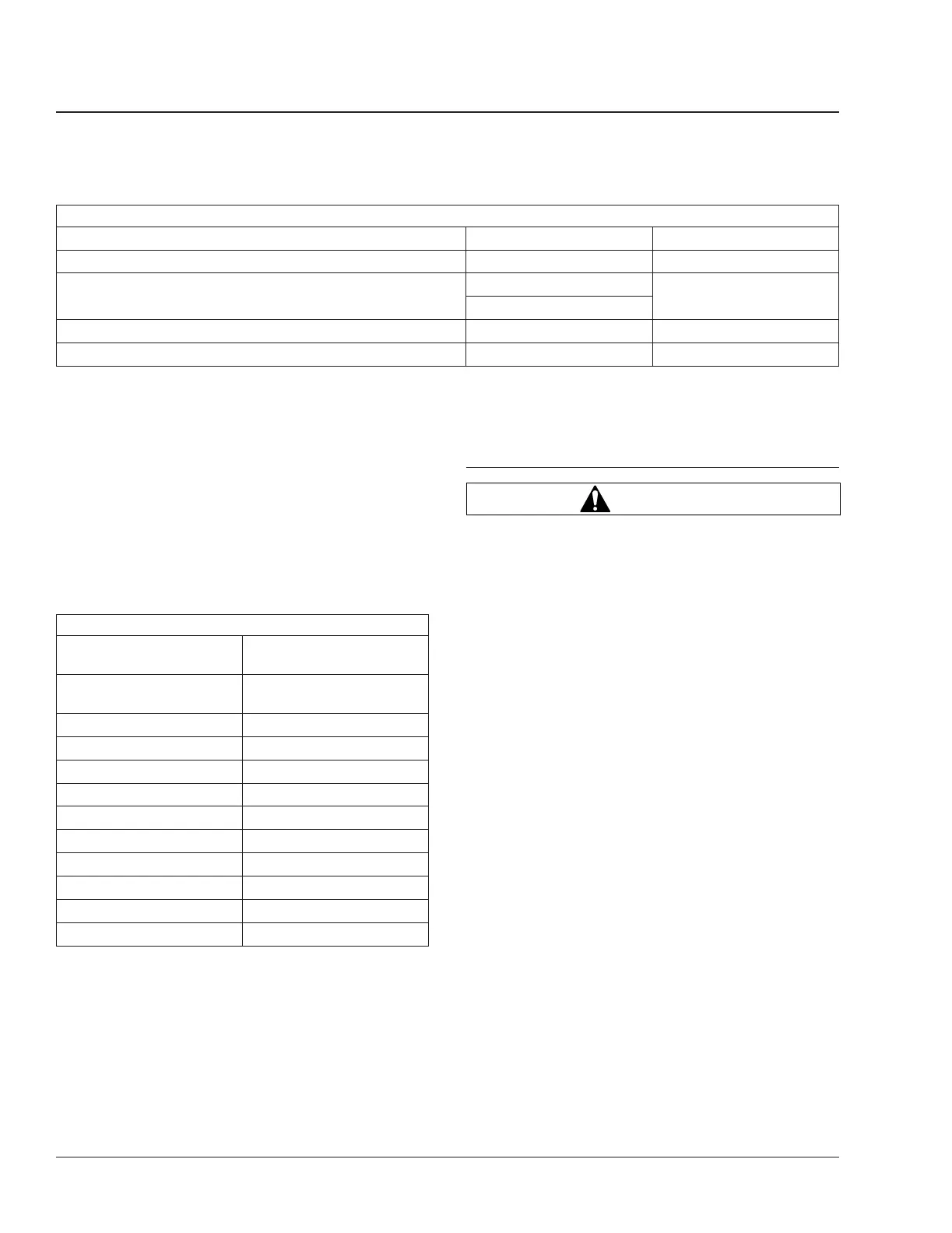

Height Control Valve Adjustment Measurements

Suspension

Measurement

Inches ±1/4 (mm ±6)

AS120 (front)

10 (254) or

10-1/2 (267)

*

AS140 (front) 11 (279)

IFS114 (front) 17-1/2 (445)

IFS ZF (front) 15-3/4 (400)

ADL-RS17/19/21 10-1/4 (260)

AD200-RS17/19 9-3/4 (248)

AD200-RS15 9-3/8 (238)

ADTB280 (rear) 17-1/4 (438)

Airliner 15k (rear) 8-3/4 (222)

AD123 (rear) 18 (457)

ADL123 (rear) 11 (279)

*

Some vehicles have a different shock location. When this is the case, the

vehicle will have a 55 degree wheel cut. Ride height for these vehicles

should be set at 10-1/2 inches (267 mm).

Table 2, Height Control Valve Adjustment

Measurements

32–03 Neway Suspension

Inspection

WARNING

Inspect the components and check their operation

as described below. Failure to perform these in-

spections and checks could result in separation of

worn suspension components and loss of vehicle

control, possibly causing personal injury or death,

or property damage.

1. Chock the front or the rear tires. Working at the

front of the vehicle or at the rear of the vehicle,

raise the vehicle so that the tires just clear the

ground and the suspension is fully extended.

Place safety stands under the vehicle frame.

2. Squeeze all air springs to check for complete

deflation. It may take ten minutes for the pres-

sure to bleed down from the air spring. See

Fig. 2. If any air springs remain partially or fully

inflated, see Group 32 of the Recreational Ve-

hicle Chassis Workshop Manual, or take the ve-

hicle to an authorized Freightliner dealer. Inspect

the air springs for cracks, tears, or other dam-

age.

3. Inspect each air spring for wear at the pedestal

connection. Inspect for leaks at the upper and

lower pedestal connections using a soapy solu-

tion. Replace any worn air springs; for instruc-

tions, see Group 32 of the Recreational Vehicle

Chassis Workshop Manual, or take the vehicle to

an authorized Freightliner dealer.

4. Inspect the bolts and nuts at the pivot connec-

tions, the transverse beam connections, and the

axle connections to ensure they are tightened to

the correct torque specification.

Suspension32

Recreational Vehicle Chassis Maintenance Manual, June 201532/2

Loading...

Loading...