related to lubricant changes that are governed by

climatic conditions and magnetic plug maintenance.

Change lubricant type and viscosity as climatic tem-

peratures demand, regardless of vehicle mileage or

established change schedule.

The normal operating temperature of compounded

lubricants during the summer season is about 160 to

220°F (71 to 104°C). The chemicals and additives

that give these lubricants increased load carrying ca-

pacity oxidize faster at temperatures above 220°F

(104°C), contributing to more rapid lubricant deterio-

ration. For this reason, lubricants of this type that

operate continuously at high temperatures must be

changed more frequently.

NOTICE

Failure to change the axle lubricant at more fre-

quent intervals, when adverse operating condi-

tions require, could result in axle damage.

Axle Draining

1. Park the vehicle on a level surface, shut down

the engine, and set the parking brake. Chock the

tires.

2. Clean the fill plug and the area around it. Re-

move the plug from the oil fill hole. See

Fig. 1.

CAUTION

Be careful when draining the axle oil. It may be

very hot, and could cause personal injury if it con-

tacts the skin.

3. Remove the plug at the bottom of the housing

and drain the lubricant while the unit is warm.

Allow enough time for all the old lubricant to

drain completely.

4. Clean the drain plug. For magnetic drain plugs, a

piece of key stock or any other convenient steel

slug may be used to short the two magnetic

poles and divert the magnetic field.

NOTE: Meritor recommends using magnetic

plugs with elements having a minimum pickup

capacity of two pounds (one kilogram) of low-

carbon steel in plate or bar form. Magnets will

rapidly lose effectiveness as collected material

bridges the gap between the two poles. Clean

or change the plugs before this occurs. It may

be necessary to clean or change the plugs one

or more times between lubrication change inter-

vals.

5. After cleaning the drain plug, install and tighten

the plug 30 lbf·ft (41 N·m) for Detroit axles or 35

lbf·ft (47 N·m) for Meritor axles.

Axle Filling

1. With the vehicle on a level surface, fill the axle

housings to the bottom of the oil fill hole (in the

carrier or housing) with recommended lubricant;

see

Table 2. Refer to Table 3 for Detroit drive

axle lubricant capacities or

Table 4 for Meritor

drive axle lubricant capacities.

NOTE: Some Meritor axles have a small tapped

and plugged hole located below the housing oil

fill hole. This smaller hole is for the lubricant

temperature sensor only and must not be used

as a fill or level hole.

2. Install the fill hole plug and tighten it 30 lbf·ft (41

N·m) for Detroit axles or 35 lbf·ft (47 N·m) for

Meritor axles.

3. After filling the carrier and housing assembly with

lubricant, drive the vehicle unloaded for one or

two miles (two or three kilometers) at speeds not

to exceed 25 mph (40 km/h) to thoroughly circu-

late the lubricant throughout the assembly.

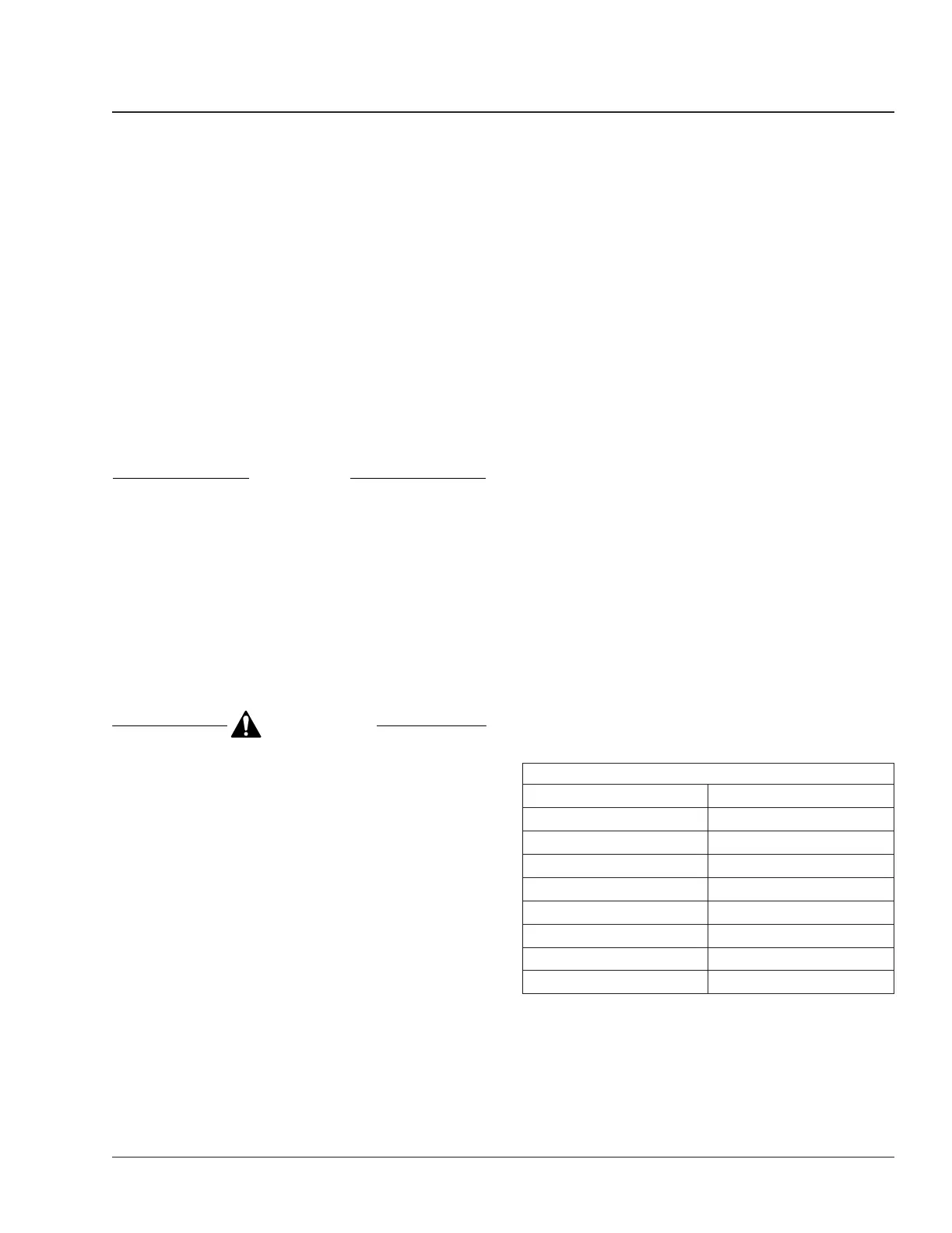

Detroit Drive Axle Lubricant Capacities

Axle Model

*

Capacity

†

: pints (L)

ARS–13.0–2 15 (7)

ARS–15.0–2 15 (7)

ARS–17.5–2 15 (7)

ARS–19.0–2 15 (7)

ARS–20.0–2 15 (7)

ARS–21.0–2 15 (7)

ARS–21.0–4 23 (11)

ARS–23.0–4 23 (11)

*

Model code may have a "D" in the prefix (for example, DA–RS–13.0–2).

†

Quantities listed are approximate and include 1 pint (0.5 liter) for each

wheel end and with the drive pinion at 3 degrees.

Table 3, Detroit Drive Axle Lubricant Capacities

Rear Axle 35

Recreational Vehicle Chassis Maintenance Manual, June 2015 35/3

Loading...

Loading...