41–00 Safety Precautions

Safety Precautions in this section apply to all

procedures within this group.

DANGER

When working on the vehicle, shut down the en-

gine, set the parking brake, and chock the tires.

Before working under the vehicle, always place

jack stands under the frame rails to ensure the

vehicle cannot drop. Failure to follow these steps

could result in serious personal injury or death.

41–01 Driveline Inspection and

Lubrication

Inspection

Before lubricating the driveline U-joints and slip-

joints, make the following checks.

1. Check that the yoke-strap capscrews are tight-

ened 50 to 60 lbf·ft (68 to 81 N·m).

NOTICE

Do not overtighten the yoke-strap capscrews, due

to the extreme load occurring at high-speed rota-

tion. A loose or broken capscrew at any point in

the driveline weakens the driveline connection,

which could eventually result in serious vehicle

damage.

2. Check the slip-joints for spline wear by trying to

bend the sleeve-yoke and splined shaft back and

forth. If looseness is greater than 0.007 inch

(0.18 mm), replace both the sleeve-yoke and the

splined shaft.

3. Check the driveshaft for missing balance

weights, and for debris buildup. Remove any

buildup. If any balance weights are missing, re-

move the driveshaft and have it balanced. For

instructions, see Group 41 of the vehicle Work-

shop Manual, or take the vehicle to an autho-

rized Freightliner dealer.

4. Check that the yoke plug is not loose or missing.

Replace the yoke plug if needed. If the yoke plug

is missing, the splined shaft may be hitting the

yoke plug and knocking it out; check the drive-

shaft for proper length.

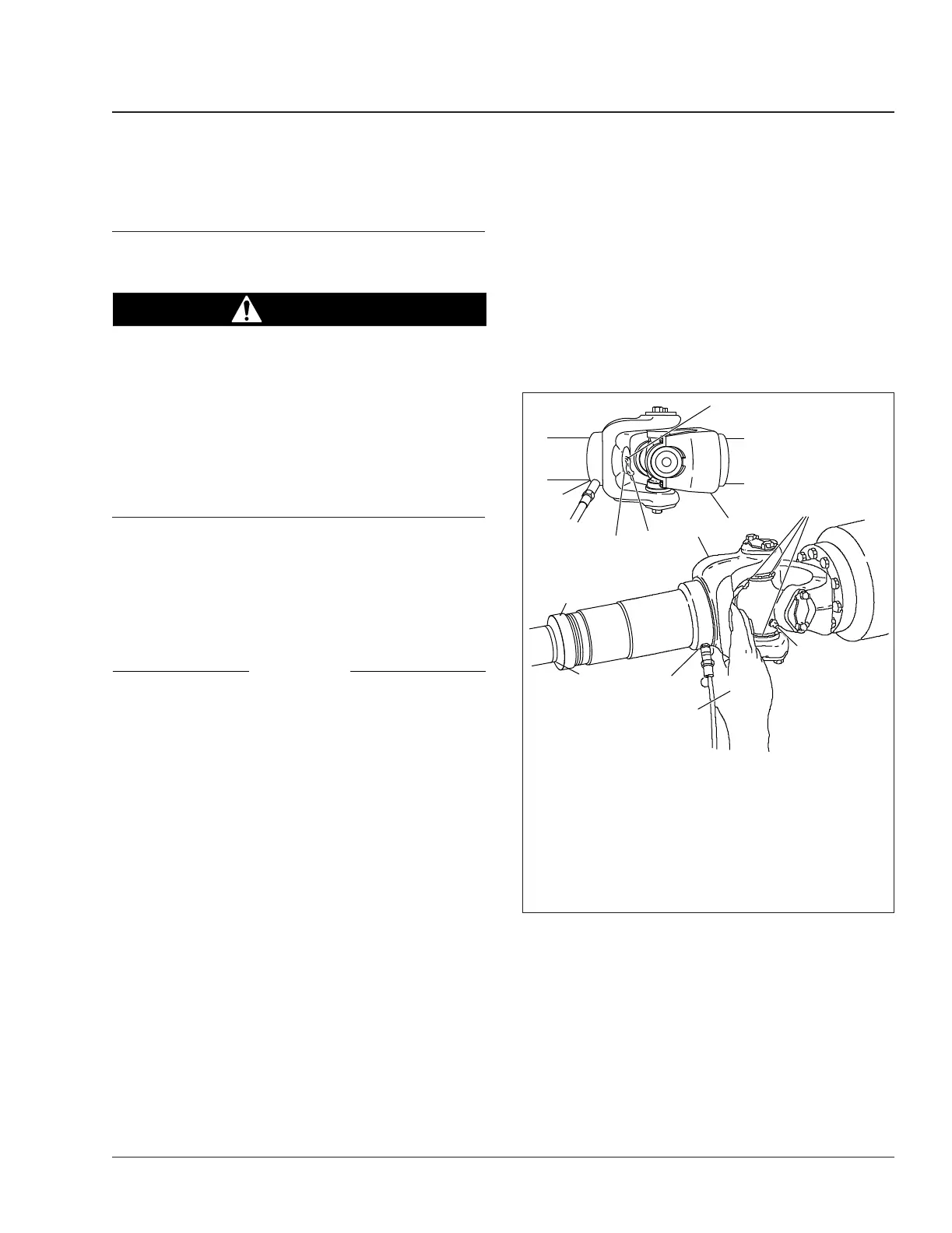

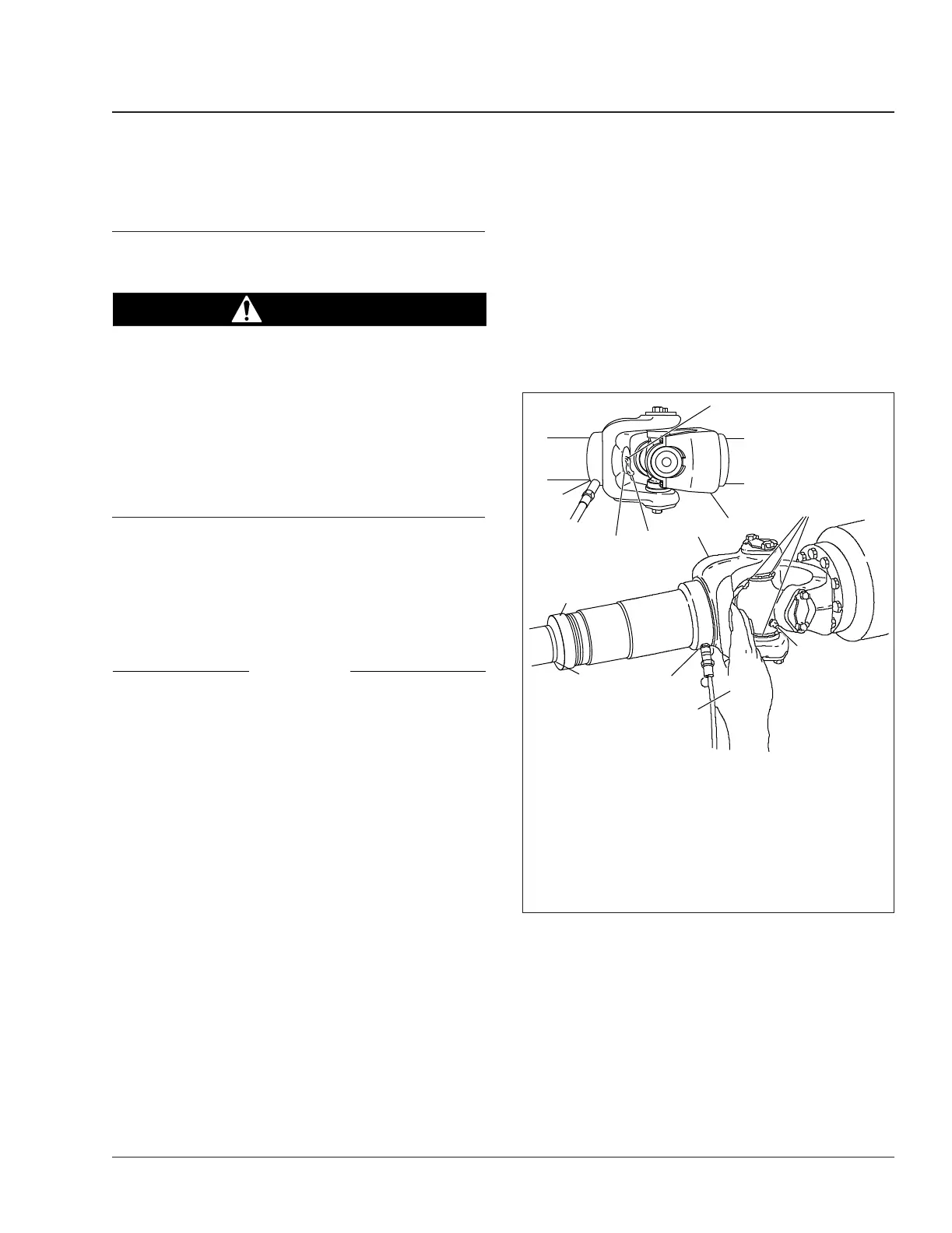

U-Joint Lubrication

1. Wipe all old grease and dirt from each U-joint

grease fitting.

2. Use a hand-type grease gun, or a high-pressure

gun with a low-pressure adaptor, to lubricate the

U-joints. See

Fig. 1.

NOTE: If a low-pressure adaptor is not used

with the high-pressure gun, the U-joints may not

receive enough lubricant.

3. Using lithium 12-hydroxy stearate grease (NLGI

grade 1 or 2, with EP additives), lubricate until

new grease can be seen at all four U-joint seals.

f410050a10/07/2016

1

1

2

3

3

3

4

5

6

7

8

A

A. After grease appears, cover the pressure-relief hole

while continuing to lubricate.

1. Slip-Joint Grease

Fitting (with grease

gun attached)

2. Yoke Plug

3. Grease

4. Half-Round Yoke

5. Yoke Plug Pressure-

Relief-Hole

6. Slip-Joint Seal

7. Full-Round Yoke

8. U-Joint Grease Fitting

Fig. 1, Slip-Joint and U-Joint Lubricating

Driveline 41

Recreational Vehicle Chassis Maintenance Manual, June 2015 41/1

Loading...

Loading...