tilecabinet.If backof rangewill not beflushwith

the wall (thelocationoftheoutletmaynotallowthe

rangeto bepositionedagainstthewall),drawa lineon

thefloorwherethebackedgeoftherangewill be.Now

installanti-tipbrackets(see"Anti-tipBrackets

Installation",page10).

tf rangewill not beinstalledagainstacabinet,

moverangeintofinalposition.Drawalineonthefloor

alongbothsidesoftherange,tf backof rangewill not

beflushwith the wall (thelocationoftheoutletmay

notallowtherangeto bepositionedagainstthewall),

drawalineonthefloorwherethebackedgeof the

rangewillbe.Nowinstallanti-tipbrackets(see"Anti-tip

BracketsInstallation",page10).

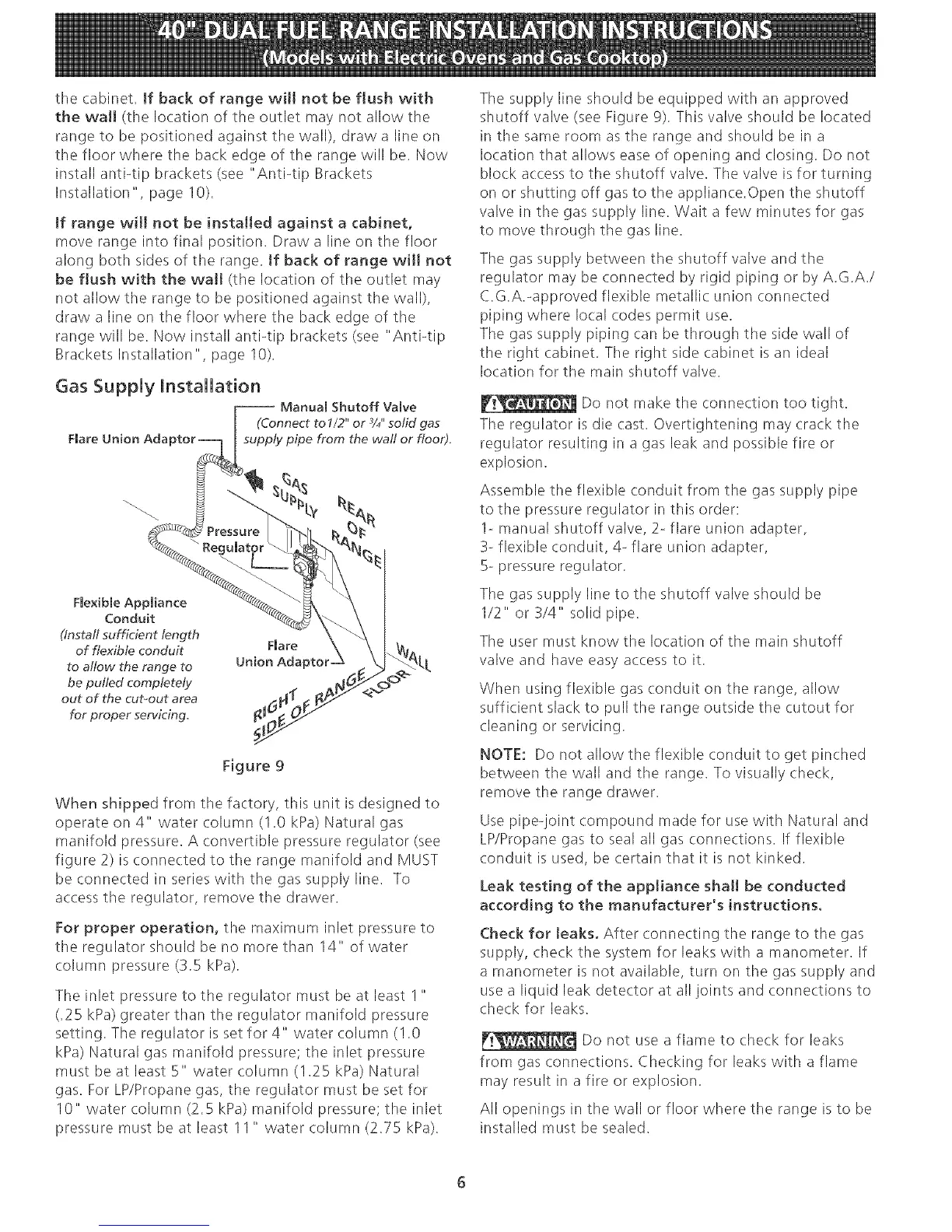

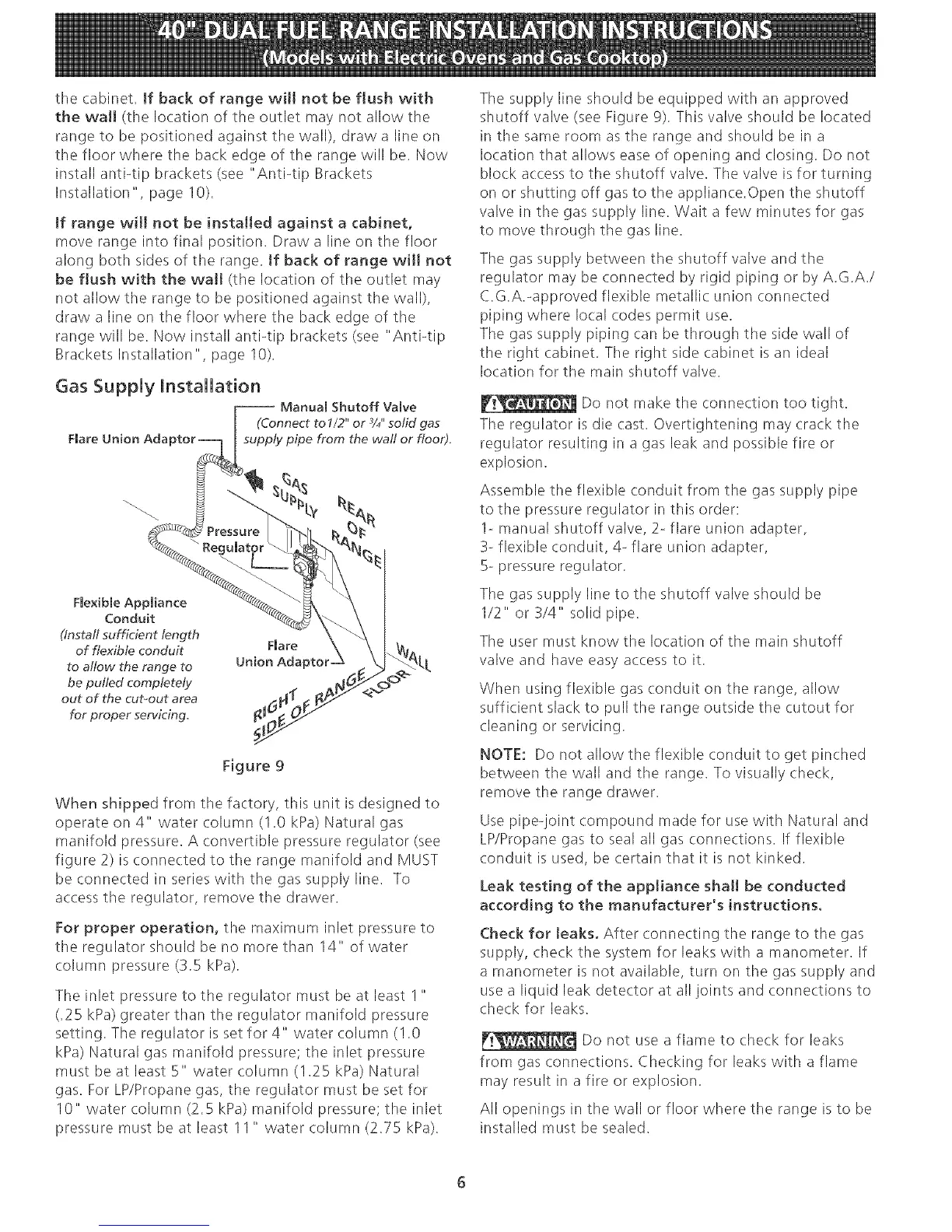

Figure9

Whenshippedfromthefactory,thisunitisdesignedto

operateon4" watercolumn(1.0kPa)Naturalgas

manifoldpressure.Aconvertiblepressureregulator(see

figure2)isconnectedtotherangemanifoldandMUST

beconnectedinserieswiththegassupplyline. To

accesstheregulator,removethedrawer.

Forproperoperation,themaximuminletpressureto

theregulatorshouldbenomorethan14"ofwater

columnpressure(3.5kPa).

Theinletpressureto theregulatormustbeat leastI "

(.25kPa)greaterthantheregulatormanifoldpressure

setting.Theregulatorissetfor4" watercolumn(I.0

kPa)Naturalgasmanifoldpressure;theinletpressure

mustbeatleast5" watercolumn(1.25kPa)Natural

gas.ForLP/Propanegas,theregulatormustbesetfor

10"watercolumn(2.5kPa)manifoldpressure;theinlet

pressuremustbeatleast11" watercolumn(2.75kPa).

Thesupplylineshouldbeequippedwithanapproved

shutoffvalve(seeFigure9).Thisvalveshouldbelocated

inthesameroomastherangeandshouldbeina

locationthatallowseaseofopeningandclosing.Donot

blockaccesstotheshutoffvalve.Thevalveisforturning

onorshuttingoff gastotheappliance.Opentheshutoff

valveinthegassupplyline.Waitafewminutesforgas

tomovethroughthegasline.

Thegassupplybetweentheshutoffvalveandthe

regulatormaybeconnectedbyrigidpipingor byA.G.A./

C.G.A.-approvedflexiblemetallicunionconnected

pipingwherelocalcodespermituse.

Thegassupplypipingcanbethroughthesidewallof

therightcabinet.Therightsidecabinetisanideal

locationforthemainshutoffvalve.

Donotmaketheconnectiontootight.

Theregulatorisdiecast.Overtighteningmaycrackthe

regulatorresultinginagasleakandpossiblefireor

explosion.

Assembletheflexibleconduitfromthegassupplypipe

tothepressureregulatorinthisorder:

1-manualshutoffvalve,2-flareunionadapter,

3-flexibleconduit,4-flareunionadapter,

5-pressureregulator.

Thegassupplylinetotheshutoffvalveshouldbe

1/2"or3/4"solidpipe.

Theusermustknowthelocationofthemainshutoff

valveandhaveeasyaccessto it.

Whenusingflexiblegasconduitontherange,allow

sufficientslackto pulltherangeoutsidethecutoutfor

cleaningorservicing.

NOTE:Donotallowtheflexibleconduittogetpinched

betweenthewallandtherange.Tovisuallycheck,

removetherangedrawer.

Usepipe-jointcompoundmadefor usewithNaturaland

LP/Propanegastosealallgasconnections.Ifflexible

conduitisused, be certain that it is not kinked.

Leak testing of the appliance shah be conducted

according to the manufacturer's instructions.

Check for Jeaks. After connecting the range to the gas

supply, check the system for leaks with a manometer. If

a manometer is not available, turn on the gas supply and

use a liquid leak detector at all joints and connections to

check for leaks.

Do not use a flame to check for leaks

from gas connections. Checking for leaks with a flame

may result in a fire or explosion.

All openings in the wall or floor where the range is to be

installed must be sealed.

Loading...

Loading...