5CS2004OM (rev 00 07/2020) 17Operation

NOTE: Lower pressure settings will result in

less spray drift.

Example:

Assume tractor speed is determined to be 4

mph, nozzles are gray (TFVP3), and desired

GPA is 20 GPA. The calibration charts shows

that you should set sprayer’s pressure at about

20 psi in order to apply 20 GPA.

NOTE: Optimum spray performance is achieved

between 20-25 psi. When shutting off outer tips,

use the regulator valve to adjust your boom

pressure accordingly.

Boomless Calibration

Right and Left Nozzles: 1/4XP10R

Center Nozzle: TF-VP3

Drop Size: XC

BOOMLESS CALIBRATION CHART FOR 24”

HEIGHT

PSI

Cap. 3

Nozzle

GPM

Spray

Width

“ft”

GPA

4 MPH 6 MPH 8 MPH 10 MPH

20 1.8 23 10.5 7.1 5.1 4.2

30 2.3 25 11.2 6.5 5.6 4.5

40 2.6 28 11.9 7.9 6.0 4.8

BOOMLESS CALIBRATION CHART FOR 36”

HEIGHT

PSI

Cap. 3

Nozzle

GPM

Spray

Width

“ft”

GPA

4 MPH 6 MPH 8 MPH 10 MPH

20 1.8 25 10.1 6.6 5.0 3.8

30 2.3 28 10.4 6.9 5.2 4.1

40 2.6 30 10.7 7.2 5.4 4.3

Adjusting the Sprayer Pressure

NOTE: All calibration needs to be done with

clean water.

Once correct pressure setting has been deter-

mined, the sprayer must be adjusted to that

pressure setting. Before adjusting sprayer’s

pressure, it is important to set tractor

rpm at rate that was used to determine tractor

speed.

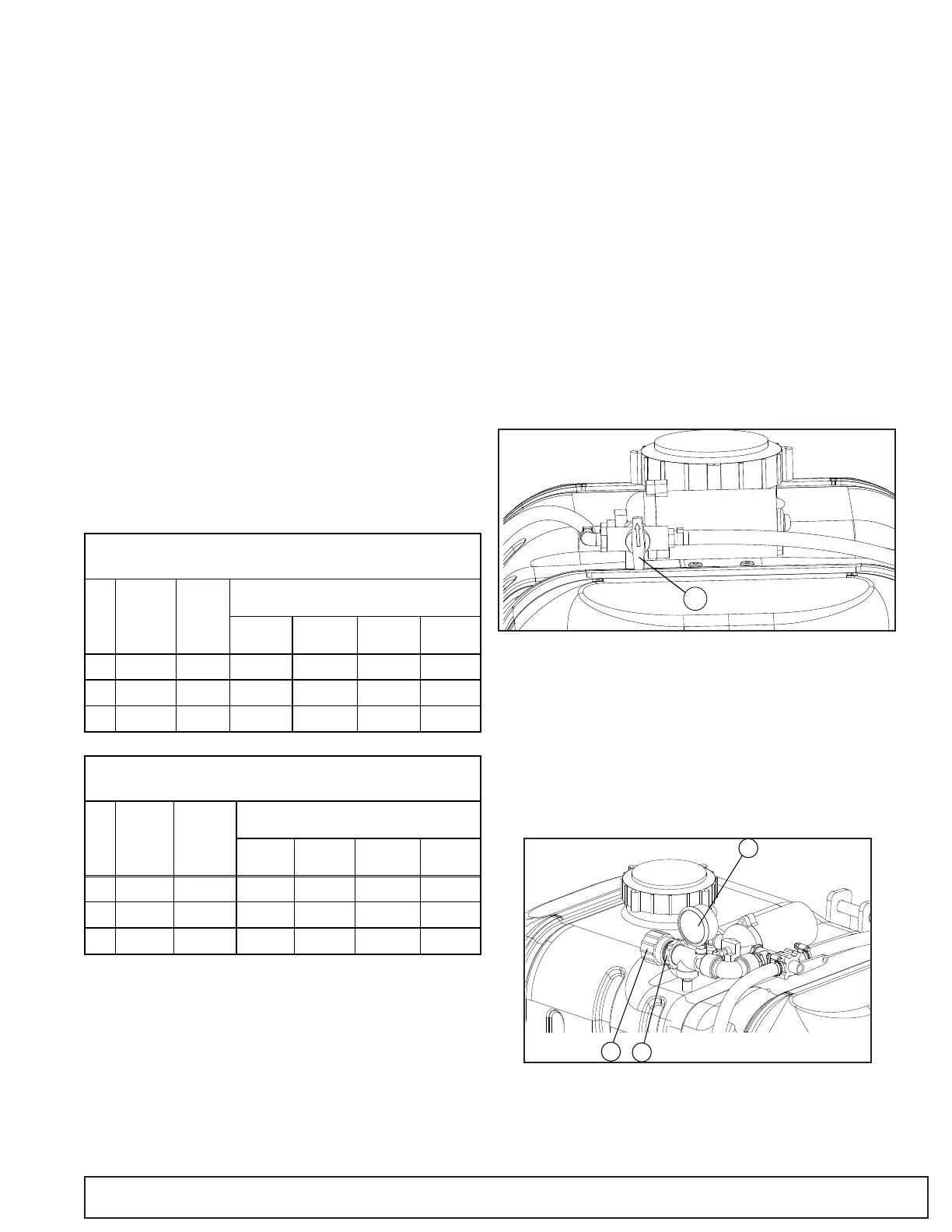

2.2 gpm pump

Although the pressure can be adjusted by par-

tially opening the control valve (A), it is

recommended that the valve be placed in the

full open position.

• The 10 ft boom is equipped with the TF-VP3

tips and sprays at approximately 20 PSI

through the boom when the valve is in open

position.

• For calibration purposes, adjust your speed

for proper coverage.

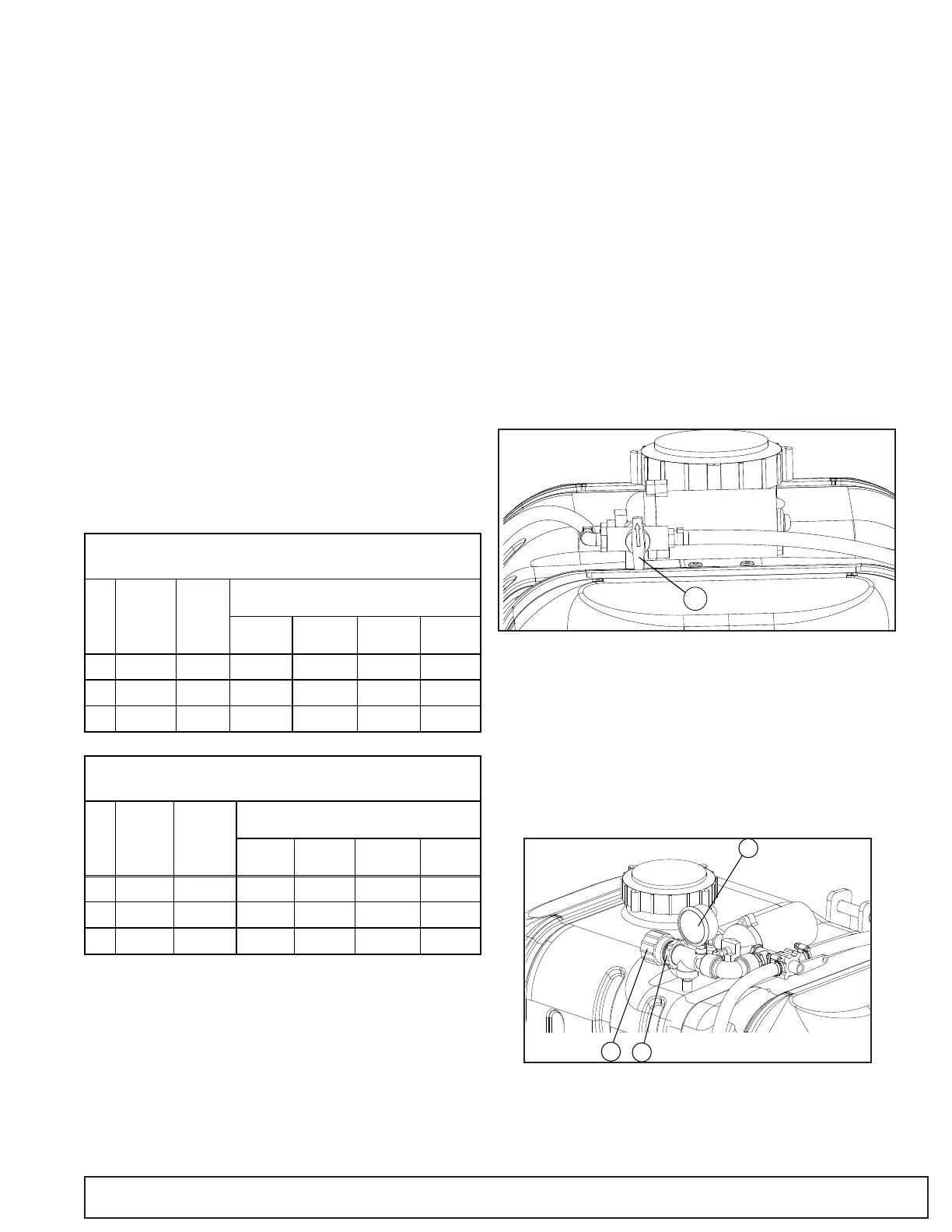

4.0 gpm pump

1. Loosen lock ring (B) and adjust knob (C) to

desired pressure. Pressure is displayed on

gauge (D).

2. Once desired pressure is achieved tighten

lock ring (B).

3. Sprayer is now calibrated.

A

C

Loading...

Loading...