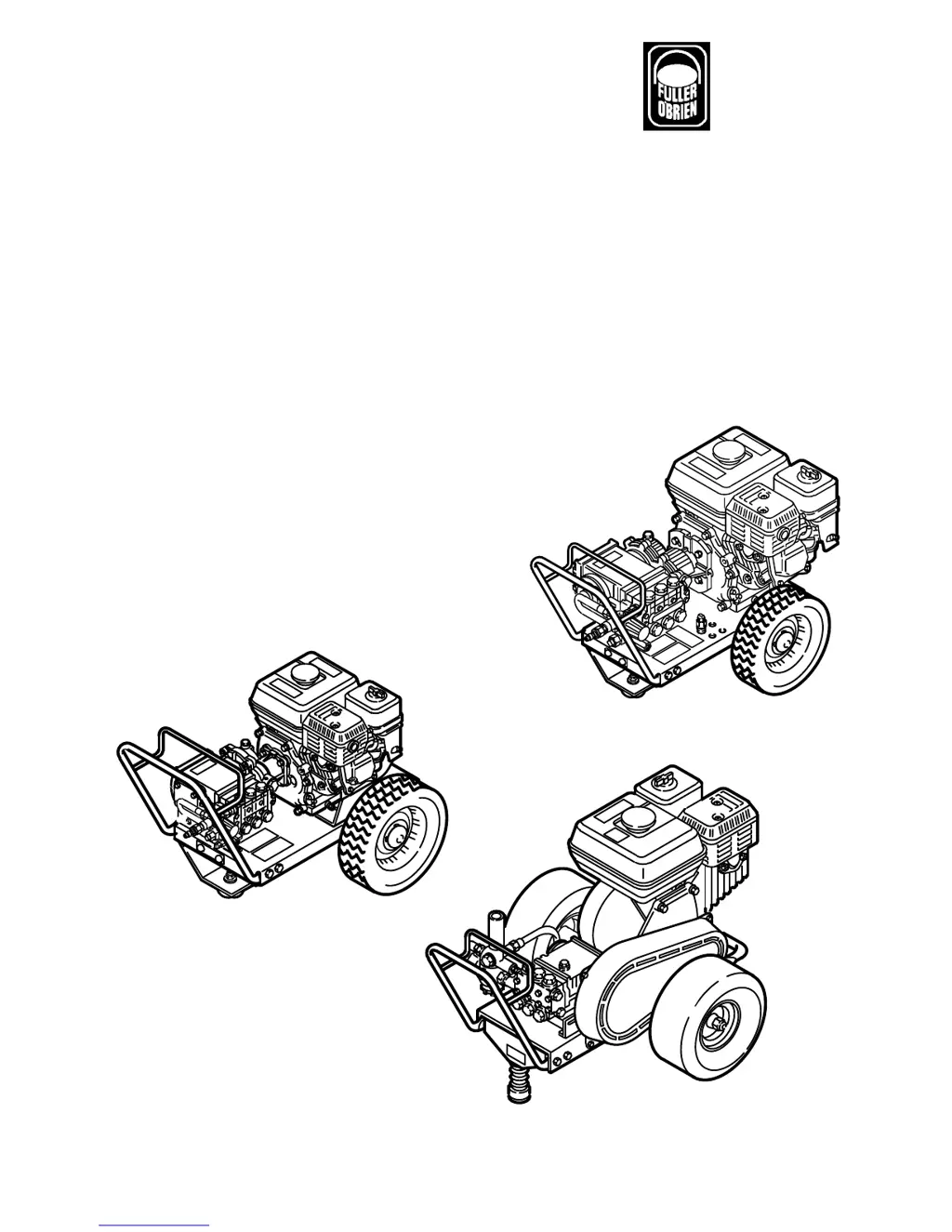

How to fix a FULLER O’BRIEN Pressure Washer engine that won't start?

- JJessica PooleAug 15, 2025

If your FULLER O’BRIEN Pressure Washer engine won't start, first, ensure there's gasoline in the fuel tank and the fuel shut-off valve is open. If the tank is full, check the oil level and add more if it's low. Make sure the Start/Stop switch is in the Start position. Also, consider draining the fuel tank and carburetor if there's water in the gasoline or if the fuel is old, and use new fuel and dry the spark plug. If the engine is flooded, clear out the gas by opening the choke and cranking the engine several times. Also, clean or replace a dirty air filter or spark plug. Finally, ensure the spray gun is not closed by triggering it.