IOM GMI 2M & 2ML Nov 2010.doc

32

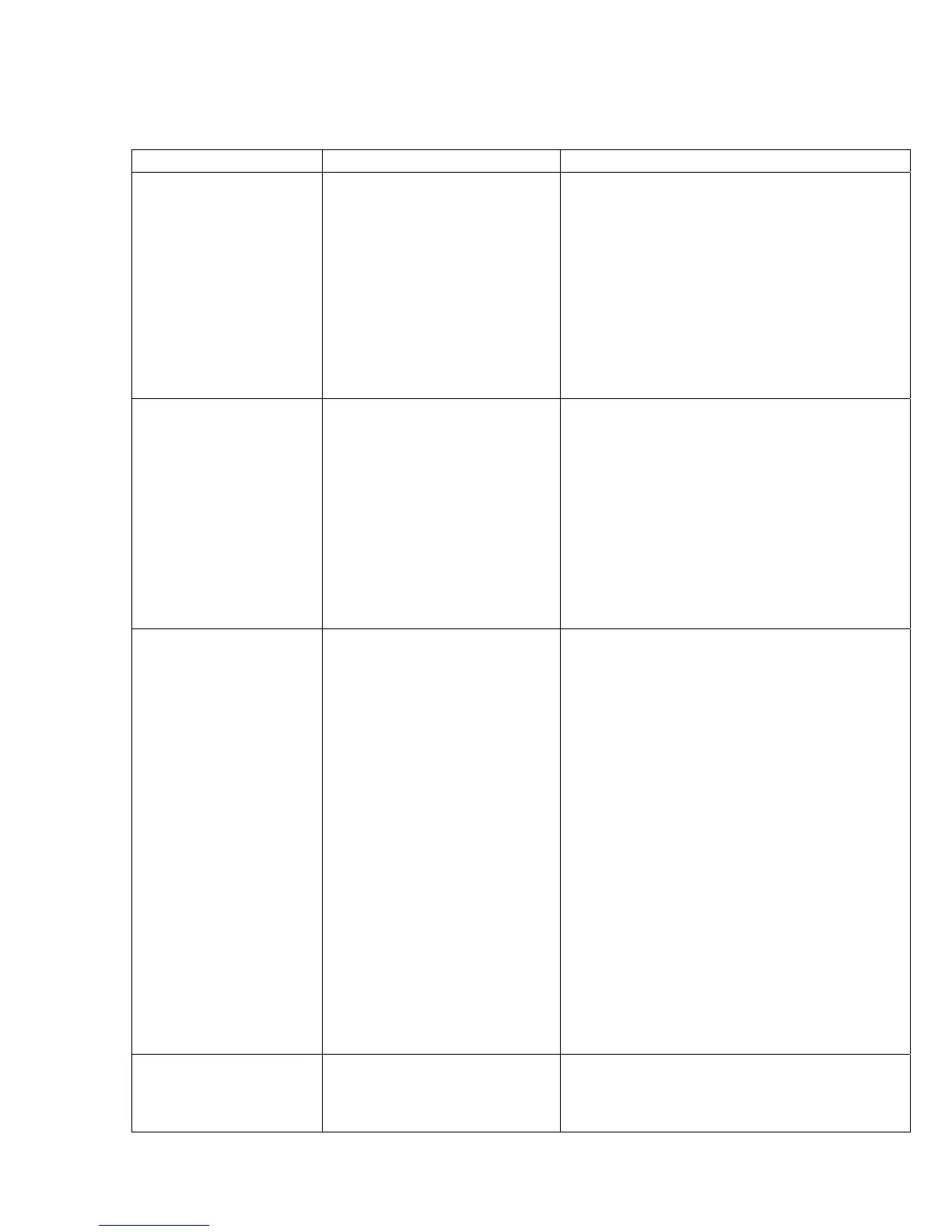

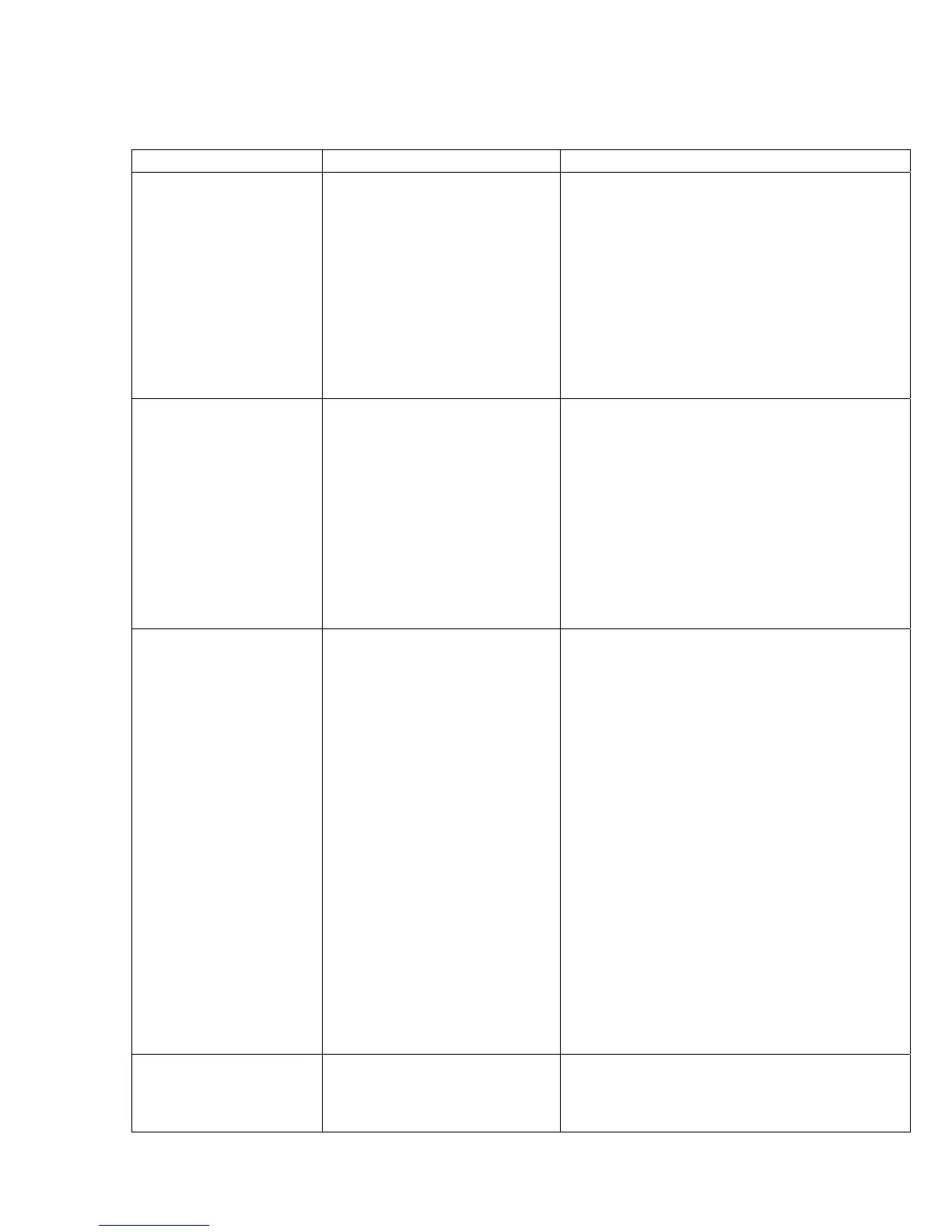

4.2 Troubleshooting

Fault Cause Corrective Action

♦ Blower does not start ♦ Power not supplied to the unit.

♦ Safety loop open.

♦ None of the above

♦ Ensure power switch is on.

♦ Check both fuses on the power and the supply

sides.

♦ Ensure BMS (if connected) calls for heat.

♦ Ensure high temperature limit switch is closed.

♦ Ensure maximum operating temperature switch

is closed.

♦ Ensure low gas pressure switch is closed.

♦ See page 20 of the Riello catalogue for burner

controller trouble shooting.

♦ Unit does not start ♦ Blower does not run.

♦ Air pressure switch installed

on the housing is open.

♦ Gas pressure switch is open.

♦ No ignition.

♦ See above

♦ Adjust switch.

♦ Replace switch (if defective).

♦ Adjust the switch.

♦ Replace switch (if defective).

♦ See page 20 of the Riello catalogue for burner

trouble controller trouble shooting

♦ Pilot flame failure ♦ Pilot gas valve not opened

♦ No ignition

♦ Check the electrical connections to ensure they

are all securely connected (see the schematic

wiring diagram for terminals).

♦ Check the two, safety shut off valves. Replace

if defective.

♦ Check the electrical connections to ensure they

are all securely connected (see “Factory Wiring

Diagram” on page 15 of the Riello catalogue)

for terminals.

♦ Check the flame rod to ensure it is clean and

free of any sedimentation. Clean flame rod if

necessary.

♦ Check the flame rod for any cracks or other

defects. Replace flame rod if necessary.

♦ Measure gas pressure in the pilot line at the exit

test port of the second safety valve (downstream

of the regulator). Ensure it is within the

specified 2”-5” wc. If pressure is not available

check both safety shut off valves and the

pressure regulator. Replace any defective

component, if necessary.

♦ Main flame failure ♦ Main gas valve not opened.

♦ Check the electrical connections to ensure they

are all securely connected.

♦ Check the two safety shut off valves. Replace if

defective.

Loading...

Loading...