6

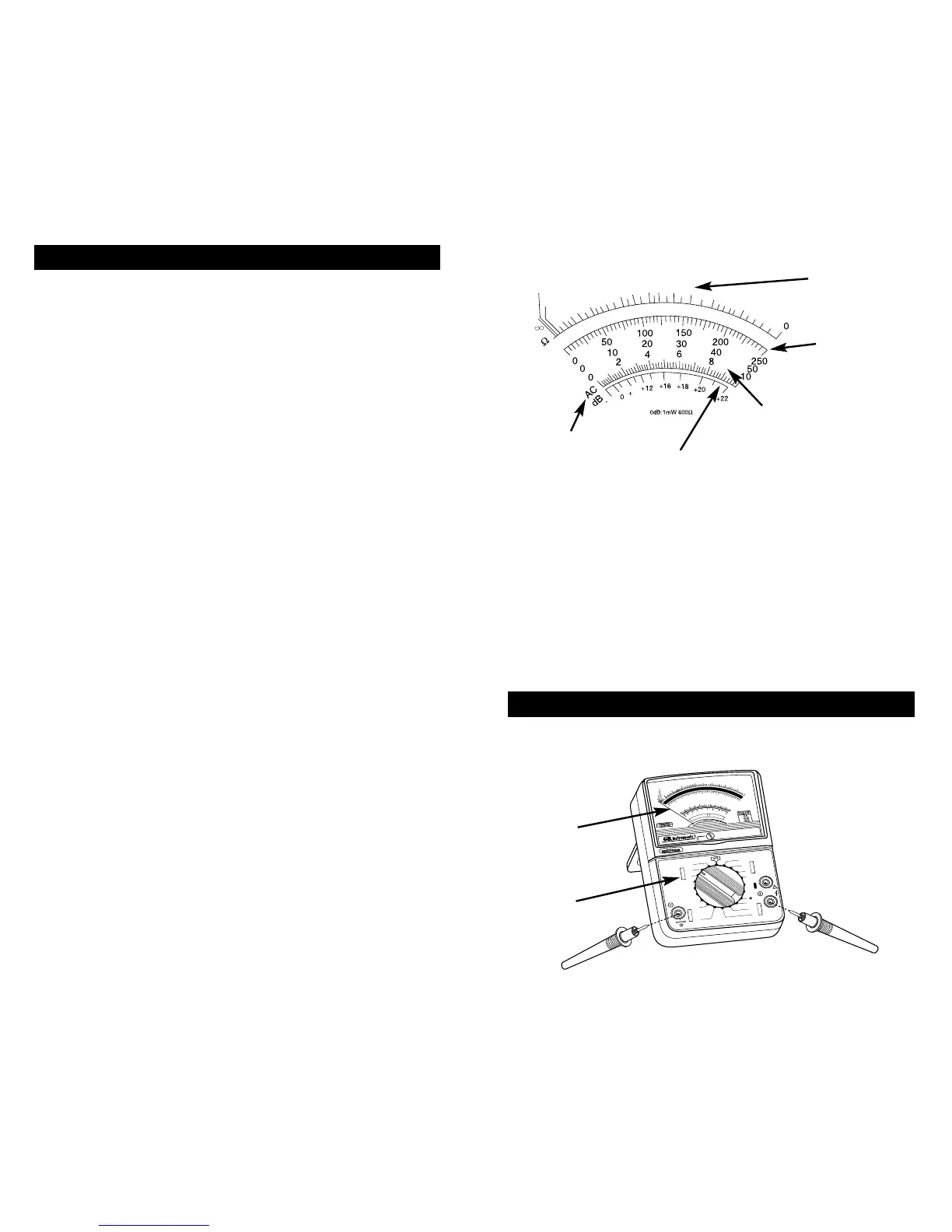

3.2 Check Condition of Internal Battery

Before making resistance or continuity tests, check the

condition of the internal battery. First turn the function/range

switch to the ohms Rx1 position. Short the test leads together

and the needle indicator should deflect to the right side of the

scale. Keep the test leads shorted together while

simultaneously turning the zero ohms adjustment dial until the

needle indicates zero at the right side of the ohms scale. If the

needle will not zero, replace the batteries with two new 1.5 volt

AA size batteries (see Battery Replacement).

1) Fully seat the test leads in the correct input jacks, (-) black

lead, (+) red lead.

5

1) Set the function/range switch to the proper position

before making a measurement. When the voltage or

current is not known, it MUST be determined that the

capacity of the selected range will handle the amount of

voltage or current in the circuit (see #3 under “For Your

Safety”). Always start with the highest range in the

function. If the voltage applied falls within the range of

a lower setting, reset the function/range switch to the

appropriate setting for greatest accuracy of reading.

2) Avoid placing the tester in areas where vibration, dust or

dirt are present. Do not store the tester in excessively

hot, humid or damp places. This tester is a sensitive

measuring device and should be treated with the same

regard as other electrical and electronic devices.

3) Using the tester in areas with high magnetic fields can

result in inaccurate readings. For greatest accuracy of

reading, lay the tester on a flat, non-metallic surface.

4) When the tester is not in use, keep the function/range

switch in the OFF position. This keeps the needle

indicator from deflecting or “bouncing” excessively.

5) When disconnecting the test leads from the unit, always

grasp the leads where the input jacks meet the tester

housing. Never pull the leads out of the jacks by the

insulated wire or transport the tester using the test leads

as a carrying strap.

6) Never immerse the tester in water or solvents. To clean

the housing use a damp cloth with a minimal amount of

mild soap.

7) If the resistance (ohms) function of the tester is not going

to be used for a week or more, remove the internal

battery to avoid potential leaks that may damage the unit.

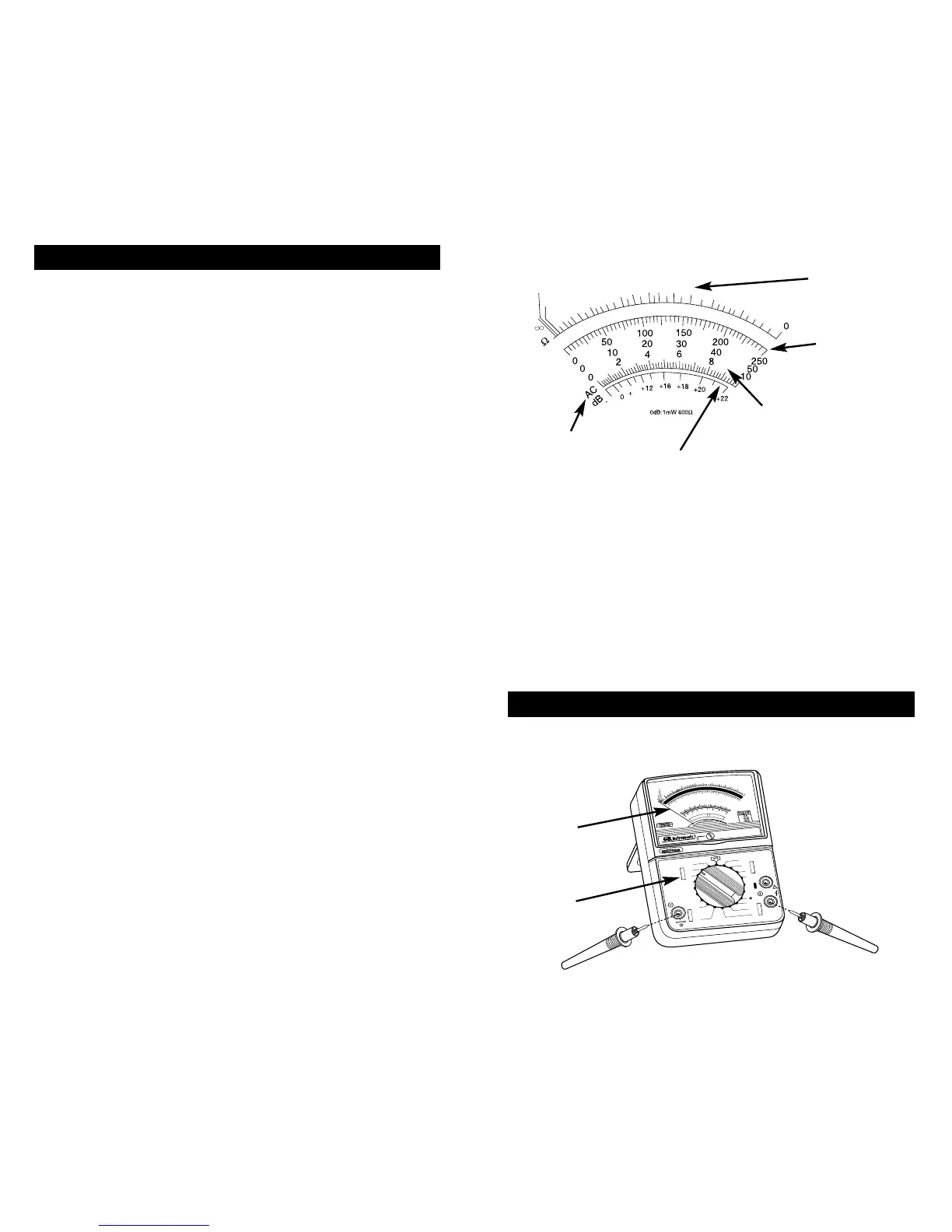

3.1 Preliminary Adjustments

Fully seat the test leads in the correct input jacks. If

necessary, using a small flat tip screwdriver, slowly turn the

mechanical zero adjustment screw clockwise or counter-

clockwise until the needle indicator is directly over the three

black zeros at the left end of the scale.

Loading...

Loading...