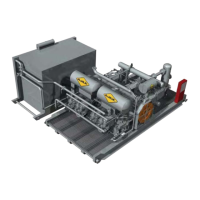

Why is the discharge gas temperature high in my GE H301 Air Compressor?

- NnicholasgarciaAug 5, 2025

High discharge gas temperature in your GE Air Compressor can stem from several causes. It could be due to excessive compression ratio because of leaking suction valves or piston rings. Other potential causes include high cylinder suction gas temperature, reduced cylinder suction pressure, leaking discharge valves or piston rings, fouled intercooler piping, improper lube oil, or a change in cylinder mode of operation. To resolve this, inspect and repair any leaking suction valves or piston rings, reduce the cylinder suction gas temperature, remove any restrictions affecting cylinder suction pressure, replace leaking discharge valves or piston rings, clean the intercooler piping, select appropriate lube oil and adjust the rate, and adjust the operation mode as required.