37

Integrity Test

Purpose

This test ensures that the membranes are intact and free

from tears or ruptures that would permit bacteria and other

particles to pass through the membranes, contaminating

the ltered water. The integrity test is conducted at initial

commissioning after the 15-minute ush and subsequent

sanitization and on an annual basis by a Homespring qualied

technician.

Test Description

This automated test will pressurize the membranes with air

from the outlet side of the system, forcing clean water back

through the membranes. Water easily passes through the

membranes due to the surface tension of water, however air

has a dierent surface tension and does not normally pass

through an intact membrane. Once adequate air pressure

has been achieved, a pressure sensor measures any decay of

that pressure. The integrity tester analyzes the pressure data

over this interval. If the decay is within acceptable limits the

integrity tester will indicate a ‘PASS’.

Tools Required

• Integrity tester • Cap wrench

• 2 lengths - 1/4" tubing • 2 - Pressure gauges

• 2 cups (500 ml) of unscented household chlorine

bleach (Clorox)

Other than the sanitizers, all required tools are included in the

service kit.

NOTE: A bucket may be required to collect some water if the

1/4" tubing is not long enough to reach a drain.

Disinfection Procedure for Tools

All pressure gauges and tubing MUST be disinfected prior

to use to avoid cross-contamination and introduction of

contaminated water into the household system.

Place and soak the adaptor tip and the 1/4” tubing ends in

5-6% unscented household chlorine bleach (Clorox) for 5

minutes. The brass adaptor will tarnish with time but this is

acceptable. Do not submerge the entire pressure gauge into

the sanitizer as it may damage it’s internal components. See

Figure 66.

Figure 66

1

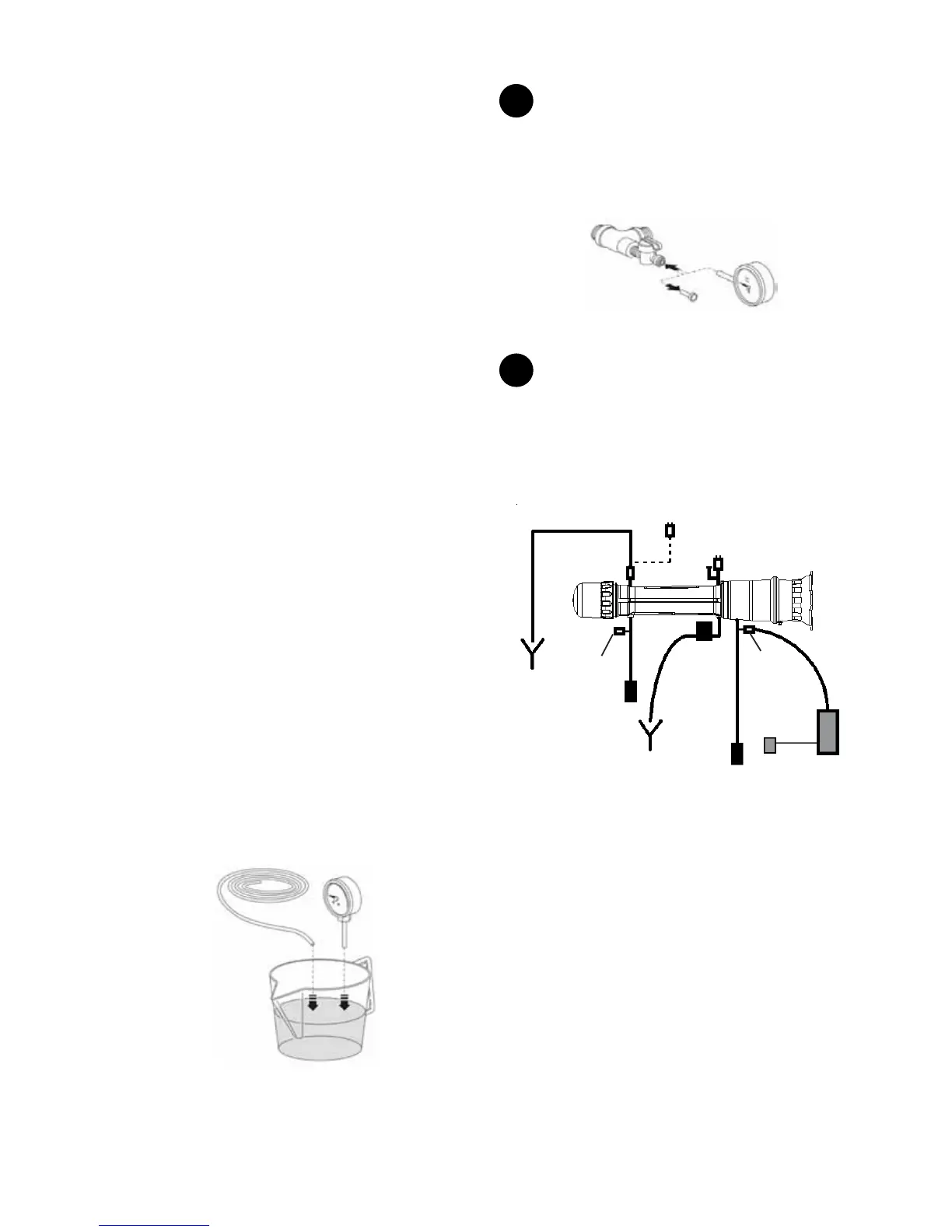

Close inlet and outlet valves. Use the controller to

initiate a manual ush sequence to bring the system pressure

to zero. Refer to the instructions in the Controller Functions

section on how to perform a manual ush sequence. Insert

pressure gauges into the inlet and outlet mini ball valves and

open the valves. Conrm that the system pressure is zero.

Figure 67

2

Remove the air relief valve near the system cap

(Figure 68) and replace it with the spare mini ball valve from

the installation kit. Insert 1/4" tubing into this mini ball valve,

direct this tubing to a drain or a pail. Open this mini ball valve.

Plug one end of the second 1/4" tubing into the outlet mini ball

valve and the other end into the integrity tester.

Inlet Mini

Ball

Valve

1/4”

tubing

Drain

Solenoid

Valve

Outlet

Mini Ball

Valve

Integrity

Te ster

Outlet

Valve

Inlet

Valve

Drain

1/4”

tubing

Drain

or pail

Air Vent

Assembly

Integrity

Te ster

Transformer

Remove

Air

Relief

Valve

Spare Mini

Ball Valve

Figure 68

Loading...

Loading...