Westfalia Separator

Mineraloil Systems GmbH 105

2051-9001-010 / 1205

4.5.1 Cleaning the separator

• Use only a cleaning agent that is approved for the field of application!

• Do not use acid or chloric cleaning agents.

Chlorine attacks stainless steel parts.

• Dissolve dried scale with citric acid.

• For cleaning the individual disks and bowl parts

Do not use metal scrapers and metal brushes!

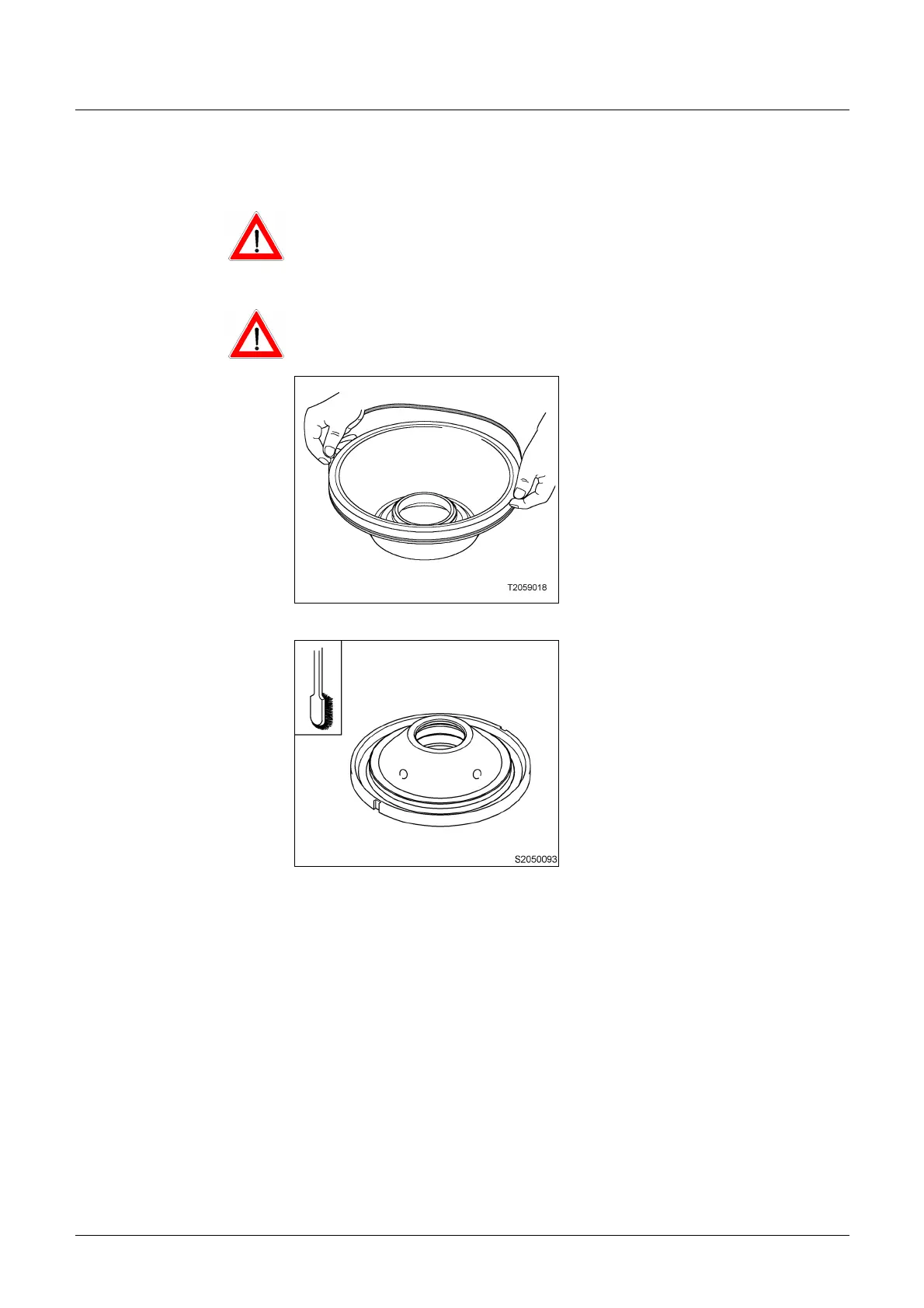

Fig. 179

• Take the gaskets out of the separa-

tor parts.

• Clean the grooves and gaskets to

avoid corrosion in the grooves.

• Replace damaged, very swollen,

hardened or brittle gaskets immedi-

ately.

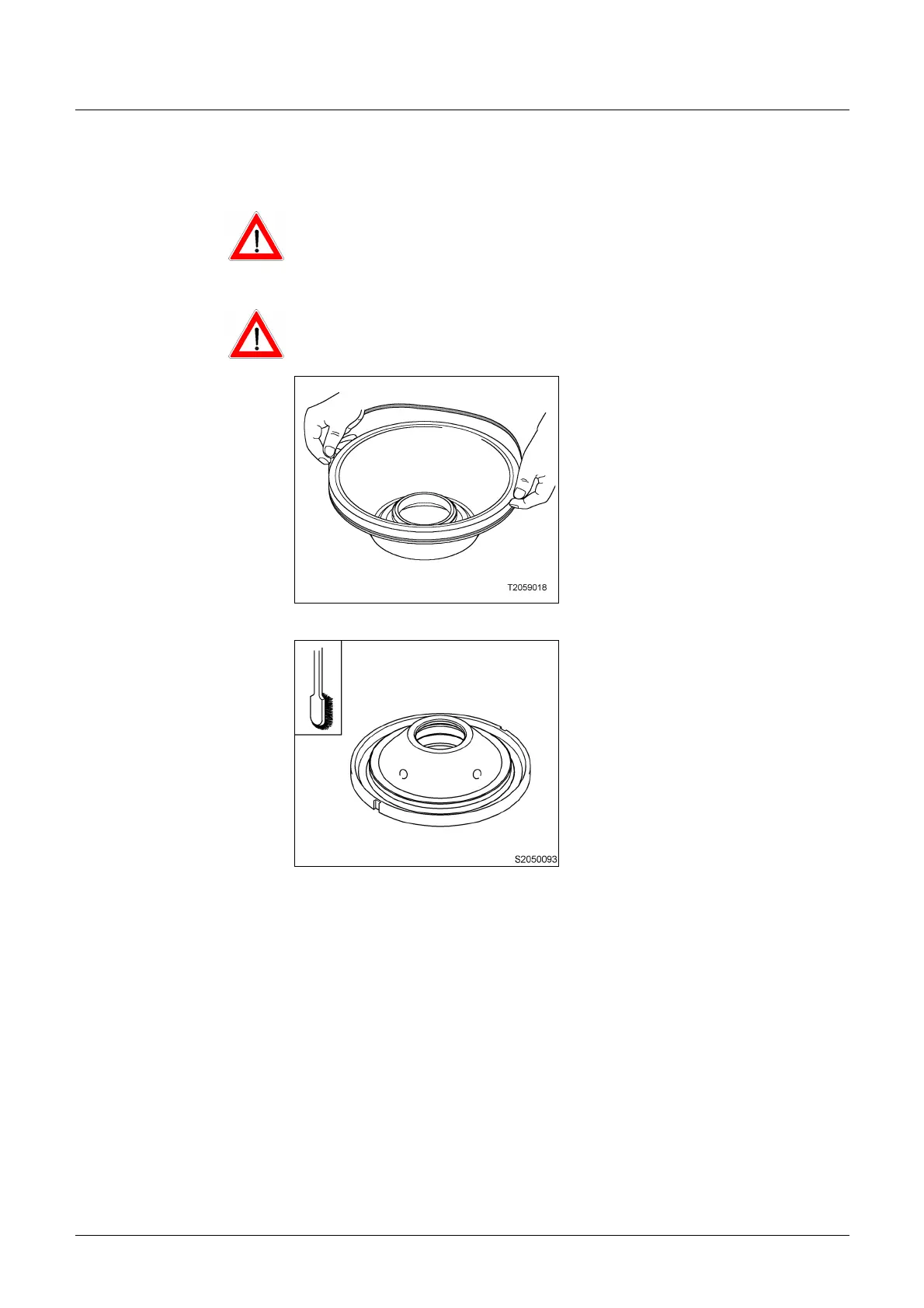

Fig. 180

• Clean the small holes at the bottom

with extra special care to ensure

trouble-free operation.

• Thoroughly clean the inlet bores of the spindle with a suitable cleaning agent

and brushes.

• Apply a thin coat of grease to the guide surfaces and threads of the separator

parts after drying (see 4.3.4 Lubrication schedule).

Loading...

Loading...