15

7 • PROGRAMMING

Notes:

- The output state can be reversed by setting its alarm to reverse (code AL for outputs

AL1 and AL2 and code Out for output AL3, in CFG.2 phase).

- The selection for outputs AL2 and AL3 is inoperative in case of configuration type

“relay not present” (see brd code)

Function “ArF” has priority over function “Out”..

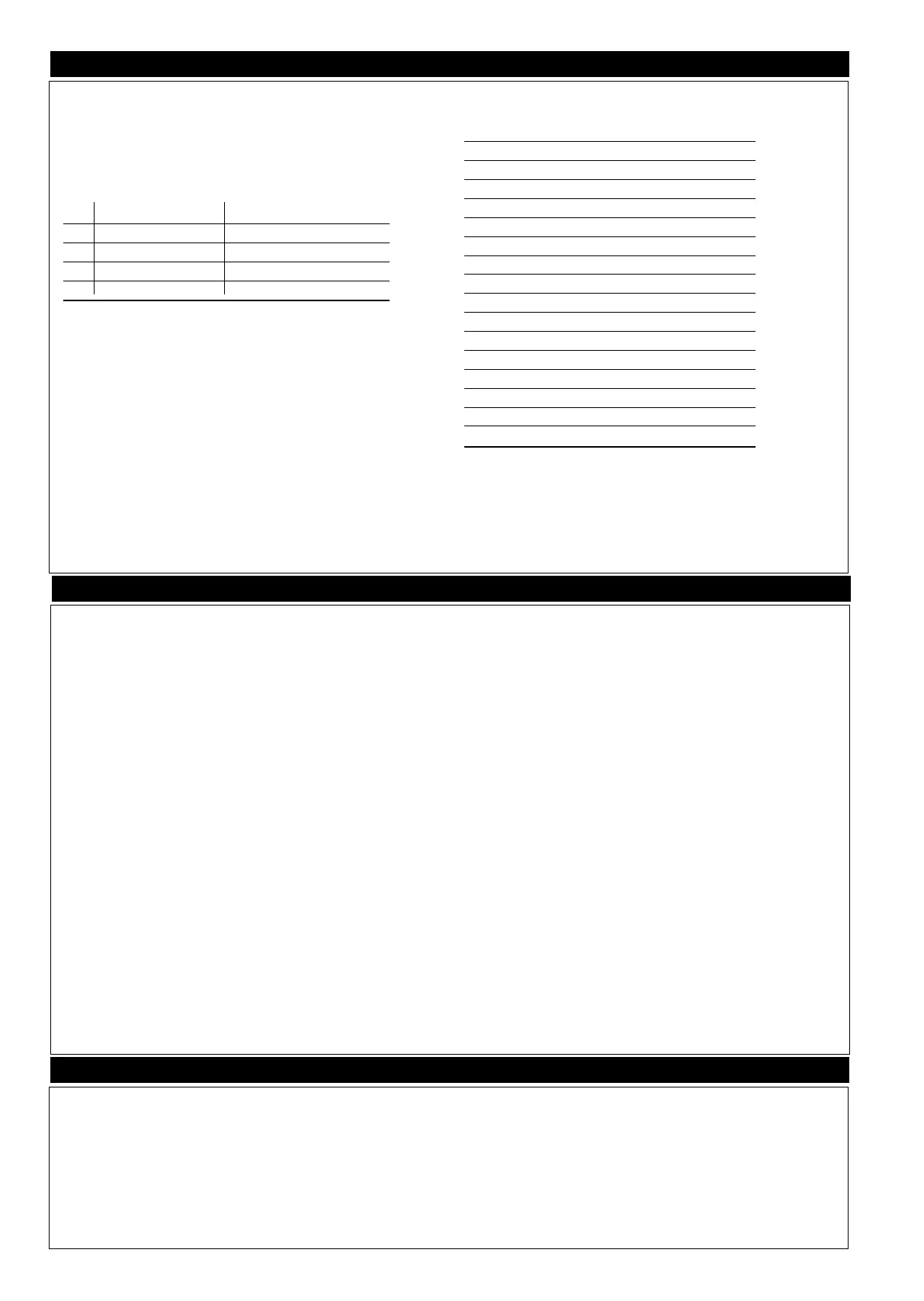

Ctr/ Selection of type of PID control and means of switching from automatic to manual

according to table:

Ctr PID Control for: Switching from Auto/Manual

0 Slow process (ts=8sec) with power man. saved

1 Fast process (ts=1sec) with power man. saved

2 Slow process (ts=8sec) with power autom. current

3 Fast process (ts=1sec) with power autom. current

Notes:

ts - sample time for actions I and D

A fast process is defined as one with main time constant less than 60 seconds. It is

advisable to disable the digital filter on the input in case of PID for fast processes (see

S.tu code in phase 0).

Hb.F/ Selection of type of HB alarm from 4 different choices:

0 - alarm trips when load current (CT input) drops below limit set for ON time of main

output

1 - alarm trips when ammeter full scale (Hb.S) in main output OFF time is exceeded

by 12%

2 - alarm trips if one of functions 0 and 1 (described above) is active. (OR logic

between functions 0 and 1)

3 - HB alarm for continuous output (PWM, setting _Ct = -1 or -2); does not take

account of ON/OFF times and presupposes a special ammeter card with hw integration

of load current.

Notes:

- code Hb.F is accessible only with ammeter input card installed (see

brd code) and

HB alarm enabled (code Out in CFG.2)

- see also ALARM FUNCTIONS / HB ALARM

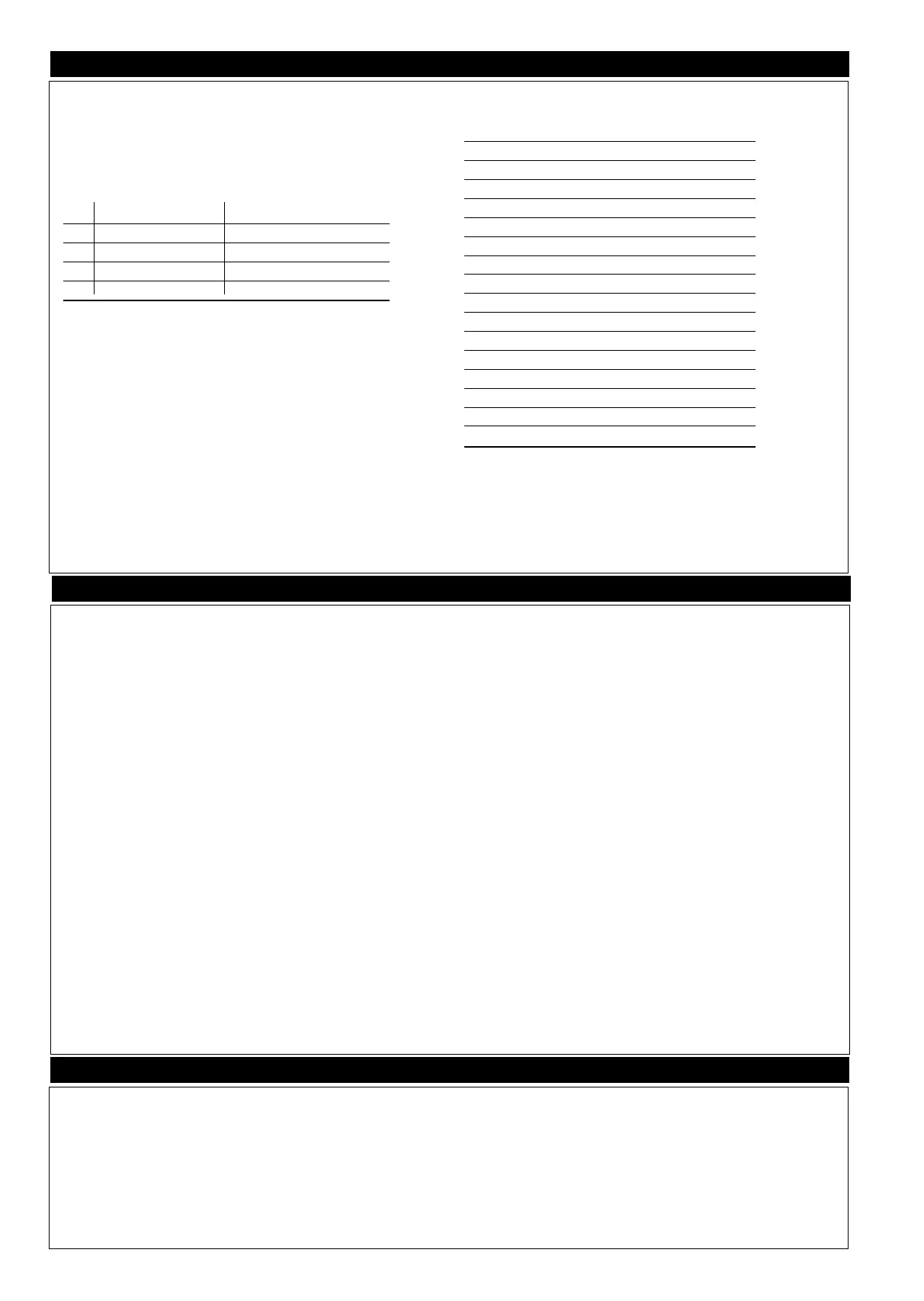

brd/ Hardware model code and enabling of automatic / manual (A/M) function

brd Display A/M Relay AL2 Relay AL3

0 3 digits disabled not installed not installed

2 4 digits disabled not installed not installed

4 3 digits enabled not installed not installed

6 4 digits enabled not installed not installed

8 3 digits disabled installed not installed

10 4 digits disabled installed not installed

12 3 digits enabled installed not installed

14 4 digitss enabled installed not installed

16 3 digits disabled not installed installed

18 4 digits disabled not installed installed

20 3 digits enabled not installed installed

22 4 digits enabled not installed installed

24 3 digits disabled installed installed

26 4 digits disabled installed installed

28 3 digits enabled installed installed

30 4 digits enabled installed installed

Add 64 to code to configure the model with input from current transformer.

Add 128 to code to configure the model with serial communication CL or 485.

Notes:

- The selected configurations must conform to the instrument’s hardware model. An

incorrect selection may cause functioning not conforming to specifications.

- The brd code can be changed only with jumper 6 closed (Hardware Configuration /

Inputs Card).

- The brd code is also available in calibration phase.

8 • CALIBRATION

Enable configuration and calibration as described in the manual in the Hardware

Configuration section (jumpers “3” and “6” closed).

In phase

CFG/2 (Configuration 2), set the type of input probe:

parameter

tyP:

tyP = 0,1,2,3,4,5 for thermocouples J,K.N.S R,T

tyP = 6,7 for resistance thermometers Pt100

typ = 8,9,10 for linear input 0 ..50mV

typ = 12,13,14 for linear input 10 ..50mV

tyP = 11 for resistance thermometers Pt100 special scale -19.9. .99.9

(199.9)°C with hardware modification.

Quit phase CFG/2: the instrument returns to normal operation. Proceed to calibration

with the instrument ON for at least 5-10 minutes. Calibrate as follows:

A) Calibration of thermocouples J,K,N,S,R,T and linear input 0-50mV10-50mV.

A.1

) Keep the F key pressed until CAL appears on the display; release F.

A.2) Connect a 50.00mV signal from a calibrator between terminals 1 (+) and 3 (-).

A.3) Press F: the display shows message CAL/50; wait about 6 seconds.

A.4) Press F: the display shows message t.A/25.0; with the raise and lower keys, set

the real value of the room temperature in which you are performing the calibration pro-

cedure (example: t.A = 23.7°C). You do not have to set the room temperature for linear

inputs.

A.5) Press F: the display shows brd/value; set the hardware model code (see brd

table in CFG.2 phase).

A.6) Press F to end the calibration procedure; the instrument will return to normal oper-

ation. If the 50mV signal remains in input, the display shows message

_Hi per tyP=

0,1,2,3,4,5 (thermocouples) or maximum scale for tyP = 8,9,10,12,13,14 (linear scale).

The thermocouple and linear input is now calibrated.

B) Calibration of Pt100 2/3 wires resistance thermometer input (tyP =6 or 7).

B.1) Keep the F key pressed until CAL appears on the display; release F.

B.2) Press F; the display shows message CAL/18; between terminals 1 and 3, connect

a resistance of 18.49 Ohms or a calibrator signal of -200.0°C; short circuit terminals 3

and 4; wait about 10 seconds.

B.3) Press F: the display shows message CAL/250; between terminals 1 and 3, con-

nect a resistance of 250.00 Ohms or a calibrator signal of +408.6°C; keep the short

between terminals 3 and 4; wait about 10 seconds.

B.4) Press F: the display shows brd/value; set the hardware model code (see brd

table in CFG.2 phase).

B.5) Press F to end the calibration procedure; the instrument will return to normal oper-

ation. If the 250 Ohm resistance remains in input, the display shows message _Hi. The

Pt100 input is now calibrated.

C) Calibration of Pt100 2/3 wires special scale resistance thermometer input (tyP = 11)

Before starting the calibration procedure, make sure the instrument hardware accepts

this type of input.

C.1) Keep the F key pressed until CAL appears on the display; release F.

C.2) Press F; the display shows message CAL/92; between terminals 1 and 3, connect

a resistance of 92.16 Ohms or a calibrator signal of -20.0°C; short circuit terminals 3

and 4; wait about 10 seconds.

C.3) Press F; the display shows message CAL/175; between terminals 1 and 3, con-

nect a resistance of 175.84 Ohms or a calibrator signal of +200.0°C; keep the short

between terminals 3 and 4; wait about 10 seconds.

C.4) Press F: the display shows brd/value; set the hardware model code (see brd

table in CFG.2 phase).

C.5) Press F to end the calibration procedure; the instrument will return to normal oper-

ation. If the 175.84 Ohm resistance remains in input, the display shows message

_Hi

for model 1000 and the value 199.9 for models 1001, 1101.

The Pt100 input is now calibrated.

D) Calibration of CT (ammeter) input for HB alarm.

The procedure is enabled only if the hardware accepts this type of input (see brd code

in CFG.2).

D.1) Keep the F key pressed until Hb.C appears on the upper display. Between fastons

6 and 7, connect a 5A AC signal.

D.2) Press the F key: the display shows message Hb.C/5; wait about 6 seconds.

D.3) Press the F key to end the CT input calibration procedure; the instrument will

return to normal operation. If the 5A current remains in the CT input, the current value

(accessible with key F) will show the set full scale (parameter Hb.S in phase CFG/1).

The CT input is now calibrated.

9 • CONTROL ACTIONS

Proportional Action: action in which the contribution on the output is proportional to the

deviation in input (deviation is the difference between the controlled variable and the

value you want).

Derivative Action: action in which the contribution on the output is proportional to the

speed of variation of the deviation in input.

Integral Action: action in which the contribution on the output is proportional to the inte-

gral in time of the deviation in input.

Influence of Proportional, Derivative and Integral actions on response of process

under control.

• Increasing the proportional band reduces oscillations but increases deviation.

• Reducing the proportional band reduces deviation but causes oscillations of the con-

trolled variable (excessively low proportional band values make the system unstable).

• Increasing derivative action corresponds to an increase of derivative time, reduces

deviation and avoids oscillations up to a critical value of derivative time, beyond which

deviation increases and extended oscillations occur.

• Increasing integral action corresponds to a reduction of integral time, tending to can-

cel deviation under normal working conditions between the controlled variable and the

value you want (setpoint).

If the integral time value is too long (weak Integral Action), there may be persistence of

the deviation between the controlled variable and the value you want.

In this case, you should reduce the proportional band and increase the Derivative and

Integral Actions until you get the result you want.

Loading...

Loading...