GREASING

Refer to the illustration and listing on the next page for

fitting locations. Wipe dirt from the fittings before

greasing them to prevent contamination. Replace any

missing or damaged fittings. To minimize dirt build-

up, avoid excessive greasing.

BASIC MACHINE

GREASE FITTING LOCATIONS

Every 50 Hours (or weekly)

Refer to the illustration on the facing page for loca-

tions.

--- BOOM AREA ---

1. Boom to frame upright pivot pins (2)

2. Rod end slave cylinder pivot pins (2)

3. Rod end lift cylinder pins (2)

4. Extend cylinder pivot pins (2)

5. Attachment carrier to boom nose pivot pins (2)

6. Tilt cylinder pivot pins (2)

7. Attachment carrier pivot pins (2)

8. Carrier linkage pivot pins (3)

9. Attachment release pins (2)

10. Attachment release lever pivot (1)

11. Boom slide pads - as required, front and rear

--- CHASSIS AREA ---

12. Brake foot pedal linkage (1)

13. Wheel spindle pins (4 per axle)

14. Tie rod ends (2 per axle)

15. Axle-to-frame pivot pins (1 per axle)

16. Drive shafts (3 per each)

17. Leveling cylinder pivot pins (2)

18. Base end lift cylinder pivot pins (2)

19. Base end slave cylinder pivot pins (2)

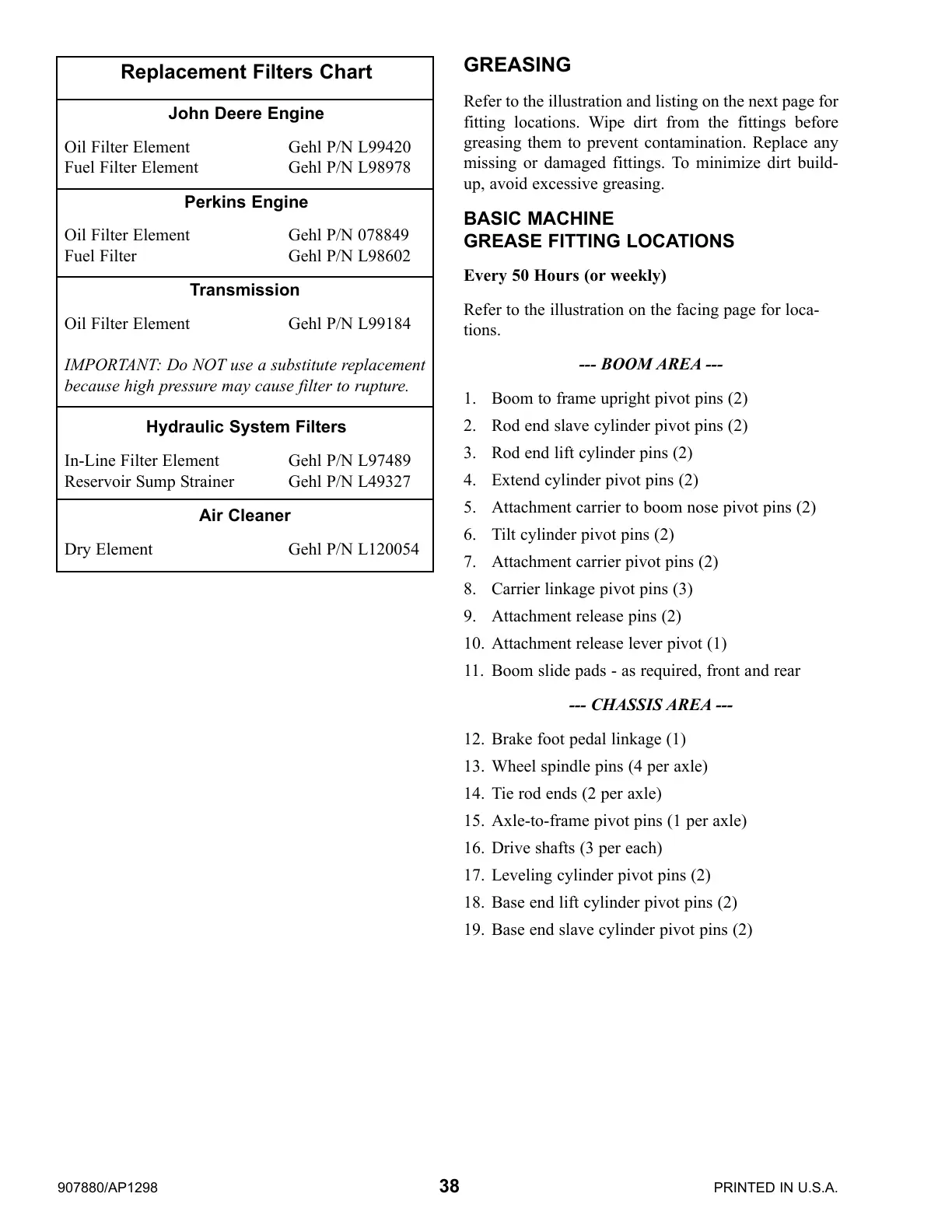

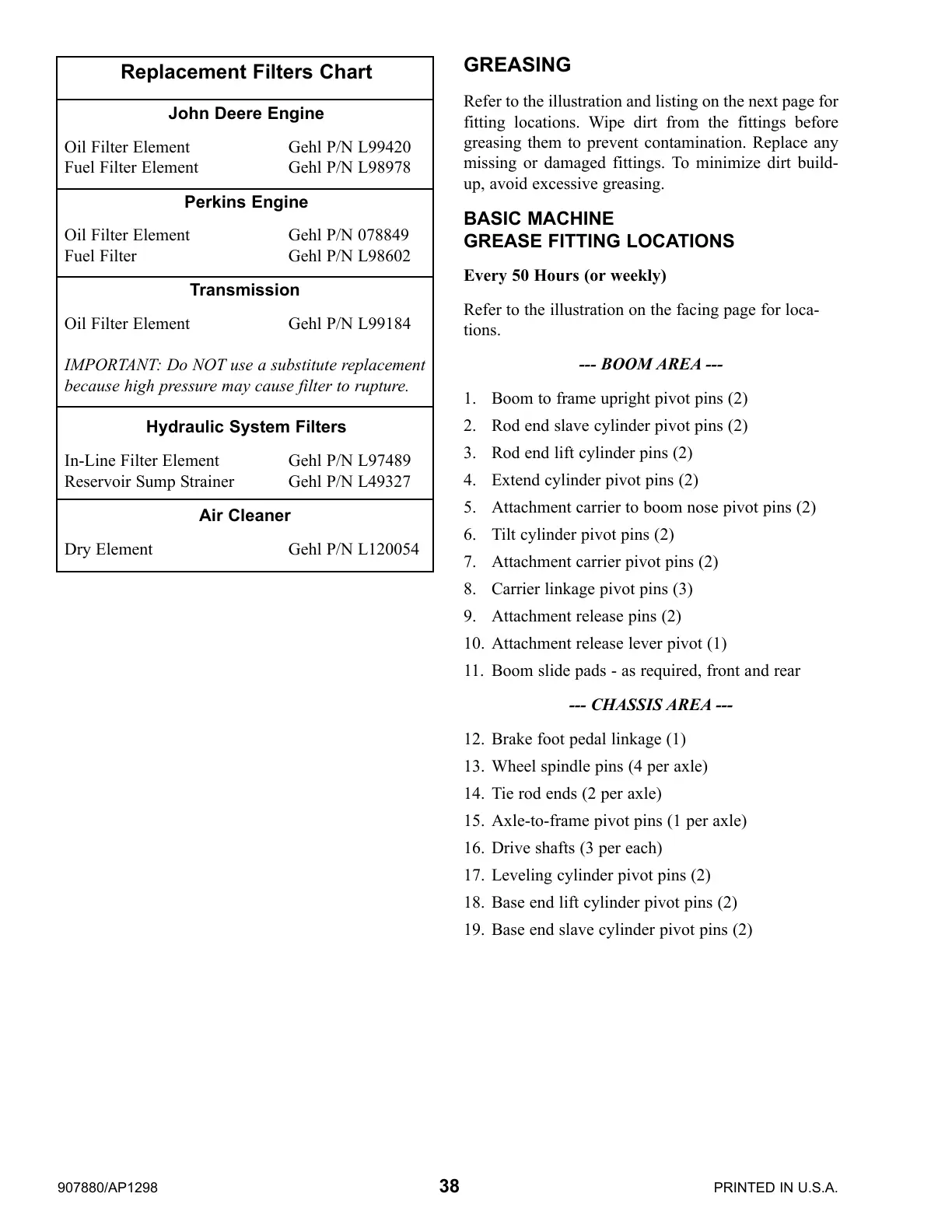

Replacement Filters Chart

John Deere Engine

Oil Filter Element Gehl P/N L99420

Fuel Filter Element Gehl P/N L98978

Perkins Engine

Oil Filter Element Gehl P/N 078849

Fuel Filter Gehl P/N L98602

Transmission

Oil Filter Element Gehl P/N L99184

IMPORTANT: Do NOT use a substitute replacement

because high pressure may cause filter to rupture.

Hydraulic System Filters

In-Line Filter Element Gehl P/N L97489

Reservoir Sump Strainer Gehl P/N L49327

Air Cleaner

Dry Element Gehl P/N L120054

907880/AP1298 38 PRINTED IN U.S.A.

Courtesy of CraneMarket.com

Loading...

Loading...