The following initial oil and filter changes should be

made at this time on a new machine. Thereafter these

changes should be made at the regular maintenance

schedule listed. Refer to those schedules for proce-

dures necessary.

Engine Oil and Filter (250 Hours)

Transmission Filter (1000 Hours)

Hydraulic Oil Filter (1000 Hours)

NOTE: Perform all other service requirements

up to this point as well as the following:

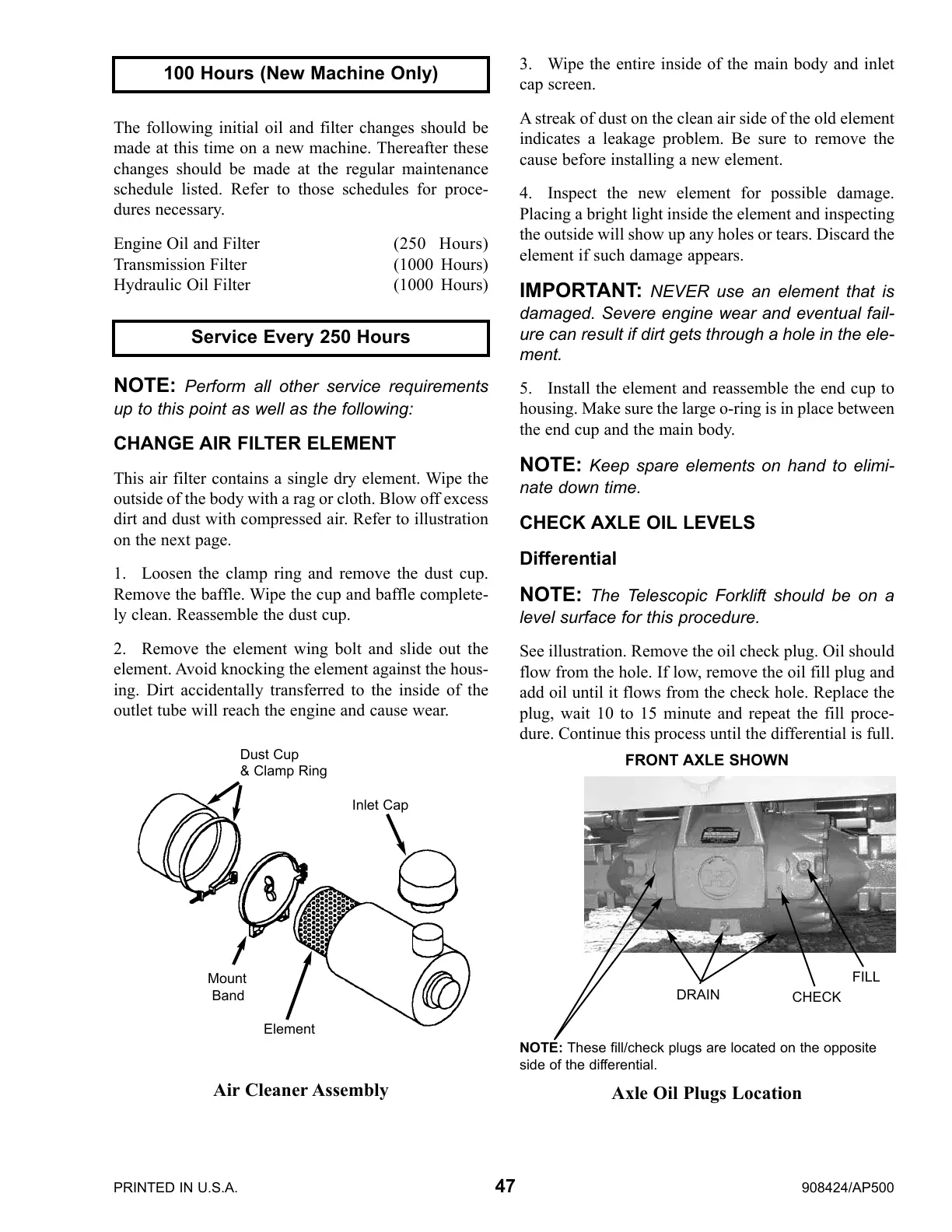

CHANGE AIR FILTER ELEMENT

This air filter contains a single dry element. Wipe the

outside of the body with a rag or cloth. Blow off excess

dirt and dust with compressed air. Refer to illustration

on the next page.

1. Loosen the clamp ring and remove the dust cup.

Remove the baffle. Wipe the cup and baffle complete-

ly clean. Reassemble the dust cup.

2. Remove the element wing bolt and slide out the

element. Avoid knocking the element against the hous-

ing. Dirt accidentally transferred to the inside of the

outlet tube will reach the engine and cause wear.

Service Every 250 Hours

100 Hours (New Machine Only)

3. Wipe the entire inside of the main body and inlet

cap screen.

A streak of dust on the clean air side of the old element

indicates a leakage problem. Be sure to remove the

cause before installing a new element.

4. Inspect the new element for possible damage.

Placing a bright light inside the element and inspecting

the outside will show up any holes or tears. Discard the

element if such damage appears.

IMPORTANT: NEVER use an element that is

damaged. Severe engine wear and eventual fail-

ure can result if dirt gets through a hole in the ele-

ment.

5. Install the element and reassemble the end cup to

housing. Make sure the large o-ring is in place between

the end cup and the main body.

NOTE: Keep spare elements on hand to elimi-

nate down time.

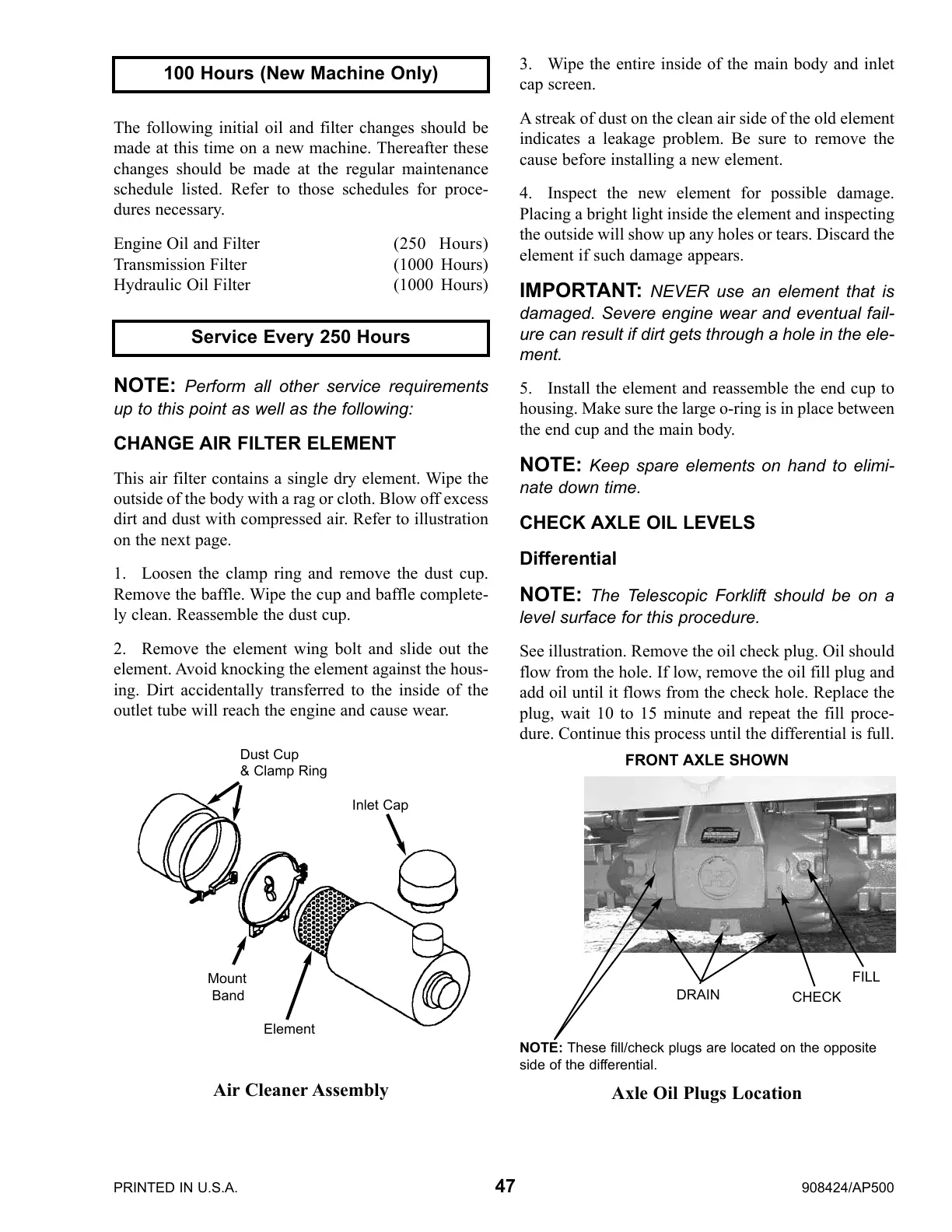

CHECK AXLE OIL LEVELS

Differential

NOTE: The Telescopic Forklift should be on a

level surface for this procedure.

See illustration. Remove the oil check plug. Oil should

flow from the hole. If low, remove the oil fill plug and

add oil until it flows from the check hole. Replace the

plug, wait 10 to 15 minute and repeat the fill proce-

dure. Continue this process until the differential is full.

Axle Oil Plugs Location

PRINTED IN U.S.A. 47 908424/AP500

Air Cleaner Assembly

Dust Cup

& Clamp Ring

Inlet Cap

Mount

Band

Element

FILL

CHECK

DRAIN

NOTE: These fill/check plugs are located on the opposite

side of the differential.

FRONT AXLE SHOWN

Courtesy of Crane.Market

Loading...

Loading...