Remove the top cover of the housing. Remove the ele-

ment and discard. Insert the new element onto the

housing and Replace the cover.

CHANGE AXLE DIFFERENTIAL

& PLANETARY OIL

Differential

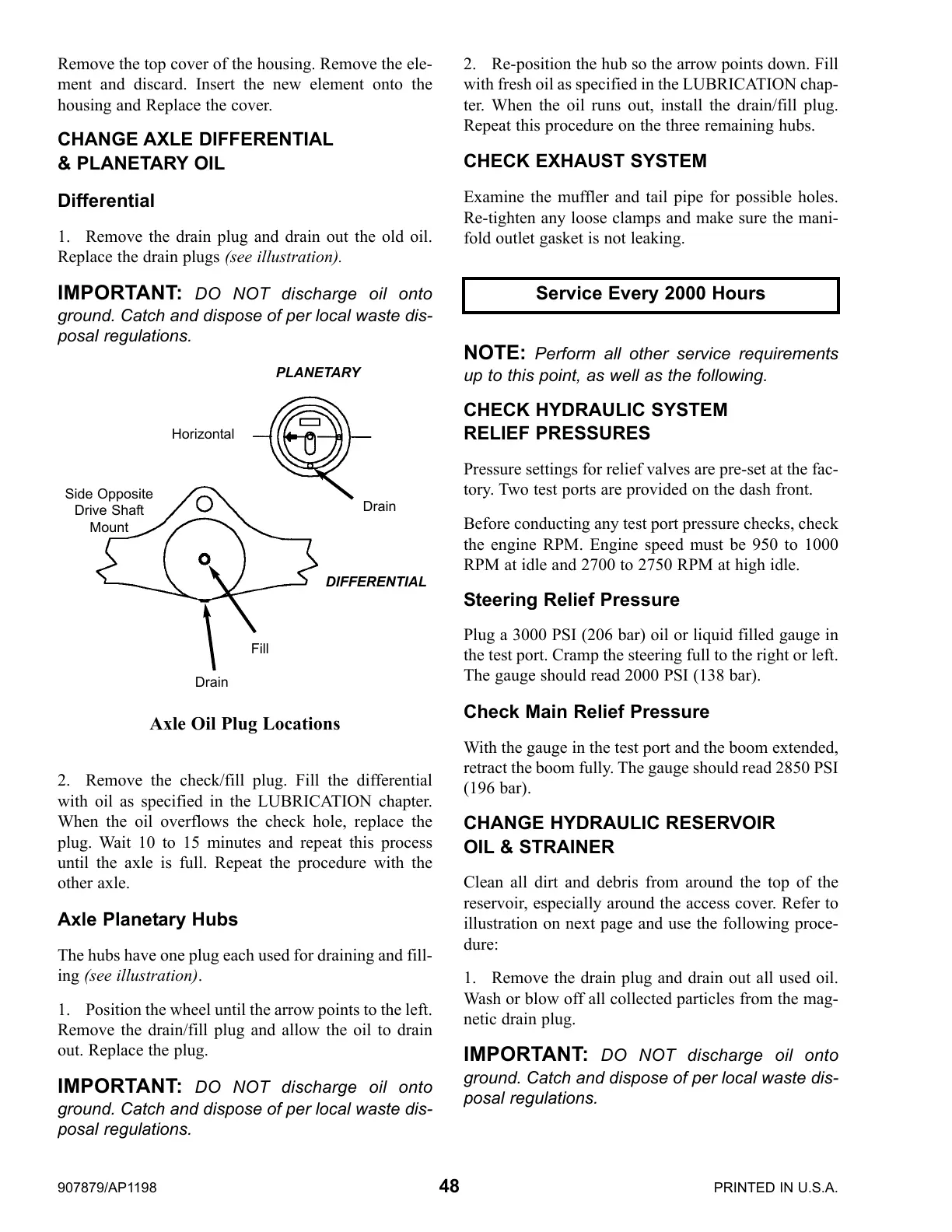

1. Remove the drain plug and drain out the old oil.

Replace the drain plugs (see illustration).

IMPORTANT: DO NOT discharge oil onto

ground. Catch and dispose of per local waste dis-

posal regulations.

2. Remove the check/fill plug. Fill the differential

with oil as specified in the LUBRICATION chapter.

When the oil overflows the check hole, replace the

plug. Wait 10 to 15 minutes and repeat this process

until the axle is full. Repeat the procedure with the

other axle.

Axle Planetary Hubs

The hubs have one plug each used for draining and fill-

ing (see illustration).

1. Position the wheel until the arrow points to the left.

Remove the drain/fill plug and allow the oil to drain

out. Replace the plug.

IMPORTANT: DO NOT discharge oil onto

ground. Catch and dispose of per local waste dis-

posal regulations.

2. Re-position the hub so the arrow points down. Fill

with fresh oil as specified in the LUBRICATION chap-

ter. When the oil runs out, install the drain/fill plug.

Repeat this procedure on the three remaining hubs.

CHECK EXHAUST SYSTEM

Examine the muffler and tail pipe for possible holes.

Re-tighten any loose clamps and make sure the mani-

fold outlet gasket is not leaking.

NOTE: Perform all other service requirements

up to this point, as well as the following.

CHECK HYDRAULIC SYSTEM

RELIEF PRESSURES

Pressure settings for relief valves are pre-set at the fac-

tory. Two test ports are provided on the dash front.

Before conducting any test port pressure checks, check

the engine RPM. Engine speed must be 950 to 1000

RPM at idle and 2700 to 2750 RPM at high idle.

Steering Relief Pressure

Plug a 3000 PSI (206 bar) oil or liquid filled gauge in

the test port. Cramp the steering full to the right or left.

The gauge should read 2000 PSI (138 bar).

Check Main Relief Pressure

With the gauge in the test port and the boom extended,

retract the boom fully. The gauge should read 2850 PSI

(196 bar).

CHANGE HYDRAULIC RESERVOIR

OIL & STRAINER

Clean all dirt and debris from around the top of the

reservoir, especially around the access cover. Refer to

illustration on next page and use the following proce-

dure:

1. Remove the drain plug and drain out all used oil.

Wash or blow off all collected particles from the mag-

netic drain plug.

IMPORTANT: DO NOT discharge oil onto

ground. Catch and dispose of per local waste dis-

posal regulations.

Service Every 2000 Hours

Axle Oil Plug Locations

PLANETARY

Horizontal

Drain

DIFFERENTIAL

Fill

Drain

Side Opposite

Drive Shaft

Mount

907879/AP1198 48 PRINTED IN U.S.A.

Courtesy of CraneMarket.com

Loading...

Loading...